Vertical Feeders Provider in Gujarat

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

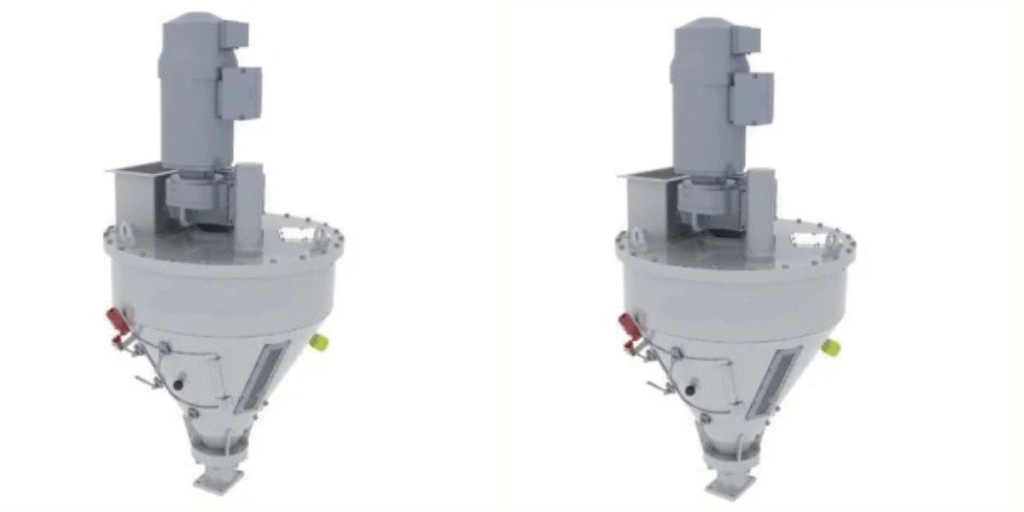

Gujarat, India’s industrial superpower, is a state known for its thriving manufacturing and unrelenting innovation. The state’s economic expansion is evidence of its forward-thinking strategy, from its thriving textile mills to its state-of-the-art pharmaceutical facilities, from sturdy building projects to expanding automotive plants. At the core of this advancement, which is frequently invisible but crucial, is a type of equipment known as vertical feeders, which guarantee seamless, uninterrupted, and effective operations. We are the best Vertical Feeders Manufacturer.

The foundation of automated material handling, these unsung heroes of the production line make sure that components, raw materials, and final goods all flow smoothly through intricate manufacturing processes. They are more than simply machines. Any Gujarati company looking to increase output, cut waste, and maintain flawless quality must comprehend and invest in the best vertical feeder solutions.

What Exactly Are Vertical Feeders

Think of a manufacturing facility like a well-tuned orchestra. Every machine or instrument must play its role with the appropriate rhythm and at the exact right time. Similar to conductors, vertical feeders make sure that materials are added to the process in a regulated, reliable, and frequently precisely aligned way.Simply put, a vertical feeder is a kind of material handling machinery made to raise and transfer bulk materials or individual parts vertically, frequently into a storage unit, processing line, or other machine. Vertical feeders make use of height, conserving important floor space and blending in smoothly with multi-level production setups, in contrast to horizontal conveyors that carry things along a flat surface. We are the best Vertical Feeders Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Personalized Solutions: Kriimpas India is aware that every facility, production line, and sector has different needs. There is no one-size-fits-all strategy that we support. In order to comprehend your unique material properties, intended throughput, space limitations, and integration requirements, our team of highly qualified engineers works closely with you. After that, we carefully design and build vertical feeders that will work best and blend in well with your current setup. We have the know-how to provide a high-capacity system for building materials, a highly accurate dosing device for medications, or a heavy-duty feeder for mining applications.

- Robust Engineering and Unwavering Quality: Due to the rigorous nature of industrial settings, equipment must be able to endure extreme circumstances and prolonged operation. Our vertical feeders are made with the best materials and sturdy construction, guaranteeing their remarkable endurance and durability. Throughout the manufacturing process, we maintain strict quality control procedures to ensure that our feeders are dependable and require little maintenance, which lowers operating costs and maximizes uptime.

- Advanced Automation and Control: Automation and control are crucial in today’s smart industries. The sophisticated control systems built into Kriimpas India Pvt. Ltd.’s vertical feeders enable exact feed rate modification, interconnection with other equipment, and even real-time data monitoring. This degree of automation improves productivity, lowers the need for human involvement, lowers the possibility of mistakes, and enables performance optimization based on real-time information.

- High Level of Material Handling Proficiency: Kriimpas India Pvt. Ltd. provides a wide range of material handling solutions; we are not only specialists in vertical feeders. Because of our vast experience, we are able to offer comprehensive solutions that smoothly integrate your vertical feeder with other essential parts including packing units, weigh batching systems, storage silos, and conveyors. Using a single, reliable supplier, this integrated strategy guarantees a seamless and effective flow of materials throughout your whole production process. Among the products in our portfolio are.

- Superb After-Sales Assistance and Support: We are dedicated to our customers long after the deal is complete. Installation help, staff training, preventative maintenance services, and timely technical support are all included in Kriimpas India Pvt. Ltd.’s extensive after-sales support package. Our objective is to optimize your return on investment and guarantee continuous operation of your vertical feeders. We are committed to establishing enduring alliances founded on mutual respect and achievement.

- Customer-Centric Approach: The customer is at the center of all we do at Kriimpas India. Prior to offering a solution, we place a high priority on comprehending your unique goals and obstacles. We stand out for our open lines of communication, teamwork, and commitment to deadlines. We are your progress partners, not just providers.

- Reliability and Quality Assurance: The cornerstone of our business is quality. To guarantee optimum performance, dependability, and safety, Kriimpas India rigorously tests and inspects each vertical feeder it manufactures. We follow strict industry guidelines, so you can be sure that your investment will continue to produce steady returns for many years to come.

Applications of Vertical Feeders

1. Pharmaceutical Industry

- Vertical feeders are used to feed blister packaging machines, filling machines, and labeling systems with tablets, capsules, vials, and syringes. Their precise and sterile operation is ideal for medical-grade environments.

2. Food & Beverage Industry

- Used for feeding items such as packets, bottles, or cans into the conveyor system for filling, sealing, or packing. These feeders are often integrated with inspection systems to ensure hygiene and safety.

3. Packaging Industry

- Whether it is pouches, cartons, or trays, vertical feeders help in feeding empty or filled items into packing lines. They are used in FMCG and retail packaging plants extensively.

4. Automotive Industry

- In component assembly, vertical feeders are used to orient and feed screws, washers, or auto parts into robotic arms or assembly machines.

5. Electronics & Electrical Industry

- Feeding delicate components such as circuit boards, chips, or cable fittings requires high precision – which vertical feeders provide efficiently.

6. Cosmetic & Chemical Industry

- Bottles, tubes, and containers are fed into labeling or filling machines, ensuring smooth continuous operation.

7. Plastic & Injection Molding

- Feeding molded parts or containers for further processing like labeling, printing, or inspection.

8. Agricultural Industry

- Used in packaging fertilizers, seeds, and agricultural chemicals in pouches or containers.

Technical Specifications of Vertical Feeders

| Specification | Details |

|---|---|

| Material | Vertical Feeders |

| Feeder Type | Vertical Vibration Feeder |

| Feeding Capacity | 100 – 300 parts/min |

| Material Compatibility | Plastic, Metal, Rubber, Light Alloys |

| Power Supply | 220V / 50Hz (Customizable) |

| Power Consumption | 0.5 kW to 2.0 kW |

| Hopper Capacity | 25 to 80 Liters |

| Height Range | 500 mm – 2000 mm (Adjustable) |

| Feeding Bowl Size | 300 mm – 800 mm |

| Control System | PLC / Manual |

| Noise Level | < 70 dB |

| Frame Material | SS304 / MS with Powder Coating |

| Optional Features | Auto-stop sensor, Dust cover, Mobile base |

Advantages of Vertical Feeders

- Perhaps the most important is precision and accuracy. Whether a precise weight of powder or one item at a time, vertical feeders are excellent in dispensing accurate quantities of goods. This guarantees product uniformity, cuts down on material waste, and removes uncertainty. This accuracy is crucial for sectors where even a small difference can affect cost or quality.Types of Vertical Feeders We Offer at Kriimpas India Pvt. Ltd.

- High-Speed Operation and Enhanced Throughput: Speed is crucial in the cutthroat industry of today. Vertical feeders are made to feed quickly, which greatly boosts production lines’ output. They can swiftly and effectively manage a large number of items, which boosts output and shortens time to market.

- Decreased Material Waste: Inaccurate feeding results in material waste, which has a direct effect on a business’s profitability. Vertical feeders significantly reduce spillage, overfilling, and underfilling by precisely distributing amounts, which results in significant cost savings.

- Improved Automation and Lower Labor Costs: An essential component of automated manufacturing lines are vertical feeders. Businesses can lessen their dependency on manual labor for monotonous jobs by automating the feeding process, freeing up human resources for more intricate and valuable duties. This reduces the possibility of human error in addition to personnel costs.

- Better Product Quality: A higher-quality final product is strongly correlated with accurate and consistent feeding. The finished product has greater consistency, fewer flaws, and a higher overall quality standard when materials are introduced precisely and uniformly.

- Adaptability and Versatility: Contemporary vertical feeders are incredibly adaptable. They can be set up to work with a variety of product sizes, shapes, and compositions. Numerous systems allow for rapid product switching, which makes them extremely flexible in a variety of production scenarios and settings.

- Room Efficiency: Because of their vertical design, these feeders often take up less room than horizontal feeding systems, which makes them perfect for establishments with limited space. The factory floor area may be used more effectively thanks to this small design.

- Decreased Maintenance and Downtime: Robustly engineered vertical feeders are made to last. Because of their sturdy design and well-functioning mechanics, they break down less frequently and require less maintenance, which lowers downtime and increases operational efficiency.

- Integration with Current Systems: A large number of vertical feeder solutions are made to be easily integrated into current manufacturing lines, reducing the need for expensive alterations or comprehensive overhauls. For many production systems, this makes them a useful and affordable improvement.

Types of Vertical Feeders

1. Elevator Type Vertical Feeders

- These feeders work like a bucket elevator, lifting materials from a lower point to a higher one. They are ideal for powder, granule, or small component transfer in industries like food and chemicals.

- Best for: Grains, powders, pharmaceutical tablets, etc.

- Key Benefits: Dust-free operation, hygienic design

2. Vibratory Vertical Feeders

- These feeders use vibration to move parts upward along a spiral track. They are highly effective in feeding small, lightweight, and irregularly shaped parts.

- Best for: Electronics, fasteners, small mechanical parts

- Key Benefits: Precise control, low noise, minimal wear and tear

3. Screw (Auger) Type Vertical Feeders

- In this design, a rotating screw (auger) moves materials upward through a tube. It is most commonly used for powdery or semi-solid materials.

- Best for: Flour, cement, powdered chemicals

- Key Benefits: Sealed structure, efficient powder handling

4. Belt Conveyor Vertical Feeders

- Belt feeders use a continuous belt to carry parts or materials vertically. This is ideal for heavier components and bulk material transport.

- Best for: Packaged products, assembly parts

- Key Benefits: High load capacity, gentle handling

5. Rotary Bowl Type Vertical Feeders

- This type includes a rotating bowl that helps in orientation and feeding of parts vertically. Common in assembly and automation lines.

- Best for: Precision components like bearings, nuts, medical parts

- Key Benefits: High-speed feeding, compact footprint

Conclusion

Gujarat was establishing the foundation for its future industrial supremacy in The workhorses were the seemingly straightforward but crucial devices, such as vertical feeders, which made sure that the materials moved smoothly and powered companies all throughout the state. They were and still are essential for increasing productivity, making the most use of available space, and guaranteeing the quality of the final product. We are the best Best Vertical Feeders Provider.

The demand for dependable, high-performing vertical feeders is still critical as industries develop and grow. This ongoing need is demonstrated by Kriimpas India Pvt. Ltd., which has a history of providing high-quality, individualized, and cutting-edge solutions. In the decades to come, we are dedicated to providing Indian companies with the most reliable and efficient material handling solutions, and we are honored to have been a part of Gujarat’s industrial adventure since For a smooth and effective future, pick Kriimpas India Pvt. Ltd. as your reliable partner for vertical feeders and complete material handling systems.