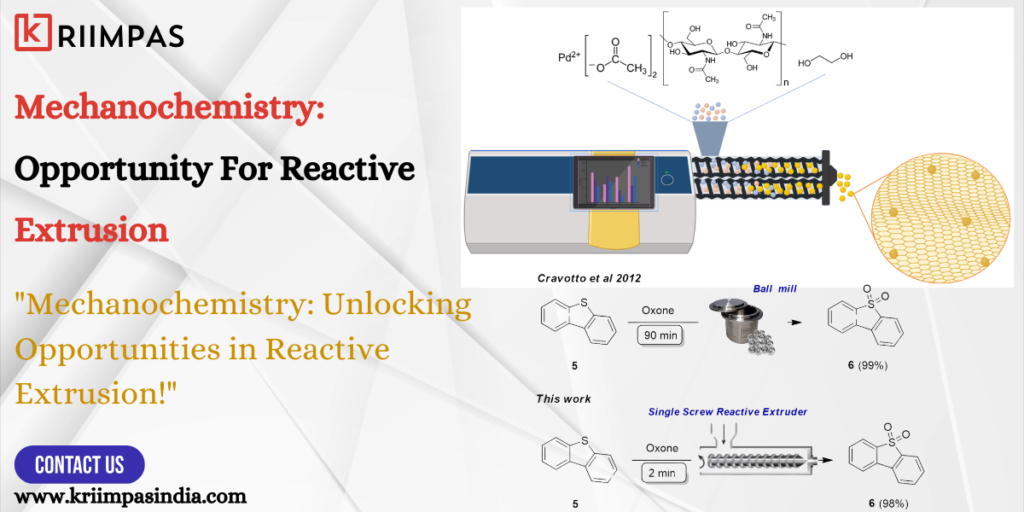

Mechanochemistry: Opportunity For Reactive Extrusion

Table of Contents

Introduction

Our range of offerings includes Processing Machinery for different Materials, Motion Based Solutions, Automation & Technological Solutions, Additive & Hybrid Manufacturing Solutions, and a wide array of spares and parts. Each product is meticulously engineered using the latest technology and premium quality raw materials sourced from reliable vendors. Our commitment to excellence ensures that our products meet stringent industry standards, delivering exceptional quality and performance. We are the best mechanochemistry: opportunity supplier.

Innovation is the foundation of advancement in the dynamic fields of materials science and chemical processing. We’re seeing a paradigm change as traditional, frequently resource-intensive approaches give way to more effective and sustainable ones. When combined with reactive extrusion, mechanochemistry is one such promising approach that creates a plethora of opportunities. We at Kriimpas India Pvt. Ltd. are committed to using these innovative technologies to propel progress across a range of sectors.

What is Mechanochemistry?

Imagine triggering chemical reactions not with heat or solvents, but with the sheer force of grinding, milling, or shearing. That’s the essence of mechanochemistry. It involves using mechanical energy to induce chemical transformations in solid-state materials. This approach offers several advantages over traditional solution-based or thermal methods: We are the best mechanochmistry: opportunity manufacturer.

Applications Kriimpas India Pvt. Ltd.

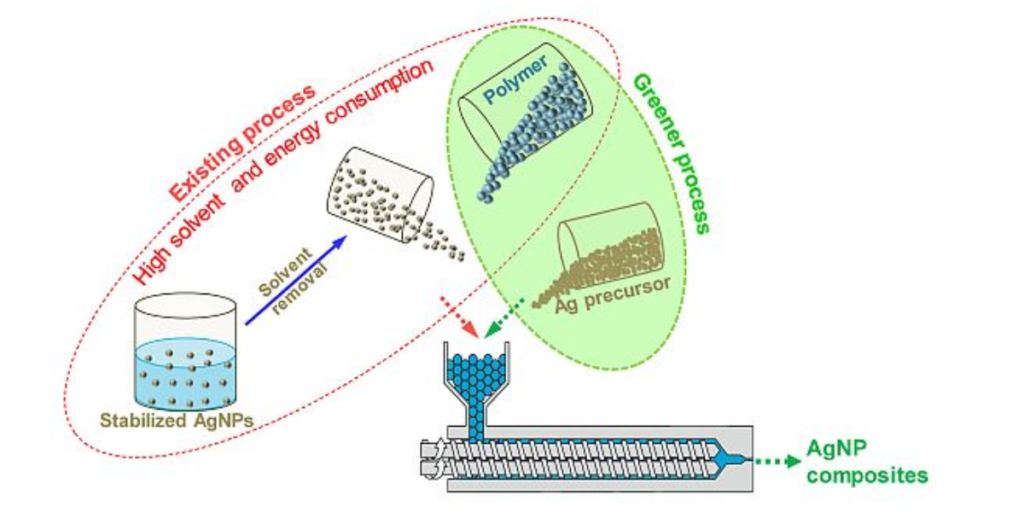

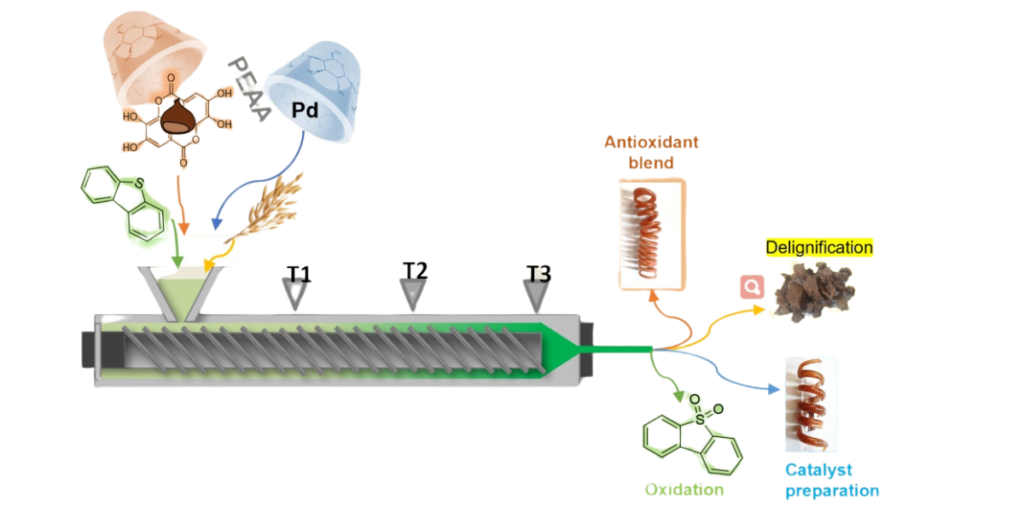

- Reactive extrusion and mechanochemical modification are two ways Kriimpas India Pvt. Ltd. can assist polymer manufacturers in creating new and enhanced polymer materials. This covers the development of sustainable biopolymers, functionalized polymers, and high-performance composites.

- Pharmaceutical Processing: By using amorphous solid dispersions, we can help pharmaceutical businesses improve medication bioavailability and create solvent-free methods for API synthesis and formulation.

- Advanced Materials Synthesis: Through mechanochemical synthesis and processing, Kriimpas India Pvt. Ltd. can aid in the development of advanced materials, including metal-matrix composites, ceramics, and nanomaterials.

- Chemical Synthesis and Catalysis: By employing solvent-free reactions and mechanochemically activated catalysts, we can assist chemical industries in creating environmentally friendly and effective chemical processes.

- Food Processing Innovation: Using mechanochemical techniques, Kriimpas India Pvt. Ltd. assists food industries in developing innovative food components, encapsulated food additives, and textures.

- Waste Upcycling: We can help create procedures that turn waste streams into valuable materials by using reactive extrusion and mechanochemistry. This includes turning biomass into useful chemicals and reusing polymers.

- Research and Development: To investigate the use of reactive extrusion and mechanochemistry in novel and developing fields, we provide R&D services.

Why Choose Kriimpas India Pvt. Ltd.?

- Knowledge and Experience: Our group of highly qualified scientists and engineers has a wealth of knowledge about materials processing and extrusion technologies. We understand the fundamentals of mechanochemistry and how it applies to reactive extrusion.

- Tailored Solutions: We are aware that each client has particular needs. We collaborate closely with our clients to provide solutions that are tailored to their individual requirements.

- Modern Equipment: We provide a large selection of modern extruders and related equipment, such as pelletizers, twin-screw extruders, and single-screw extruders. High performance, dependability, and user-friendliness are key design features of our equipment.

- All-inclusive Services: We offer a wide range of services, such as technical assistance, training, commissioning, installation, and equipment supply. We are dedicated to making sure our clients succeed.

- Collaboration and Innovation: We are dedicated to both collaboration and innovation. We collaborate closely with our clients to create fresh, creative answers to their problems. In order to progress the field of mechanochemical reactive extrusion, we are also actively engaged in research and development.

- Emphasis on Sustainability: We are dedicated to creating environmentally friendly solutions that are sustainable. We are particularly interested in mechanochemical reactive extrusion since it provides a more environmentally friendly option to conventional chemical processes.

- Customer-focused strategy: Our clients come first at Kriimpas India Pvt. Ltd. Our commitment is to deliver outstanding customer service and support. Our goal is to establish enduring bonds of respect and trust with our clients.

Benefits of Partnering with Kriimpas India Pvt. Ltd.

- Knowledge and Experience: Kriimpas India Pvt. Ltd. has a group of highly qualified engineers and technicians with a wealth of knowledge in mechanochemical applications and extrusion technology.

- Tailored Solutions: We recognize that each application is distinct. We offer specialized solutions made to meet your unique needs, guaranteeing peak effectiveness and performance.

- Modern Equipment: For mechanochemical reactive extrusion, we provide a large selection of modern extruders and related equipment.

- Technical Support and Training: To guarantee seamless operation and optimal productivity, we offer thorough technical support, which includes installation, commissioning, and training.

- Research & Development: To stay on the cutting edge of technology, we make significant investments in research and development as part of our dedication to ongoing innovation.

- Quality and Reliability: Our equipment is dependable, long-lasting, and consistently performs because we uphold the highest quality standards.

Types Kriimpas India Pvt. Ltd.

- Twin Screw Extruders: We provide a range of twin screw extruders that are tailored for applications involving reactive extrusion. Effective mechanochemical reactions are made possible by these extruders’ superior mixing and shearing capabilities.

- Single Screw Extruders: For some reactive extrusion applications requiring less vigorous mixing, we also provide single screw extruders.

- Compounding Extruders: Our compounding extruders are made to add additives and fillers to polymer matrices, which makes it easier to create high-performance composites.

- To transform extruded materials into granules or pellets for additional processing, we offer granulators and pelletizers.

- loading Systems: To guarantee precise and reliable reactant loading into the extruder, we provide a variety of feeding systems.

- Die Heads and Downstream Equipment: To form and process the extruded materials, we provide a range of die heads and downstream equipment.

- Laboratory Extruders: We provide laboratory-scale extruders for research and development.

- Maintenance and Spare Parts: To guarantee the best possible operation of our extrusion systems, Kriimpas India Pvt. Ltd. also offers maintenance services and spare parts.

- Formulation development consulting: Assisting clients in creating formulations for particular uses.

- Process optimization consulting: Assisting clients in streamlining their operations to maximize efficiency.

- Services for Material Characterization: Our laboratories provide services for material characterization.

Key Advantages of Mechanochemistry

- Sustainability: Mechanochemical reactions minimize waste and their negative effects on the environment by frequently eliminating or drastically reducing the requirement for solvents.

- Energy Efficiency: Mechanochemistry can significantly lower energy usage by avoiding the requirement for high temperatures.

- Novel Materials: It makes it feasible to synthesize materials with distinct structures and characteristics that are hard or impossible to achieve using conventional techniques.

- Enhanced Reaction Rates: By expanding the area of contact between reactants and producing extremely reactive surfaces, mechanical forces can quicken reactions.

- Controlled Synthesis: By providing exact control over reaction conditions, mechanochemistry enables the customization of material properties.

Conclusion

Reactive extrusion and mechanochemistry are a potent combination with enormous potential for the advancement of materials research and industry. We can develop innovative materials with specific qualities, lessen our influence on the environment, and spur innovation in a variety of industries by utilizing mechanical forces.Kriimpas India Pvt. Ltd. is dedicated to leading this fascinating industry by offering our clients state-of-the-art solutions and knowledge to help them realize the full potential of reactive extrusion and mechanochemistry. These technologies, in our opinion, will be essential in forming a more inventive and sustainable future. We are the best mechanochemistry: opportunity provider.