PVC WPC Panel Board Extrusion Line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

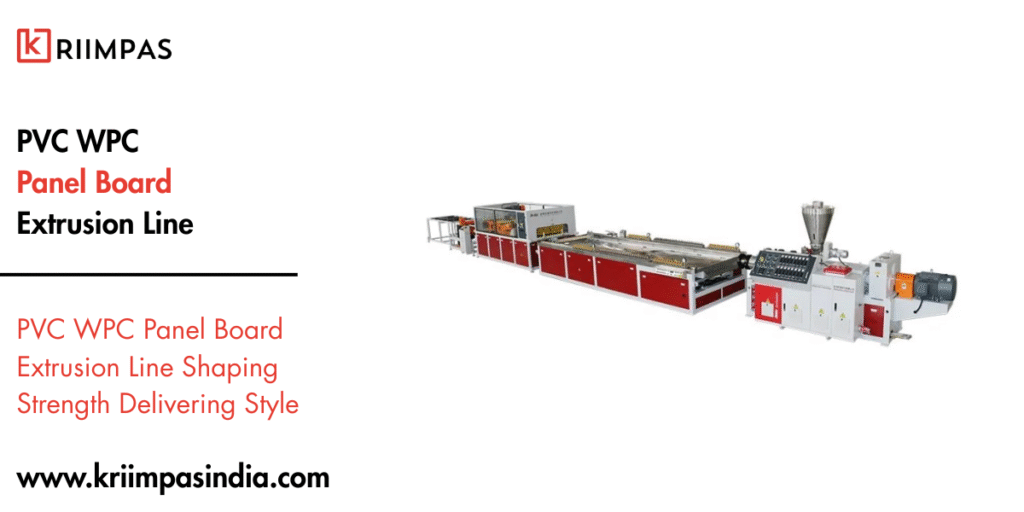

In today’s competitive building materials market, manufacturers need machinery that delivers precision, consistency, and cost-efficiency. The PVC WPC Panel Board Extrusion Line has emerged as a go-to solution for producing high-quality PVC and WPC Wood Plastic Composite panel boards used in interiors, exteriors, furniture, and modular construction. At Kriimpas India Pvt. Ltd, we understand that the right extrusion line doesn’t just produce panels, it transforms a factory’s productivity, product range, and profit margins. The need for long-lasting, low-maintenance, and visually pleasing panels is growing in today’s interior design and construction sectors.

PVC and WPC (Wood Plastic Composite panel boards combine the greatest qualities of wood and plastic to provide materials that are resistant to termites, dampness, and warping, while yet having the desired appearance and feel. Investing in a dependable PVC WPC Panel Board Extrusion Line is the single most crucial step for enterprises hoping to profit from this trend in order to grow production, guarantee constant quality, and increase profitability. We’ll go over how extrusion lines operate, what to look for, and why Kriimpas India Pvt. Ltd. We are the best PVC WPC Panel Board Extrusion Line Manufacturer.

What is a PVC WPC Panel Board

An integrated production system called a PVC WPC Panel Board Extrusion Line uses extrusion, calibration, cooling, cutting, and stacking processes to transform raw PVC/WPC (wood-plastic composite) compositions into completed panels. A raw material feeding system, a twin-screw or single-screw extruder depending on formulation, a specific die for panel shaping, vacuum calibrators, cooling tanks, haul-off units, and precision cutting and stacking equipment are the usual components of the system. Different panel widths, thicknesses, textures, and surface finishes can be accommodated by the fully automated setups. We are the best PVC WPC Panel Board Extrusion Line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Uncompromising Commitment to Quality: Every component in a Kriimpas line is “meticulously engineered using the latest technology and premium quality raw materials”. The emphasis on high-quality machine parts, from the robust extruder screw and barrel to precision dies, ensures optimal performance, longevity, and minimal downtime. This focus on quality directly translates to consistent, superior product output for your business.

- End-to-End Customisation and Support: Kriimpas operates on the principle of being a Trusted Partner for Customised & Standard Machinery Solution & Services. They engage with clients from the initial concept, designing a line that fits specific needs, whether for wall panels, ceiling panels, or decking profiles. Their support extends through assembly, testing, and after-sales service, ensuring a smooth production startup and ongoing operational efficiency.

- Driving Efficiency and Sustainability: Modern Kriimpas lines are designed for efficiency. Features like proper instrumentation and control systems allow for continuous monitoring of critical parameters screw speed, temperature, and vacuum levels, which is vital for maintaining product quality and physical properties. Furthermore, by enabling the production of WPC, a material that often utilises recycled wood and plastic, Kriimpas’s technology inherently supports sustainable manufacturing practices, helping businesses meet eco-friendly goals.

- Specialisation and Proven Expertise: Kriimpas has a distinct focus on extrusion technology, with the PVC WPC Panel Board Extrusion Line listed as a core product category. This specialisation means they possess deep, applied knowledge of the unique challenges in processing wood-plastic composites, from handling abrasive materials to achieving perfect surface finishes.

- Commitment to Quality and Innovation: Since its incorporation in Kriimpas has built its reputation on durability and reliability. Their machinery is engineered with high-grade materials and incorporates cutting-edge technology, such as energy-efficient drives and intelligent control systems, ensuring your investment remains productive and modern for years to come.

- Proven Industry Leadership: With a growing global presence and a diverse clientele across the construction, packaging, automotive, and aerospace sectors, Kriimpas has demonstrated its capability to deliver reliable solutions for demanding applications. Their focus on R&D and sustainable practices, including energy-efficient machine designs, aligns with the future of responsible manufacturing.

- Versatility in Product Range Large lines are often designed to handle a wider range of specifications. They can easily switch between producing different widths, thicknesses, and core materials like fire-retardant grades. This flexibility allows you to cater to diverse customer needs from architectural cladding to industrial partitions without needing multiple machines.

- Cutting-Edge Technology: Kriimpas incorporates the most recent developments in extrusion WPC Panel Board Extrusion Line. This implies that their equipment gives you a competitive edge through improved efficiency, higher-quality products, and lower energy use.

- Complete assistance: Kriimpas offers end-to-end assistance from the time you collaborate with them. This covers every aspect, including initial design and assembly, installation, maintenance, operator, WPC Panel Board Extrusion Line and spare part supply. Their knowledgeable support staff is always available to help.

- Customisation and Scalability: Your needs are unique. Whether you need a standard line or a highly customised solution for specific panel sizes or special raw material blends, we have the technical capability to design and deliver exactly what you need.

- Global Perspective with Local Presence As an Indian company with international experience, Kriimpas combines global technological standards with local market understanding. Their equipment meets international performance benchmarks while being optimised for operating conditions common in their primary markets. Additionally, their domestic manufacturing base facilitates responsive customer support and reduces lead times for equipment delivery and spare parts—advantages often unavailable with purely international suppliers.

Applications of PVC WPC Panel Board

1. Interior & Exterior Wall Panels

- Used for manufacturing durable PVC/WPC wall cladding

- Ideal for homes, offices, commercial spaces, hotels, and modular constructions

2. Ceiling Panel Production

- Produces lightweight and moisture-proof ceiling panels

- Suitable for bathrooms, kitchens, hospital ceilings, and decorative interiors

3. Modular Furniture & Cabinets

- Used to create WPC/PVC boards for modular kitchens, wardrobes, and storage units

- Termite-proof and long-lasting furniture applications

4. Door & Door Frame Manufacturing

- Extrusion line supports production of WPC/PVC solid & hollow doors

- Widely used in residential, institutional, and industrial door solutions

5. Decorative Panel Boards

- For producing high-quality decorative wall and partition panels

- Popular in interior designing, exhibitions, and partition systems

6. Packaging & Industrial Boards

- Used to manufacture impact-resistant PVC/WPC boards

- Suitable for industrial packaging, pallets, and protective sheets

7. Outdoor Applications

- Creates weather-resistant WPC boards

- Perfect for exterior cladding, fencing, garden furniture, and pergolas

Table of Specifications PVC WPC Panel Board

| Parameter | Specifications |

|---|---|

| Material | PVC WPC Panel Board Extrusion Line |

| Motor Power | 37–75 kW (depending on capacity) |

| Product Width | 1220 mm / Customized |

| Production Capacity | 300–800 kg/hr |

| Control System | PLC with touch panel |

| Cooling System | Water cooling calibration |

| Cutting Unit | Automatic saw cutter |

| Application | Wall panels, furniture boards, ceiling panels |

Advantages of PVC WPC Panel Board

- Superior Durability & Low Maintenance: These boards are highly resistant to moisture, rot, termites, and UV radiation, making them ideal for both indoor and outdoor applications without the need for constant staining or sealing.

- Eco-Conscious Manufacturing: WPC panels make excellent use of recycled wood and plastic materials, supporting a circular economy. Kriimpas India further enhances this sustainability through energy-efficient machine designs that minimise waste and power consumption.

- Design Flexibility: The extrusion process allows for incredible versatility in profiles. Manufacturers can produce boards in a vast array of colours, textures, including realistic wood grains and dimensional profiles to meet specific architectural and consumer demands.

- Engineered Durability: WPC and PVC boards offer excellent resistance to moisture, rot, and insect infestation, problems that commonly plague natural wood. They are also formulated to be fire-retardant and possess high impact strength, ensuring longevity in demanding environments.

- The Sustainable Choice: Kriimpas champions green manufacturing. WPC boards utilise recycled wood fibres and can incorporate recycled plastics, giving new life to post-industrial waste. Furthermore, the products themselves are recyclable at the end of their long service life, supporting a circular economy and helping our partners meet their environmental goals.

- High Output & Automation: Engineered for continuous, high-volume production, our lines, such as those featuring the conical twin-screw extruder, can achieve outputs ranging from. The fully automated process, governed by a central PLC control system, minimises manual intervention, reduces labour costs, and ensures round-the-clock productivity.

- Operational Efficiency and Scalability Modern extrusion technology is designed for productivity. A Kriimpas line streamlines the manufacturing process, integrating raw material feeding, extrusion, cooling, haul-off, and cutting into a seamless, automated workflow. This minimises manual handling, reduces waste, and maximises output. Furthermore, Kriimpas designs scalable solutions that can grow with a business, allowing for capacity increases as market demand expands.

- Driving Innovation and Sustainability: A modern extrusion line is a platform for innovation. It enables manufacturers to experiment with new material composites, integrate recycled content, a key feature of WPC and develop products with enhanced functionalities. These can include UV-resistant coatings for outdoor use, antimicrobial finishes for healthcare settings, and advanced fire-retardant properties. By facilitating the production of sustainable, durable products, Kriimpas technology helps builders meet increasingly stringent environmental regulations and consumer preferences.

- Precision & Consistency: With advanced PLC control systems, precision calibration units, and stable thermal management, our lines ensure every board meets exact specifications for thickness, width, and density. This results in a consistently high-quality product, batch after batch.

- Material & Energy Efficiency: The conical twin-screw design is inherently energy-efficient, requiring less torque and power. Furthermore, the technology is compatible with high ratios of recycled content, allowing you to reduce raw material costs and support circular economy initiatives.

- Robust After-Sales Support: Our partnership doesn’t end at delivery. Kriimpas provides complete assistance, including machine installation, commissioning, operator training, and reliable technical support to ensure your line operates at peak performance.

Types of PVC WPC Panel Board

1. Rigid PVC Board Extrusion Lines

- These lines produce solid (non-foamed) PVC boards — typically smooth and dense boards suitable for partitions, wall panels, decorative sheets, and general building materials.

2. PVC WPC Foam Board Extrusion Lines

- These lines produce foam or light‑weight boards, using foaming agents or controlled expansion during extrusion to create a cellular structure inside.

3. WPC Wood‑Plastic Composite Panel Board Extrusion Lines

- These lines manufacture composite boards combining plastic with wood fibres or wood flour. The result is a material that offers a wood-like appearance and plastic-like strength/durability.

4. Specialised Profile Panel Extrusion Lines

- These are extrusion lines designed to produce panels with particular shapes or use-cases for example, wall‑panel lines, ceiling-panel lines, door‑panel lines, fluted or louvred wall panels, cladding panels, etc.

4. Profile Co‑extrusion Lines

- These are more advanced extrusion lines capable of producing custom-shaped profiles, panels, or boards with multiple layers: e.g., co‑extrusion of WPC inside high‑quality WPC outside, or PVC‑WPC hybrids.

Conclusion

Innovation, sustainability, and performance are key to the future of interior finishes and building materials. One of the most adaptable and useful options available today is PVC WPC panel boards, which are produced utilising a sturdy extrusion process. In addition to being affordable and scalable for mass manufacturing, they combine the strength, endurance, and workability of wood with the moisture resistance, low maintenance, and longevity of plastics. We are the best PVC WPC Panel Board Extrusion Line in Gujarat.

Working with Kriimpas India Pvt. Ltd. is a wise decision for manufacturers wishing to enter this exciting market or increase their manufacturing capacity. We assist clients in creating a production line that consistently produces high-quality products and positions them for the expanding demand in the construction, furniture, and décor markets thanks to our technical know-how, capacity for customisation, quality-driven manufacturing approach, and end-to-end support.