PP PS Environmental Sheet Extrusion Line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

In today’s ever-changing manufacturing environment, sustainability is expected rather than only a fad. Green solutions are being adopted by industries all around the world due to long-term cost savings, consumer preferences, and environmental requirements. The PP PS Environmental Sheet Extrusion Line, a cutting-edge technology that is revolutionising the production of polypropylene (PP) and polystyrene (PS) sheets, is one such innovation in sustainable manufacturing. We at Kriimpas India Pvt. Ltd. are proud to provide cutting-edge extrusion technologies that promote environmental responsibility while simultaneously maximising production. For contemporary sheet production, our PP PS Environmental Sheet Extrusion Line is the ideal fusion of performance, dependability, and sustainability. We are the best PP PS Environmental Sheet Extrusion Line Manufacturer.

What is a PP PS Environmental Sheet Extrusion Line

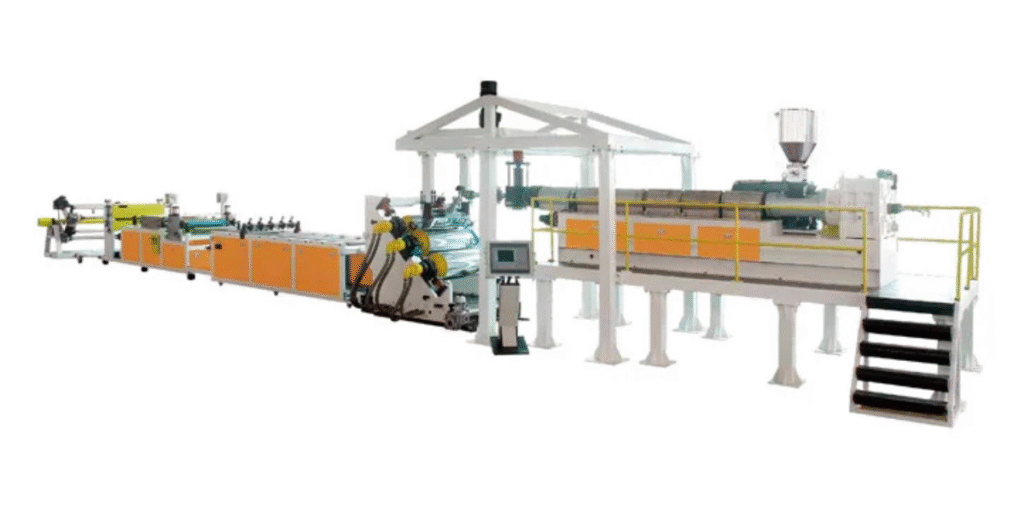

An integrated production system called a PP PS Environmental Sheet Extrusion Line uses polystyrene (PS) and polypropylene (PP) resins to create high-quality sheets. Packaging, displays, construction, automotive, and signs are just a few of the industries that use these sheets. The environmental sheet extrusion line integrates cutting-edge energy-saving features, optimal material use, and emissions-reducing processes, in contrast to conventional extrusion systems. For firms that wish to maintain optimal performance while adhering to environmental guidelines, this makes it an excellent option. We are the best PP PS Environmental Sheet Extrusion Line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Unmatched Efficiency & Cost-Effectiveness Modern extrusion technology is designed for high-speed, high-volume production with minimal downtime. Advanced control systems drastically reduce material waste and energy consumption—some energy-efficient designs report savings of up to compared to older systems. This optimisation translates directly to a lower cost per unit and a stronger bottom line.

- Operational Flexibility & Future-Proofing: A high-performance line offers remarkable adaptability. It can handle a wide range of material formulations, including blends of virgin and recycled resin. This flexibility allows manufacturers to quickly respond to market trends, fulfil custom client requests, and transition to newer, more sustainable materials as they emerge, ensuring the business remains resilient and relevant.

- A Commitment to Environmental Responsibility. This is the cornerstone of the “Environmental” line. It enables manufacturers to actively reduce their ecological footprint by processing recycled plastics, minimising energy and water use, and reducing production scrap. In an era where consumers and regulators demand greener practices, this capability is no longer optional—it’s a critical component of brand integrity and long-term viability.

- Deep Industry Expertise and Customisation: Kriimpas understands that every production goal is unique. The company specialises in providing top-notch extrusion lines tailored to specific needs. Their team oversees the entire process—from initial design and assembly to rigorous testing—ensuring the final solution is not just a standard machine, but a customised system aligned with your production targets, material mix, and budget.

- Commitment to Quality and Innovation: As a company that serves demanding sectors like packaging, automotive, and biomedical industries, Kriimpas adheres to stringent manufacturing standards. Their machinery is engineered using the latest technology and premium materials to deliver exceptional, reliable performance on the production floor. This focus on innovation ensures your investment is future-proof.

- Comprehensive Support Model: The relationship with Kriimpas begins long before installation and continues indefinitely. The company’s dedicated support framework includes pre-sale consulting to define the optimal solution, on-site training for your operators, and lifetime maintenance support. This end-to-end service model minimises downtime, accelerates your time-to-market, and maximises the long-term return on your investment.

- Engineering Excellence Custom-Tailored Solutions Kriimpas operates on the principle that no two manufacturing challenges are identical. Their team of highly qualified engineers specialises in designing and building extrusion lines tailored to your specific needs. Whether your priority is a particular output capacity, a unique sheet dimension, or the ability to process specialised polymer blends, they collaborate with you to create a system that delivers optimal performance and efficiency.

- Enhanced Production Efficiency and Reduced Waste: Features like automated precision cutting and programmable length control minimise off-spec material. The stable extrusion process itself, governed by advanced controls, leads to less start-up waste and higher overall equipment effectiveness.

- Energy Efficiency and Cost-Effectiveness: Modern extruders are designed with energy-efficient drives and heating systems that significantly reduce power consumption per kilogram of output. Lower operational costs, combined with reduced material waste, contribute directly to a healthier bottom line.

- Automation and Ease of Operation: The line is designed for smooth operation. The user-friendly control interface allows operators to manage the entire process, from recipe recall to fault diagnostics, making it easier to run and maintain consistent production.

Applications of PP PS Environmental Sheet Extrusion Line

1. Food Packaging Industry

- PP and PS sheets produced through environmental sheet extrusion lines are extensively used in the food packaging sector. These sheets are suitable for manufacturing disposable food containers, trays, cups, lids, and packaging boxes. Due to their food-grade quality, hygiene standards, moisture resistance, and lightweight nature, they are ideal for packaging fresh foods, dairy products, fruits, vegetables, and takeaway meals. The environmental extrusion line ensures reduced material waste and improved sustainability.

2. Disposable Products Manufacturing

- The extrusion line is widely applied in producing sheets for thermoformed disposable items such as plates, bowls, cups, spoons, and containers. PP and PS sheets offer excellent rigidity and durability while remaining cost-effective. The environmental extrusion process supports recyclable and eco-conscious production, meeting the growing demand for sustainable disposable products.

3. Pharmaceutical Packaging

- PP and PS sheets are commonly used in pharmaceutical packaging, including blister packs, medicine trays, and protective covers. These sheets provide excellent chemical resistance, clarity, and safety, helping to maintain product integrity and hygiene. The precision control of the extrusion line ensures uniform thickness, which is essential for pharmaceutical applications.

4. Stationery and Office Supplies

- In the stationery industry, PP and PS sheets are used to manufacture folders, files, document covers, notebook covers, and transparent sheets. Their smooth surface, flexibility, and durability make them ideal for everyday office and school use. The environmental extrusion line ensures high productivity with minimal energy consumption.

5. Advertising and Printing Applications

- PP and PS sheets are widely used in printing, signage, and advertising boards. These sheets provide excellent printability and surface finish, making them suitable for posters, display boards, branding materials, and promotional panels. The extrusion line supports consistent quality for large-scale printing applications.

6. Medical and Healthcare Products

- The medical industry utilises PP and PS sheets for manufacturing medical trays, diagnostic kits, disposable medical packaging, and protective covers. These materials are preferred due to their non-toxic nature, sterilisation compatibility, and high strength, ensuring safety and reliability in healthcare environments.

7. Industrial Packaging and Protection

- PP and PS sheets are used in industrial packaging solutions such as separators, protective sheets, liners, and cushioning materials. Their impact resistance and lightweight structure make them ideal for protecting machinery parts, electronics, and fragile components during storage and transportation.

8. Household and Consumer Goods

- Many household products, such as storage boxes, organisers, kitchenware packaging, and consumer product trays, are manufactured using PP and PS sheets. The extrusion line enables the production of visually appealing, durable, and cost-effective sheets that meet modern consumer expectations.

9. Recycling and Sustainable Manufacturing

- The PP PS Environmental Sheet Extrusion Line supports the use of recycled materials and promotes sustainable plastic processing. It reduces raw material wastage, energy consumption, and environmental impact, making it an ideal solution for manufacturers focused on eco-friendly production and circular economy practices.

Table Specifications of PP PS Environmental Sheet Extrusion Line

| Parameter | Specification |

|---|---|

| Material | PP PS Environmental Sheet Extrusion Line |

| Screw Diameter | 90–150 mm |

| L/D Ratio | 30:1 / 33:1 / 36:1 |

| Production Speed | 10–60 m/min |

| Sheet Width | 500–2000 mm |

| Sheet Thickness Range | 0.5–5 mm |

| Output Capacity | 200–1500 kg/hr |

| Drive Motor Power | 55–200 kW |

| Temperature Zones | 6–8 zones |

| Automatic Thickness Control System | Included |

| Cooling System | Water or Air Cooling |

| Control Panel | PLC Touch Screen |

| Material Compatibility | PP / PS / Recycled Material |

| Power Supply | 380V / 440V / Customized |

| Optional Accessories | Edge Trimming Unit, Winding System, Stackers |

Benefits of PP PS Environmental Sheet Extrusion Line

- Superior Product Quality and Consistency: The integration of a digital control system allows for real-time monitoring and precise adjustment of temperature, pressure, and speed. This ensures every meter of sheet produced has uniform thickness, excellent optical clarity, and a flawless surface finish, drastically reducing reject rates.

- Enhanced Production Efficiency and Reduced Waste: Features like automated precision cutting and programmable length control minimise off-spec material. The stable extrusion process itself, governed by advanced controls, leads to less start-up waste and higher overall equipment effectiveness.

- Energy Efficiency and Cost-Effectiveness: Modern extruders are designed with energy-efficient drives and heating systems that significantly reduce power consumption per kilogram of output. Lower operational costs, combined with reduced material waste, contribute directly to a healthier bottom line.

- Automation and Ease of Operation: The line is designed for smooth operation. The user-friendly control interface allows operators to manage the entire process, from recipe recall to fault diagnostics, making it easier to run and maintain consistent production.

- Comprehensive Support Ecosystem: From initial installation and operator training through ongoing maintenance and technical support, Kriimpas ensures customers maximise the value of their investment throughout the equipment lifecycle.

- Continuous Innovation: By staying at the forefront of extrusion technology and sustainable manufacturing practices, Kriimpas helps clients future-proof their operations against changing market demands and regulatory requirements.

- Quality Assurance: Using premium components and rigorous testing protocols, Kriimpas delivers equipment that meets stringent performance and durability standards, minimising unplanned downtime and maintenance costs.

- Exceptional Physical Properties: These materials deliver robust performance. PS sheets offer a high degree of transparency, ideal for packaging where product visibility is key. PP sheets, on the other hand, provide notable impact resistance and can maintain stable physical and chemical properties in high-temperature environments, making them suitable for protective packaging and applications requiring heat treatment.

- Versatility and Cost-Effectiveness: Both PP and PS are known for their easy processing and good plasticity, allowing them to be moulded into various shapes and sizes to meet diverse needs. Furthermore, the raw material costs for PP and PS are competitive, and the mature, efficient production process enables cost-effective mass production, delivering strong value.

- Extruder & Precision Components: The process begins with the extruder, which melts and homogenises the polymer resin. Critical attachments like a screen changer filter impurities, while a melt pump ensures a consistent, pulseless flow of material to the die, which is crucial for uniform sheet thickness.

- Forming & Cooling Systems: The molten plastic is shaped by a specialised T-die and then passes through a three-roll calender. This unit is vital for precisely setting the sheet’s final thickness and surface finish. The sheet is then solidified on a cooling conveyor.

- Finishing & Winding: After cooling, the sheet’s edges are trimmed by a dedicated unit. The finished product is finally wound into large rolls by a winder machine, ready for the next steps in manufacturing, such as thermoforming.

Types of PP PS Environmental Sheet Extrusion Line

1. Single Screw Extrusion Line

Best For: Standard PP/PS sheets with consistent thickness

Features:

- Simplified design and operation

- Lower maintenance costs

- Excellent for general sheet manufacturing

2. Twin Screw Extrusion Line

Best For: High output, complex materials, recycled content

Features:

- Enhanced mixing and melt homogenization

- Better handling of additives and reclaimed plastics

- Higher throughput

3. Calendar Sheet Extrusion Line

Best For: High-quality sheet surfaces and dimensional control

Features:

- Precision calendering rolls

- Excellent surface finish

- Tight thickness tolerances

4. Co-Extrusion Sheet Line

Best For: Multi-layer environmental sheets

Features:

- Simultaneous extrusion of multiple polymer layers

- Customised layer performance (strength, barrier properties)

- Tailored sheet characteristics

Conclusion

The PP PS Environmental Sheet Extrusion Line represents a significant leap forward in sustainable manufacturing. By offering an efficient, reliable, and eco‑friendly solution for producing high‑quality plastic sheets, Kriimpas India Pvt. Ltd. empowers manufacturers to reduce environmental impact while improving operational performance. Whether you are in packaging, construction, automotive, or industrial fabrication, investing in advanced extrusion technology today can unlock long‑term benefits for your business and the planet. We are the best PP PS Environmental Sheet Extrusion Line in Gujarat.

Investing in a PP PS Environmental Sheet Extrusion Line is more than just a technological advancement; it’s a calculated step toward sustainability, quality, and profitability as industries throughout the world strive toward greener solutions. By guaranteeing that Indian businesses have access to cutting-edge, ecologically friendly extrusion technology, Kriimpas India Pvt. Ltd. keeps setting industry standards.