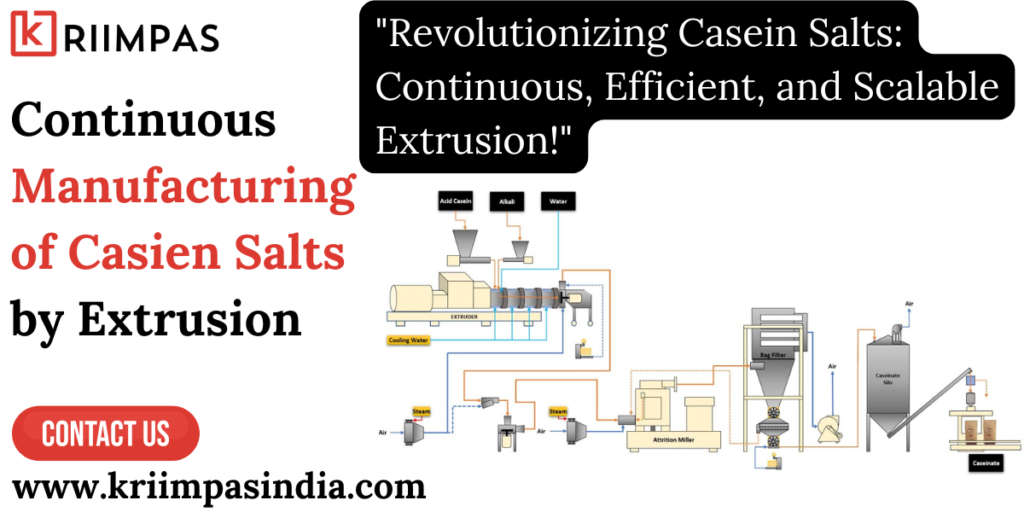

Continuous Manufacturing of Casien Salts by Extrusion

Continuous Manufacturing of Casien Salts/Continuous Manufacturing of Casien Salts by Extrusion/Process of Continuous Manufacturing of Casien Salts by Extrusion/Manufacturing of Casien Salts by Extrusion/Best Extruder Machines Provider/

Table of Contents

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers. We provide you the best machines for Continuous Manufacturing of Casien Salts by Extrusion.

An inventive and effective technique for producing high-quality casein salts on a large scale is the continuous manufacturing process of casein salts by extrusion. In sectors like animal feed, pharmaceuticals, and food production, this process is essential. We will go into great detail about the extrusion process and how it transforms the manufacturing of casein salts in this blog. We will also discuss the contribution of Kriimpas India Pvt. Ltd., a top supplier and service provider of auxiliary machinery and equipment that aid in extrusion process optimization.

What is Casein Salt?

The protein casein, which is present in milk, is the source of casein salt. Because casein has useful qualities like emulsification, water retention, and gel formation, it is utilized extensively in many industrial applications. In order to create casein salts, casein is neutralized with acids or alkalis. These salts are utilized as binding agents in animal feed, in nutritional supplements, and in the food and beverage sector. Better consistency, increased production rates, and lower operating costs are all made possible by the casein salts’ continuous manufacturing process.

The Extrusion Process Explained

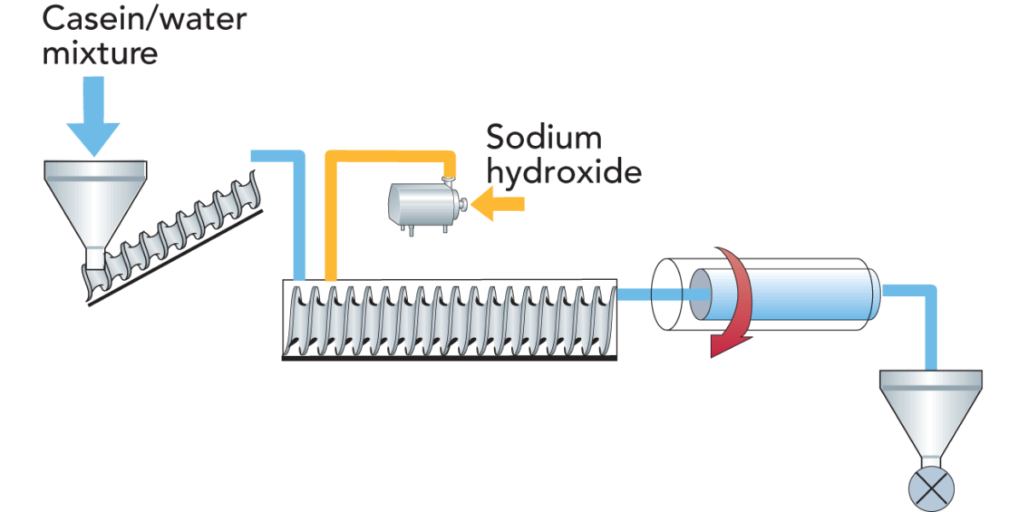

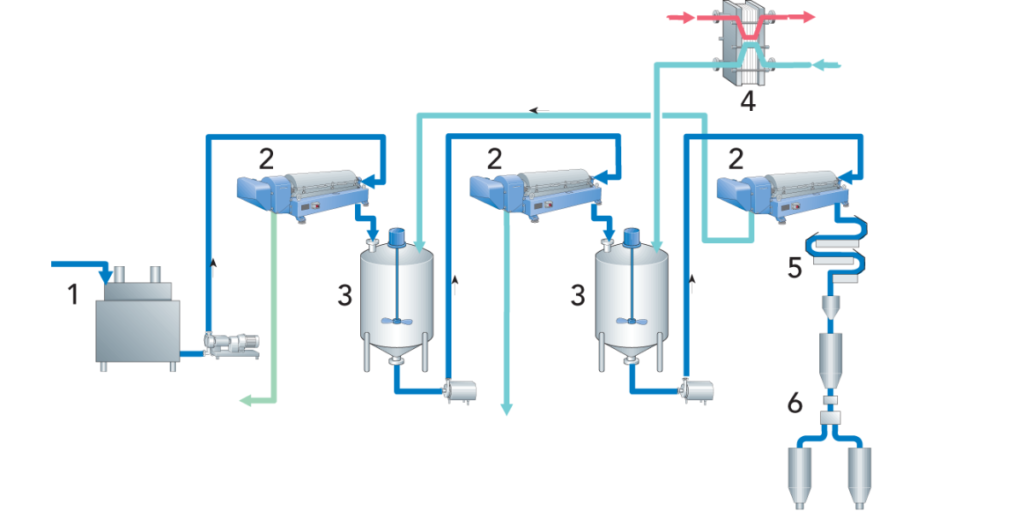

In the manufacturing process known as extrusion, raw materials are fed into a machine and forced through a die or mold at high temperatures and pressures. A continuous shape that can be further processed into the desired product is the end result of this process. Extrusion in the context of casein salts entails adding water, casein powder, and additional ingredients to an extruder. After the ingredients are combined, they are pushed through a die to form the final product’s shape. After cooling, the casein salts are sliced into the right size.

Key Components of the Extrusion Process

- Feeding System: A feeding system is used to supply the extruder with the raw materials, such as casein, water, and additional additives. A consistent and uniform feed is guaranteed by this system, which is important for the end product’s quality.

- Screw and Barrel: A revolving screw inside a barrel makes up the extruder’s core. The components are moved through the barrel by the rotating screw, where they are combined, heated, and compressed. The transformation of raw materials into the finished casein salts is facilitated by the high temperature and pressure.

- Die and Cutting System: A die forms the casein salt into the required shape after the extruded material passes through it. After that, the material is cut into the appropriate size and shape.

- Cooling and Drying: The casein salts are allowed to come to room temperature following extrusion. Cooling guarantees that the product keeps its structure and form. In certain situations, extra drying is carried out to get rid of extra moisture.

- Packaging: Finally, the casein salts are packaged for delivery to a range of sectors, including animal feed, food, and pharmaceuticals.

Benefits of Continuous Manufacturing by Extrusion

- High Efficiency: The raw materials are processed continuously because the extrusion process is continuous. Higher output and more effective use of resources result from this.

- Better Product Quality: The casein salts’ uniform quality is guaranteed by the regular mixing and molding of ingredients, which is crucial for their use in delicate industries.

- Cost-effective: Compared to conventional batch processing, continuous manufacturing via extrusion lowers labor and energy expenses. Additionally, the automation of the extrusion process reduces the possibility of human error.

- Versatility: Manufacturers can satisfy particular industry requirements by using extrusion to create casein salts in a range of sizes and shapes. To further improve the casein salts’ functionality, the procedure can be altered to include additional ingredients.

- Environmental Impact: Compared to other manufacturing techniques, the extrusion process is more environmentally friendly because it produces less waste and requires fewer chemical additives.

Casein Salts Applications

Because of their useful qualities, casein salts are utilized in many different industries. Typical uses include the following:

- Food Industry: Casein salts are utilized in dairy products, salad dressings, and baked goods as thickeners, stabilizers, and emulsifiers. They contribute to longer shelf life, better texture, and enhanced flavor.

- Animal Feed: Casein salts are used as a protein source in animal feed to help livestock and poultry grow and develop more effectively.

- Pharmaceutical Industry: Because casein salts work well as binders in tablet formulations, they are utilized in the manufacturing of medications and supplements. They aid in the controlled release of drugs as well.

- Nutritional Supplements: Because casein salts digest slowly and release amino acids into the body gradually, they are frequently found in protein supplements.

Why Choose Kriimpas India Pvt. Ltd.: Best Machines for Continuous Manufacturing of Casien Salts by Extrusion

Kriimpas India Pvt. Ltd. is a leader in offering state-of-the-art auxiliary machinery and services to support the ongoing extrusion-based casein salt manufacturing process. We supply you the best machines for Continuous Manufacturing of Casien Salts by Extrusion. Kriimpas India, a well-known supplier and service provider of extrusion machines, provides dependable, superior machinery that aids producers in streamlining their manufacturing processes.

- Extrusion Machine Supply: Kriimpas India provides cutting-edge extrusion equipment to meet a range of manufacturing requirements, including the production of casein salts. These devices are made to increase productivity and guarantee top-notch results.

- Tailored Solutions: Kriimpas India offers customized solutions for extrusion processes because it recognizes that every manufacturing process has different needs. The company’s equipment can be tailored to meet particular requirements, whether they are for the food, pharmaceutical, or animal feed industries.

- Technical Assistance: Kriimpas India takes great satisfaction in offering thorough technical assistance. The business guarantees that extrusion machines operate efficiently, reducing downtime and increasing production output, from installation to maintenance and troubleshooting.

- Training and Consultation: Kriimpas India provides training and consultation services to help clients optimize the advantages of extrusion. By assisting operators in comprehending the subtleties of the extrusion process, the team of experts guarantees consistent product quality and optimal performance.

- Maintenance and Upgrades: To keep extrusion machines functioning effectively, regular maintenance is essential. Kriimpas India provides machine upgrades and maintenance services to keep customers’ production lines using the newest technology.

Future Trends in Casein Salt Production

Several developments in extrusion technology are expected to influence the production of casein salt in the future. These are a few of the trends:

- Automation: Adding automation to extrusion operations will further cut labor expenses and mistakes. Manufacturers will be able to monitor and manage the extrusion process more effectively with the use of sophisticated sensors and AI-based systems.

- Sustainability: Manufacturers will concentrate on making the extrusion process more sustainable by lowering waste and energy consumption in light of growing environmental concerns.

- Personalization: The extrusion method will be more adaptable as the need for specific casein salts increases. In order to satisfy the particular requirements of various industries, manufacturers will be able to develop distinctive formulations.

- Quality Control: To guarantee that the finished product constantly satisfies the highest standards, improved quality control systems utilizing cutting-edge technologies like real-time monitoring and data analytics are needed.

- Research and Development: As extrusion technology continues to advance, new avenues for the production of casein salt will become available. Continued research and development will result in production techniques that are even more economical, ecologically friendly, and efficient.

Conclusion: Process of Continuous Manufacturing of Casien Salts by Extrusion

Extrusion is a cutting-edge method for producing casein salts continuously that offers many advantages to sectors in need of premium casein salts. Extrusion is the way of the future for casein salt production because of its high efficiency, enhanced product quality, and decreased environmental impact. By providing high-performance equipment, technical assistance, and tailored solutions to satisfy manufacturers’ changing needs, businesses such as Kriimpas India Pvt. Ltd. significantly contribute to improving the extrusion process. We are the Best Extruder Machines Provider in India.

Businesses can stay ahead of the competition in a cutthroat market by collaborating with Kriimpas India to optimize the efficiency, quality, and sustainability of their casein salt production process.

Do not hesitate to get in touch with Kriimpas India Pvt. Ltd. for professional assistance if you want to improve your casein salt production process using the best extrusion machines available.