Doritos Tortilla Chips Extrusion Cooking line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Ever wonder what ingredients go into creating a tasty, crunchy Doritos tortilla chip Its a journey that begins with a plain maize kernel and concludes with that universally beloved crunch. While the traditional way of making tortilla chips involves heating, steeping, and crushing maize into a dough known as masa many contemporary snack food giants have resorted to an inventive and incredibly effective technique called extrusion cooking. Millions of bags of your favorite triangular snack are produced thanks to this technique, which is a miracle of food science and engineering. Explore the intriguing world of the Doritos Tortilla Chips Extrusion Cooking range by taking a closer look. We are the best Doritos Tortilla Chips Extrusion Cooking line Manufacturer.

What is Doritos Tortilla Chips Extrusion Cooking line

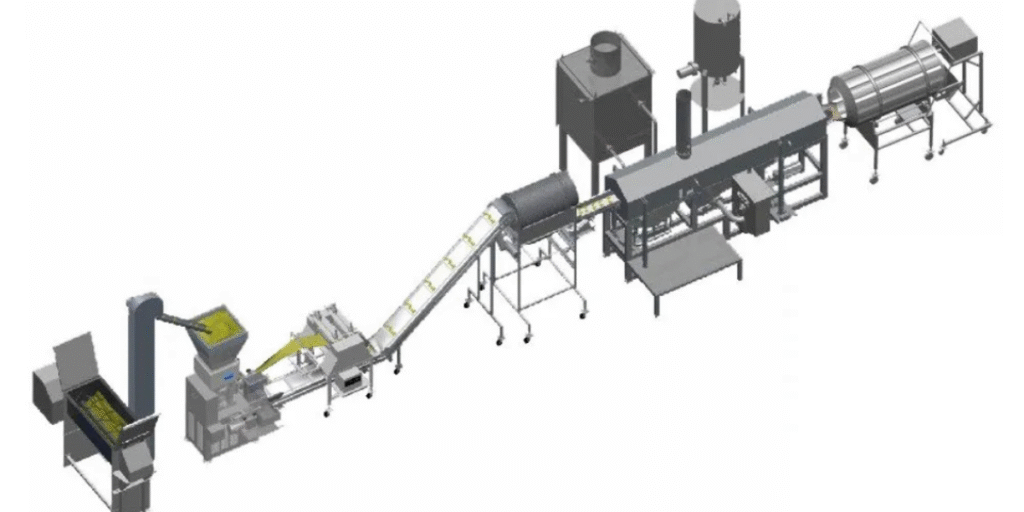

Consider an extruder to be a huge, sophisticated kitchen appliance. This piece of machinery integrates shape, forming, cooking, and mixing into a single, continuous process. The process begins with a meticulously crafted mixture of raw ingredients, mostly corn flour, for a product like Doritos.The extruder is fed this flour, water, and additional components. A revolving screw or twin screws does its magic inside. The components are mixed as the screw rotates, and the pressure and friction produce a lot of heat. The maize flour is cooked by the pressure and heat, becoming a soft hot dough. We are the best Doritos Tortilla Chips Extrusion Cooking line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Unmatched Innovation and Expertise: Kriimpas India is an innovator as well as a manufacturer. By integrating the most recent developments in automation and control systems into their extrusion lines, they maintain their position as leaders in food processing technology. This indicates that their machinery is more dependable, efficient, and able to generate a higher-quality end product. For instance, their twin-screw extruders are painstakingly designed to provide exact control over the cooking process, guaranteeing that your treats will always have the ideal texture and quality.

- Customized, Complete Solutions: Kriimpas is aware that every company has different requirements. They don’t provide a universal strategy. Rather, their team of highly qualified engineers collaborates closely with you to develop and construct a Doritos Tortilla Chips Extrusion Cooking line that meets your unique needs, from output capacity and automation levels to material composition and required product dimensions. They offer a comprehensive, one-stop service that eliminates all worries throughout the process, from initial design to installation and training.

- Quality and Durability: Production lines need significant capital, and downtime can be expensive. Kriimpas India is dedicated to providing consistently high-quality services. To guarantee that their equipment is strong, long-lasting, and constructed to resist the demands of continuous, high-volume manufacturing, they only utilize premium-grade materials and components from reliable vendors. By emphasizing durable equipment, you may reduce maintenance requirements and increase your return on investment.

- Superior Value at Competitive Prices: Kriimpas India is a domestic business with an international outlook. They provide affordable solutions without sacrificing effectiveness or caliber. Over time, their dependable equipment and effective designs lower operational costs, offering you a significant competitive advantage in the marketplace.

- Extensive After-Sales Assistance: The partnership continues long after the transaction. Installation, employee training, and continuing maintenance support are all included in Kriimpas India’s comprehensive after-sales service package. Their committed staff of experts is always ready to assist, guaranteeing that your production line continues to operate smoothly and effectively for many years to come.

- Devoted After-Sales Support: We continue to be committed to our customers after the sale. We offer comprehensive post-purchase assistance, which includes maintenance, training, and installation. We make sure your staff has everything they need to run the equipment effectively, reducing downtime and increasing output.

- Reliability and Quality: At Kriimpas India, we place a high premium on quality. High-quality, long-lasting materials are used in the construction of our machines to guarantee enduring performance. In order to provide dependable and effective equipment that will be a significant benefit to your company for many years to come, we strictly adhere to quality control requirements.

- Cost-effective and Energy-Efficient: Our extrusion lines are made to use as little energy as possible while producing as much as possible. Your company will become more competitive in the market as a result of reduced operating expenses and an improved return on investment.

Applications of Doritos Tortilla Chips Extrusion Cooking line

1. Large-scale snack manufacturers

- Large snack companies use high-capacity extrusion lines to produce millions of bags per month. They require automation, quick changeover between flavours, and integrated quality controls for consistent shelf life and taste.

2. Co-packers and private label producers

- Co-packing businesses buy versatile extrusion lines so they can manufacture several client brands on the same equipment. The line’s flexibility for frying or baking and quick recipe changes is essential.

3. Regional & local snack brands

- Smaller companies use compact extrusion lines to launch new Doritos-style flavors for local taste preferences — from spicy masala to cheese variants. Local producers often choose lines with lower initial investment but scalable capacity.

4. R&D and product development labs

- Food technologists and R&D teams use pilot extrusion lines to test new shapes, textures, and seasonings before scaling up to full production.

5. Specialty & healthier snack producers

- Brands that focus on baked, low-fat, or whole-grain snacks use extrusion lines with baking options to create health-oriented tortilla chips without compromising crunch.

6. Foodservice and institutional kitchens

- Large institutions that need bulk snack supplies can install mid-size lines to make consistent, on-site products for events or cafeterias. In each application, manufacturers benefit from customizing the line: die shapes, extruder screw design, fryer length, seasoning system type, and automation level.

Table Specifications of Doritos Tortilla Chips Extrusion Cooking line

| Parameter | Typical Specification |

|---|---|

| Material | Doritos Tortilla Chips Extrusion Cooking line |

| Extruder Type | Twin-screw, co-rotating, modular barrel |

| Screw Diameter | 62–93 mm (model-dependent) |

| L/D Ratio | 28–40:1 (configurable) |

| Main Drive Power | 55–160 kW (inverter-controlled) |

| Heating Zones | 6–10 independently controlled zones |

| Feed System | Loss-in-weight feeders for flour and water |

| Die & Cutter | Triangle die set, rotary or guillotine cutter (speed adjustable) |

| Sheeter Option | Sheeting/lamination module for layered textures (optional) |

| Pre-Dryer/Oven | 60–120 °C, 2–6 min residence (optional) |

| Continuous Fryer | 170–190 °C, 30–90 s; oil level auto-control |

| Oil Filtration | Multistage filtration + oil turnover monitoring |

| Seasoning System | Slurry/oil spray + powder dosing in tumbler |

| Cooling | Ambient/forced-air cooling conveyor |

| Construction | SS304/SS316 contact parts; food-grade belts |

| Controls | PLC + 7–12″ HMI, recipe library, data logging |

| Utilities – Power | 120–350 kW (line-dependent) |

| Utilities – Air | 6–8 bar, 200–600 L/min (actuators & CIP) |

| Utilities – Water | For cleaning/CIP and slurry make-up |

| Footprint | ~35–60 m line length (layout specific) |

| Safety | CE-style guards, interlocks, E-stops, lockout points |

| Options | Flavor slurry skid, dust collection, CIP, nitrogen flush pack, inline QA sensors |

Benefits of Doritos Tortilla Chips Extrusion Cooking line

- Sturdy Quality and Durability: We are committed to creating long-lasting machines. Our systems are strong and long-lasting because they are made using premium materials and parts. Our quality assurance team thoroughly tests each stage of our production process to ensure peak performance for many years to come.

- Cutting-Edge Technology: To guarantee optimal efficiency, accuracy, and dependability, our extrusion lines are outfitted with the newest technology. This includes cutting-edge control technologies that increase production, reduce downtime, and streamline the entire process.

- Tailored Solutions: We are aware that every company is different. We provide a range of adjustable extrusion lines to suit various capacities and product kinds, regardless of your size from small-scale startups to major industrial players. Together, you and our skilled engineers will create and execute a solution that precisely matches your production objectives and workshop configuration.

- Sturdy Quality and Durability: We are committed to creating long-lasting machines. Our systems are strong and long-lasting because they are made using premium materials and parts. Our quality assurance team thoroughly tests each stage of our production process to ensure peak performance for many years to come.

- Comprehensive Support and Expertise: Our team of professionals has a wealth of extrusion technology knowledge. We offer expert assistance from the first consultation to the last installation and beyond. As your committed partner, we provide technical support, after-sales care, and insights to guarantee the flawless operation of your production line.

- Scalability for Growth: Our solutions are built to grow with your business. Our modular solutions make it simple to scale up production as demand for your goods rises, enabling a smooth transition to larger capacities without requiring a total redesign.

- Sustainable and Effective: Our extrusion lines are designed to be extremely energy-efficient, which lowers your operating expenses and damages the environment. A more sustainable business strategy is also facilitated by the process’s low waste creation.

Types of Doritos Tortilla Chips Extrusion Cooking line

Single-screw extruder lines

- Simple and cost-effective. Good for modest production and straightforward formulations. They produce consistent extrusion but limited in handling complex recipes compared to twin-screw.

Twin-screw extruder lines

- More flexible with better control over mixing and moisture. Ideal for bigger plants or when using multi-ingredient formulations cheese powders, flavor matrices, or inclusions Twin-screw extruders handle viscous dough and temperature-sensitive ingredients better.

Continuous frying lines

- Designed for high-capacity production with consistent oil temperature control and effective oil filtration systems.

Continuous baking lines

- An alternative to frying for health-focused products; uses controlled airflow and temperature to achieve crispness.

Integrated seasoning and coating systems

- These include centrifugal seasoning drums and spray systems for uniform flavor application — essential for Doritos-style strong flavors.

Automated packaging lines

- Vertical form-fill-seal machines and weighers to ensure accurate weights, faster throughput, and attractive bag presentation.

Conclusion

Extrusion cooking demonstrates the inventiveness of contemporary food science and is more than just a technical procedure. It has completely changed how we manufacture a variety of goods, making them more palatable, reliable, and accessible. Think about the amazing journey that small triangle chip took a journey made possible by the precise and potent technology of an extrusion frying line the next time you open a bag of Doritos.

Keep Kriimpas India Pvt. Ltd. in mind if you want to upgrade your current facility or get into the snack food production business. We are committed to giving you the tools and know-how you need to achieve the highest possible level of flavor, texture, and success. Get in touch with us right now to find out how our cutting-edge extrusion solutions may assist you in developing the upcoming snack market sensation.