Film Extrusion Line Provider

Table of Contents

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Nowadays, plastic films are used everywhere. These multipurpose materials are used in various industries, from the packaging that keeps our food fresh and medications sterile to the industrial films that protect items during transit and the agricultural covers that protect our crops. However, have you ever given any thought to the manufacturing process of these extraordinarily thin yet astonishingly robust films? Film extrusion is an advanced manufacturing technique that holds the key to the solution.The purpose of this essay is to explain the basics of film extrusion lines, discuss their significance, and show how Kriimpas India Pvt. Ltd. is a top supplier in this vital sector. We are the best Film Extrusion Line Manufacturer.

The basic foundation of the plastic film industry is film extrusion, which turns raw plastic pellets into the diverse range of films we see on a daily basis. The qualities of the finished product and, thus, the prosperity of the companies that depend on it are directly determined by the effectiveness, caliber, and capacities of the equipment employed in this process, the film extrusion line. Because of this, selecting a film extrusion line supplier is crucial for any business operating in the packaging or plastics sector.

What Exactly The Film Extrusion Line

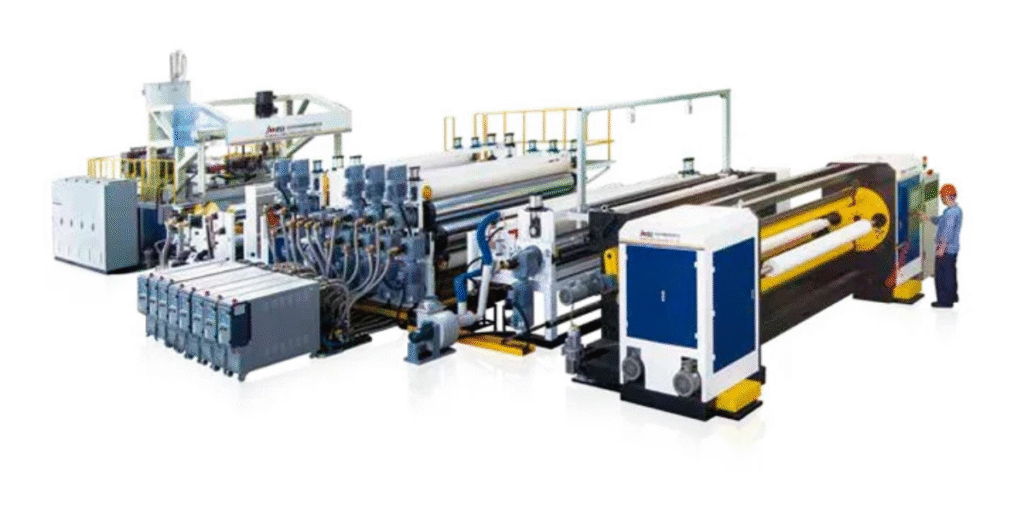

Let’s say you wish to create a very long, extremely thin plastic sheet. It cannot simply be rolled out like dough! A film extrusion line can help with that. A film extrusion line is essentially an advanced device that turns raw plastic material—typically in the form of tiny pellets or granules—into a continuous, thin film. Imagine it as a gigantic, plastic-specific pasta maker.

Why Choose Kriimpas India Pvt. Ltd

Your bottom line, product quality, and production efficiency can all be greatly impacted by your choice of film extrusion line supplier. The following explains why Kriimpas India Pvt. Ltd. is unique:

- Cutting-Edge Technology: Innovation is important to us. The most recent developments in automation, engineering, and design are integrated into our film extrusion systems. This implies that you receive extremely effective machines that provide exact control over each step of the extrusion process. We use technology to your advantage, from complex control systems for reliable film quality to improved screw designs for ideal melting.

- Sturdy and Dependable Construction: We recognize the financial impact of downtime. Kriimpas India’s machineries are therefore made to last. Our film extrusion lines are extremely robust and dependable, able to run continuously with no maintenance thanks to the use of premium materials and exacting manufacturing procedures. Your company will benefit from increased production and optimal uptime as a result.

- Customized Solutions Rather Than Off-the-Shelf: There is no one-size-fits-all strategy that we support. In close collaboration with you, our team of skilled engineers determines your budget, ideal film qualities, and particular production needs. By working together, we are able to create and deliver specially configured film extrusion lines that precisely match your company’s objectives. We can make it to your specifications, whether you require a flat film line for specialty packaging or a blown film line for agricultural film.

- Energy Efficiency for a Sustainable Future: Energy efficiency in the modern world is about environmental responsibility as much as financial savings. Energy-efficient film extrusion line design and production are top priorities for Kriimpas India. Our machines have power-saving features that help you cut operating expenses and make a positive impact on the environment.

- Complete After-Sales Support: We continue to be dedicated to our clients after the sale. In addition to installation, commissioning, operator training, and easily accessible spare parts, Kriimpas India offers full after-sales service. Your film extrusion line will continue to run smoothly and effectively for many years to come thanks to our committed service staff, who are always available by phone. We are committed to establishing enduring relationships with our customers.

- Proven Track Record and Expertise: Kriimpas India Pvt. Ltd. has years of experience in the field and a solid track record of providing a wide range of clients with effective film extrusion solutions. Our team is made up of highly qualified engineers and technicians with extensive knowledge of machine production and plastic processing. Selecting Kriimpas India means working with a partner who has a track record of achieving results.

- Value and Cost-Effectiveness: We are committed to providing outstanding return on your investment. We aim to offer affordable solutions that yield a quick return on investment, even though our machines have state-of-the-art technology and sturdy construction. Our mission is to assist you in effectively and financially achieving your production objectives.

Applications of Film Extrusion Line

- Food packaging includes films for fresh produce, frozen foods, snacks, bakery goods, dairy items, and retort pouches. The multi-layer blown film lines from Kriimpas India are capable of producing films with superior moisture and oxygen barrier qualities, increasing shelf life and maintaining freshness. For clear, flexible films used for sealing and wrapping, their cast film lines are perfect.

- Industrial packaging includes sturdy sacks for chemicals, fertilizers, and building supplies; protective films for tools and machinery; and long-lasting stretch wrap for palletizing products. For these demanding applications, Kriimpas India’s sturdy blown film lines guarantee excellent strength and resistance to punctures.

- Films for textiles, personal care items, detergents, and other domestic goods are examples of consumer goods packaging. These frequently need for superior printability and sealing qualities, which Kriimpas India’s lines are made to provide.

- Flexible Packaging: This category covers laminates, sachets, and stand-up pouches for a range of goods. Here, Kriimpas India’s co-extrusion capabilities are essential since they allow for the production of films with unique sealing, barrier, and aesthetic qualities. Their lines help to create robust, thin films that provide outstanding product visibility.

- Shrink and stretch films are essential for combining and safeguarding items during storage and transportation. They are made on both blown and cast film lines. For the best load stability, Kriimpas India’s equipment guarantees constant film tension and cling qualities.

- Greenhouse films are multi-layer films that provide light diffusion, thermal insulation, and UV stability for the best crop growth.

- Mulch films are used to control soil temperature, keep moisture in the soil, and inhibit weed growth, all of which lead to better crops and greater yields. The lines from Kriimpas India can effectively create thin, long-lasting mulch films.

- Silage films are used to preserve fodder and guarantee that cattle are fed high-quality feed. The blown film lines from Kriimpas India are made to provide the superior oxygen barrier and puncture resistance that these films demand.

Specification Table of Film Extrusion Line

| Parameter | Blown Film Extrusion Line | Cast Film Extrusion Line | Multi-Layer Film Line |

|---|---|---|---|

| Output Capacity | 20-300 kg/hr | 30-500 kg/hr | 50-800 kg/hr |

| Film Width | 100 mm to 3000 mm | 250 mm to 3500 mm | 250 mm to 3500 mm |

| Film Thickness Range | 10-200 microns | 12-250 microns | 15-300 microns |

| Number of Layers | Single / 2 / 3 / 5 Layer | Single / 2 / 3 Layer | 3 / 5 / 7 / 9 Layer |

| Extruder Sizes | 40 mm to 120 mm | 50 mm to 150 mm | 50 mm to 150 mm |

| Die Type | Spiral / IBC Die | T-Die | Multi-Manifold T-Die |

| Material Processed | LDPE, LLDPE, HDPE, PP, EVA | PP, PE, PS, PET, PVC | PE, PP, EVOH, Nylon |

| Winder Type | Surface / Center / Surface-Center | Surface Winder | Turret / Dual Surface |

| Power Consumption | 40-180 kW | 50-250 kW | 60-350 kW |

Advantage of Film Extrusion Line

- Technological Innovation at the Front: Innovation is ingrained in our DNA at Kriimpas. To take advantage of the most recent developments in film extrusion technology, we consistently invest in research and development. Our machines have sturdy designs, precision engineering, and sophisticated control systems that guarantee consistent production and peak performance. Kriimpas lines are designed for the future, whether it is for specialty film applications, multi-layer co-extrusion, or high-speed production.

- Unwavering Commitment to Quality: At Kriimpas, quality is a fundamental philosophy rather than merely a catchphrase. Strict quality inspections are performed on each part, assembly, and completed machine. We fulfill the most exacting industry standards by adhering to worldwide production norms, which guarantees that our lines are not only dependable and long-lasting but also produce outstanding film quality. Because of our sturdy build, your investment will last longer and have less downtime.

- A Totally Customer-Centric Approach: We don’t simply sell computers; we also think that long-term collaborations are important. Our staff takes the time to fully comprehend your unique production needs, preferred film qualities, financial limitations, and long-term growth objectives. Through this thorough conversation, we are able to suggest and tailor solutions that precisely match your company’s goals, guaranteeing that you will receive exactly what you require.

- Outstanding After-Sales Assistance — We’re Always Available to You: We are aware that continuous operations are essential to your success. Kriimpas takes pleasure in providing thorough and timely after-sales service because of this. When it comes to installation, commissioning, troubleshooting, and maintenance, our network of highly qualified experts is always available. We keep a large stock of authentic spare parts, guaranteeing prompt replacements and less downtime. Our top goal is keeping your production going.

- A Group of Professionals You Can Rely On: Our people are what make us strong. Experienced engineers, skilled designers, and committed technicians with a thorough understanding of film extrusion equipment and procedures make up the Kriimpas team. Every line we supply is painstakingly developed, carefully maintained throughout its lifecycle, and precisely built thanks to their combined knowledge.

Types of Film Extrusion Lines

Blown Film Extrusion Line

This is the most common type of film extrusion process. The molten plastic is extruded through a circular die to form a tube. Air is then blown into the tube to expand it, creating a thin film bubble. This bubble is cooled, collapsed, and wound into rolls.

Applications:

- Grocery and carry bags

- Packaging films

- Agricultural films

- Industrial liners

Cast Film Extrusion Line

In this type, the molten plastic is extruded through a flat die and immediately cooled on a chilled roller. This produces films with excellent clarity and surface finish.

Applications:

- Cling films

- Medical packaging

- Stretch wrap films

- High clarity food packaging

Multilayer Film Extrusion Line

Multilayer films are made by combining two or more layers of different plastics in a single film. This is achieved by feeding different polymers into separate extruders and then combining them in a co-extrusion die.

Applications:

- Barrier films for food packaging

- Lamination films

- Industrial packaging

- Specialized applications requiring strength and flexibility

Monolayer Film Extrusion Line

This produces a single layer of film, usually used for applications where high barrier properties or complex film structures are not required.

Applications:

- Shopping bags

- Disposable covers

- Liners for industrial use

Stretch Film Extrusion Line

Specially designed for producing stretchable plastic films used mainly for pallet wrapping and product bundling.

Applications:

- Stretch wraps

- Pallet covers

- Industrial bundling

Conclusion

At the core of the complex and vital world of plastic film is the potent technology of film extrusion lines. Any company striving for excellence in film production must have a thorough understanding of these machines’ operation and what to look for in a supplier.Your productivity, product quality, and long-term success are all greatly impacted by the film extrusion line supplier you choose, regardless of your level of experience as a manufacturer or your level of inexperience in the plastic film sector. We are the best Best Film Extrusion Line Provider.

As a dependable and forward-thinking partner, Kriimpas India Pvt. Ltd. stands out for their quality machinery, unmatched customer care, and persistent dedication to innovation. They offer solutions that enable companies to efficiently and sustainably make high-quality plastic films, rather than merely selling machinery.