Pipe Extrusion Lines Supplier

Introduction

Our range of offerings includes Processing Machinery for different Materials, Motion Based Solutions, Automation & Technological Solutions, Additive & Hybrid Manufacturing Solutions, and a wide array of spares and parts. Each product is meticulously engineered using the latest technology and premium quality raw materials sourced from reliable vendors. Our commitment to excellence ensures that our products meet stringent industry standards, delivering exceptional quality and performance. We are the best pipe extrusion lines provider in gujarat.

Pipe extrusion lines are essential to the manufacturing of pipes used in a variety of industries, including plumbing, irrigation, and even building. These lines are in charge of forming raw materials into accurate, premium pipes. Selecting the best pipe extrusion lines supplier is essential, regardless of whether you’re a manufacturing trying to streamline your production operations or a company looking to invest in pipe extrusion technologies.

We at Kriimpas India Pvt. Ltd. are pleased to provide cutting-edge pipe extrusion lines that are made to satisfy the demands of businesses all around the world. We are your go-to partner for smooth and effective production lines for the manufacture of premium pipes because of our years of experience and technical know-how.

What is a Pipe Extrusion Line?

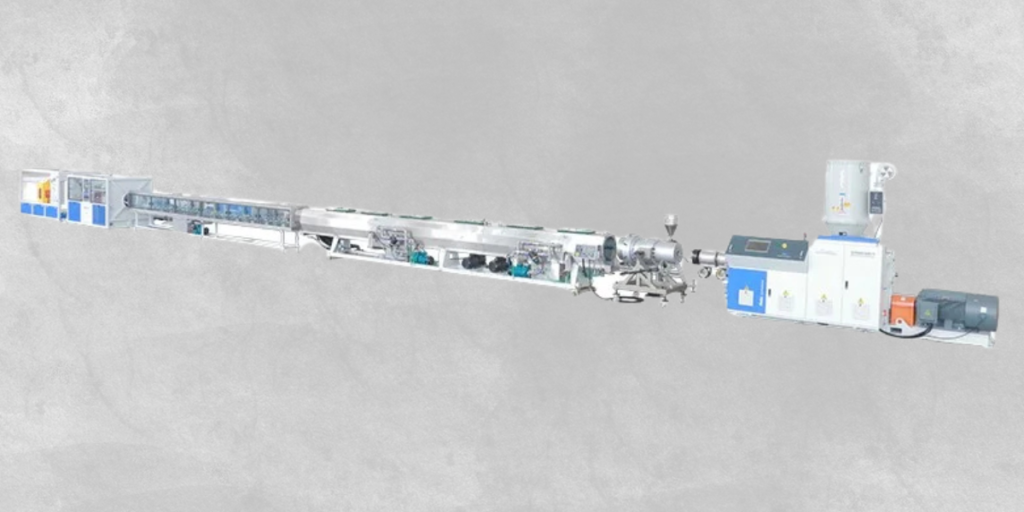

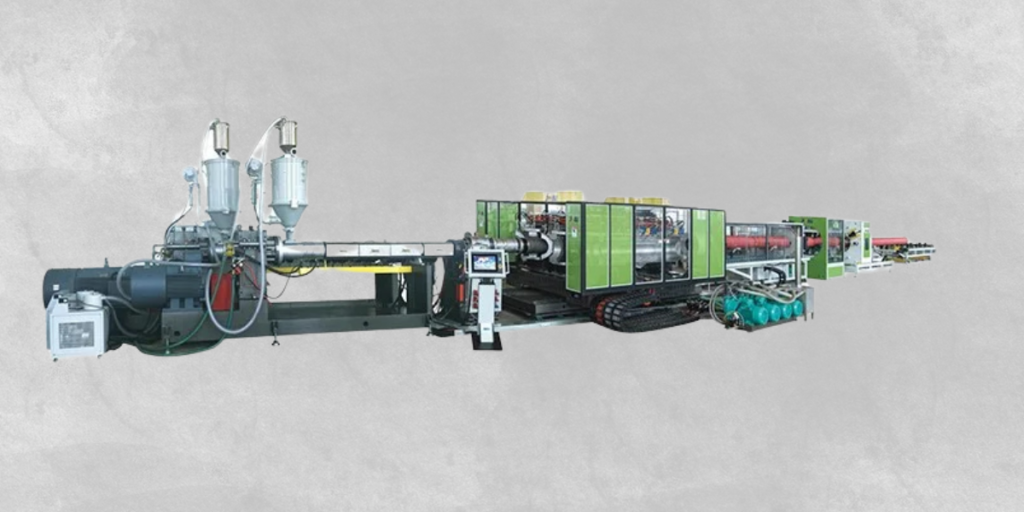

A pipe extrusion line is a device that uses the extrusion process to create plastic pipes, including PVC, HDPE, and PPR pipes. Raw plastic is supplied into a machine during the extrusion process, where it is melted, formed, and pushed into a mould to create a continuous pipe.

Extruders, dies, cooling tanks, haul-off units, cutters, and winders are some of the parts that make up pipe extrusion lines. Together, these techniques guarantee the efficient production of pipes with exact measurements and excellent quality.

Key Components of Pipe Extrusion Lines:

- Extruder: At the centre of the extrusion process is the extruder. It ensures that the plastic may be moulded into the required shape by heating and melting the raw material.

- Die: The die forms the appropriate pipe shape out of the melted material. It is essential for guaranteeing that the pipe’s internal structure, thickness, and diameter are all appropriate.

- Cooling Tank: The molten pipe must be cooled and solidified once it leaves the die. The pipe hardens in the proper shape thanks to the cooling tank, which is often supplied with water.

- The machine’s haul-off unit makes sure the pipe is drawn steadily during the cooling process to avoid distortion.

- Cutting Unit: After the pipes are created, they are cut to precise lengths using the cutting unit.

- Winder: A winder is used to coil pipes into rolls for convenient storage and transportation, especially flexible pipes.

Why Choose Pipe Extrusion Lines?

There are many advantages to using pipe extrusion lines, especially for businesses that need to produce pipes on a large scale. Among the main benefits are:

- High manufacturing Capacity: Continuous manufacturing made possible by pipe extrusion lines guarantees a large volume of pipes produced quickly. For companies that have to quickly meet demand, this is essential.

- Customisation: Manufacturers can create pipes of different thicknesses, diameters, and materials using an extrusion line, enabling customisation to satisfy particular needs.

- Consistent Quality: State-of-the-art extrusion lines guarantee that each pipe produced is of the same excellent quality and satisfies global standards. Defects and waste are decreased by this consistency.

- Cost-Effectiveness: Despite the seemingly high initial cost of a pipe extrusion line, long-term cost reductions result from the line’s capacity to produce vast numbers of pipes efficiently. Extrusion lines can also frequently be automated, which lowers labour expenses.

- Eco-Friendly: New pipe extrusion processes are made to use raw materials more efficiently and with less waste. This lessens the effect that pipe production has on the environment.

Types of Pipes Produced by Extrusion Lines

Several kinds of pipes are produced using pipe extrusion lines, including:

- PVC pipes are widely used in irrigation, drainage, and plumbing systems.

- High-density polyethylene pipes, or HDPE pipes, are perfect for subterranean utilities, gas delivery, and water distribution.

- PP Pipes: Suitable for industrial applications, polypropylene pipes can withstand high temperatures and chemicals.

- PEX Pipes: Heating systems and the delivery of potable water frequently use cross-linked polyethylene pipes.

- Multi-layer Pipes: These pipes have increased strength, resistance, and durability since they are composed of several layers of various materials.

The Benefits of Using Pipe Extrusion Lines

- High Efficiency: Pipe extrusion lines provide high-speed, continuous pipe production. This aids producers in satisfying the expanding need for plastic pipes across a range of industries.

- Consistency in Quality: The extrusion process’ accuracy and control guarantee that pipes are manufactured to precise specifications with little fluctuation in size or quality.

- Versatility: Pipe extrusion lines are appropriate for a variety of applications since they can create a large range of pipe sizes, forms, and materials. There are additional alternatives for customisation, enabling producers to design pipes that are suited to certain industry requirements.

- Cost-Effectiveness: A pipe extrusion line is a cost-effective alternative for pipe manufacturing because, despite the potentially large initial investment, it offers long-term advantages such as lower labour costs, more production capacity, and better quality control.

- Environmental friendliness: A lot of contemporary pipe extrusion lines are made with energy efficiency in mind, which helps to cut down on waste and energy usage. Additionally, certain devices can recycle plastic garbage, which promotes sustainability.

Conclusion

The production of premium plastic pipes used in a variety of sectors depends heavily on pipe extrusion facilities. Pipe makers may achieve great production efficiency, consistency, and cost-effectiveness with the correct extrusion line. We are the best pipe extrusion lines dealer.

As one of India’s top suppliers of pipe extrusion lines, Kriimpas India Pvt. Ltd. stands out for providing state-of-the-art technology, specialised solutions, and knowledgeable assistance to help pipe manufacturers meet their production targets. Whether you’re manufacturing multi-layer pipes, PVC, HDPE, or PP, Kriimpas India Pvt. Ltd. offers dependable and effective equipment that may be tailored to your needs.

You need go no farther than Kriimpas India Pvt. Ltd. if you’re searching for a reliable partner to deliver premium pipe extrusion lines. They are the best option for your pipe manufacturing needs because of their experience, knowledge, and dedication to quality.

Go to the Kriimpas India Pvt. Ltd. website right now to get a price or more details.