Corn Flakes Cereal Extrusion Cooking line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

You’ve probably seen the bowl of corn flakes that greets you each day, but have you ever wondered how those flawless, golden flakes are created? Extrusion cooking is the transformational process at the heart of the intriguing journey from a modest corn kernel to a crispy, delectable breakfast cereal. The production of reliable, superior, and nutrient-dense grains has been made possible by this advanced technology, which is more than just a straightforward process.We’ll go further into the realm of corn flakes production in this extensive guide, examining the crucial function of extrusion cooking. We are the best Corn Flakes Cereal Extrusion Cooking line Manufacturer.

From the raw materials to the finished packaged product, we will take you through every step of the process and show you why this technology is revolutionizing the food manufacturing industry globally. We’ll also highlight Kriimpas India Pvt. Ltd., a business that is leading the way in supplying this innovative technology to the Indian market and beyond.

Why of Corn Flakes Cereal Extrusion Cooking line

It’s critical to comprehend the historical production process for corn flakes before delving into extrusion. There were several steps in the traditional method, including a great deal of heating, cooling, and tempering. Large pressure cookers would be used to cook corn grits in a mixture of salt, sugar, and malt. To guarantee that the grits were cooked to the proper consistency, this procedure took a long time and needed close supervision.

The grits needed to be cooled after cooking and then “tempered,” which is a procedure that involves letting them sit for a while to let the moisture content to balance out. They could only be rolled into flakes after which they were roasted to get their renowned crunch. We are the best Corn Flakes Cereal Extrusion Cooking line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Leading Technology and Knowledge: Kriimpas India Pvt. Ltd. is well known for providing state-of-the-art equipment. The newest European technology is used in the design of their corn flakes extrusion lines, guaranteeing excellent product quality, low power consumption, and high efficiency. Their extensive knowledge of the extrusion process enables them to create lines that are both sturdy and tailored to yield the highest-quality corn flakes.

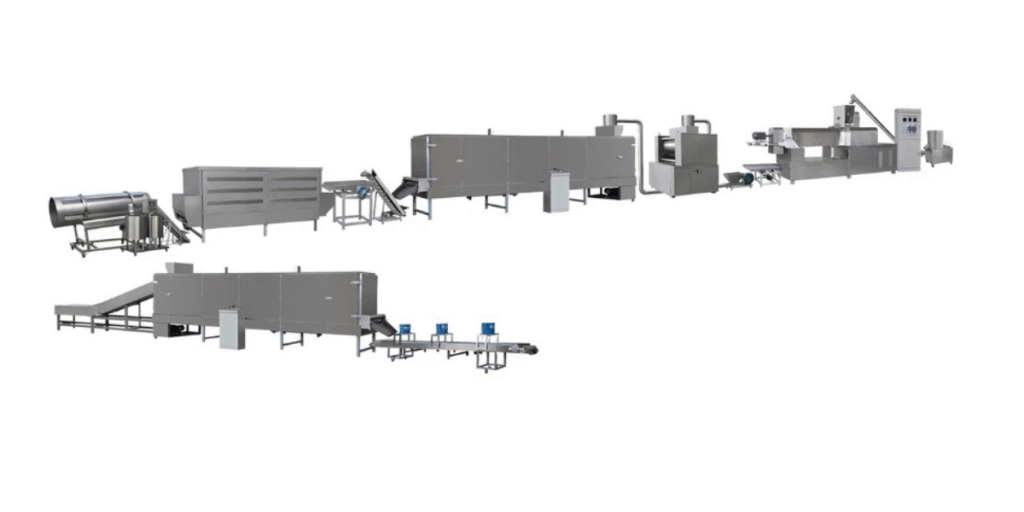

- Full Turnkey Solutions: They provide a comprehensive, end-to-end solution. This implies that they offer the complete production line, including the mixer, extruder, flaking machine, dryer, and packing apparatus, rather than just selling you the extruder. This smooth integration minimizes production problems and maximizes output by guaranteeing that every part functions in perfect harmony.

- Sturdy and Long-Lasting Construction: Kriimpas India’s equipment is made to last. Food-grade stainless steel, which is resistant to corrosion and wear, is used to make all components that come into contact with food. This provides a long-term return on your investment, maintains hygiene, and increases the machinery’s longevity.

- High Production Capacity and Efficiency: Kriimpas India’s machinery is built to produce large quantities. Their lines require very little manual involvement because they are completely automated. You can fulfill the rising demand for your product thanks to this automation, which also lowers labor costs and boosts production efficiency. They provide a range of capacities to accommodate companies of all sizes, from start-ups to major corporations.

- Simple to Use and Maintain: Their systems are easy to use even with their sophisticated technology. The machines’ modular architecture makes cleaning and maintenance easier, and the Programmable Logic Controller control system makes operation simple. Their extruders self-cleaning feature is a significant benefit that saves time and work.

- Outstanding Customer Service: Kriimpas India Pvt. Ltd. is committed to establishing enduring bonds with its customers. From helping with the initial plant planning to offering installation, training, and after-sales servicing, they provide all-encompassing support. To ensure your production works well, their team of professionals is always accessible to answer your queries and assist you in troubleshooting any issues.

- Proven Track Record: Kriimpas India Pvt. Ltd. has a strong industry presence and a history of happy clients. Their equipment is a tried-and-true solution that has helped many firms thrive in the cutthroat food processing industry.

Applications of a Corn Flakes Extrusion Cooking Line

1. Traditional Breakfast Cereals

- The most obvious application is mass-producing classic corn flakes for retail. Manufacturers can create plain, sugar-coated, honey-coated, or vitamin-fortified flakes. Lines can be scaled from medium to large capacity to meet supermarket demand.

2. Private Label Manufacturing

- Retailers and co-packers use extrusion lines to produce private-label corn flakes. The consistent quality and flexible recipes help brands keep costs low while maintaining attractive margins.

3. Snack & Ingredient Production

- Thin flakes can be crushed and used as ingredients in snack bars, coatings, or as a crispy component in ready-to-eat meals. Manufacturers can produce flavored flakes (spicy, cheesy, chocolate-coated) for snack categories.

4. Instant Breakfast Mixes

- Corn flakes can be processed into smaller granules or puffed particles that blend into instant cereal mixes. These are ideal for on-the-go consumers and single-serve sachets.

5. Animal Feed & Pet Food Applications

- Lower-grade flakes or by-products from the flaking process can be repurposed in pet food or animal feed formulations, improving resource efficiency and reducing waste.

6. Specialty and Health-focused Products

- With growing health trends, extrusion lines can produce low-sugar, high-fiber, gluten-free, or organic corn flakes. Fortification with vitamins and minerals is straightforward during the seasoning or enrobing stage.

7. Export-focused Production

- Because the extrusion process can be standardized, factories can produce uniform product lots ideal for export markets. Packaging lines can be adjusted for different languages and regulatory labels.

8. R&D and New Product Development

- Food companies use flexible extrusion lines for pilot testing new recipes — from novel grain blends to functional foods. Fast batch-turnaround helps speed innovation.

Table of Specifications Corn Flakes Cereal Extrusion Cooking Line

| Item | Typical Specification (Example) |

|---|---|

| Product | Corn Flakes Cereal Extrusion Cooking Line |

| Capacity | 300–1000 kg/hr (scalable models available) |

| Main Extruder | Twin-screw co-rotating extruder |

| Screw Diameter | 75–150 mm (model dependent) |

| Motor Power (Extruder) | 55–200 kW |

| Feed System | Volumetric / gravimetric feeders with recipe control |

| Temperature Range (Barrel) | Ambient to 200°C (staged heating zones) |

| Flaking Rollers | Stainless steel heavy-duty, adjustable gap |

| Toaster / Oven | Multi-zone continuous conveyor oven; up to 300°C max |

| Drying System | Hot air dryers with humidity control |

| Flavoring System | Rotary drum or spray applicator |

| Packaging Speed | Up to 40–60 packs/min (depending on pack size) |

| Electric Supply | 380–415 V, 50 Hz (customizable) |

| Footprint | 15–40 m (line length) × 3–6 m width (varies by capacity) |

| Control | PLC with HMI, recipe storage, remote diagnostics |

| Material Contact | SS304 / SS316 (food grade) |

| Cleaning | Semi-CIP / Easy disassembly for full CIP |

| Utilities | Steam, compressed air, chilled water (as needed) |

| Warranty & Support | 12 months standard warranty; lifetime service support available |

Benefits of Corn Flakes Extrusion Cooking Line

- Unmatched Efficiency and Automation: The fully automated extrusion cooking lines from Kriimpas India reduce the need for manual labor and human mistake. Increased manufacturing capacity, reliable product quality, and a notable drop in operating expenses are all results of this automation. You may easily meet market demand and provide impressive results with a single, efficient method.

- Excellent Product Quality: Kriimpas’s extrusion lines precisely regulate temperature, pressure, and moisture to guarantee that every flake is cooked to perfection. Customers will like the product’s consistent texture, exceptional crispiness, and delicious flavor as a result. You can create a consistently high-quality product that fosters brand loyalty if you have complete control over the process.

- Flexibility and Versatility: An extrusion cooking line from Kriimpas India is incredibly versatile. The same line is excellent at making traditional corn flakes, but it may also be used to make a number of other breakfast cereals and snacks, including fortified rice, rings, and stars. Because of this flexibility, companies can expand into new market niches and diversify their product lines without having to make substantial additional investments.

- Complete Assistance and Knowledge: Kriimpas India Pvt. Ltd. is a partner in your success, not merely a supplier of machinery. From plant design and installation to operator training and after-sales servicing, their team of professionals offers complete support. They can assist you in optimizing your production line for optimal profitability because they are knowledgeable about the complexities of the food processing sector.

- Enhanced Profitability: You may cut waste, labor expenses, and create more units per hour by automating the production process and guaranteeing constant quality. This results in a faster return on investment and a healthier bottom line.

- Improved Food Safety: The extruder’s high temperature and high pressure environment efficiently sterilizes the ingredients, lowering the possibility of microbial contamination and guaranteeing a clean and safe end product.

- Innovation and Market Leadership: You may remain ahead of market trends and keep a competitive edge by developing new goods and flavors using your expertise to manufacture a range of forms and textures. Your product’s steady quality will help you establish a solid reputation and become a market leader in morning cereals.

- Sustainable and Effective Operation: The energy-efficient design of contemporary extrusion lines reduces their negative effects on the environment. You may create a more sustainable business model by cutting waste and making the most use of your resources.

Types of Corn Flakes Cereal Extrusion Cooking Lines

Single-Screw Extrusion Lines

- Simple design, lower cost.

- Best for straightforward recipes and medium-low production.

- Easier maintenance but less flexible for complex recipes.

Twin-Screw Extrusion Lines

- More control over cooking, better mixing, higher throughput.

- Ideal for complex formulations (vitamins, proteins, coatings).

- Preferred for large-scale, consistent production.

High-Shear Extrusion Lines

- Provide intense cooking and expansion.

- Used when a lighter, highly-expanded flake is desired.

- Good for special textures.

Puffing and Flaking Combined Lines

- Integrate puffing (for very light products) and subsequent flaking and toasting.

- Useful when producing both puffs and flakes from the same line.

Continuous-toasted Flake Lines

- Designed for continuous toasting with in-line control of color and crunch.

- Saves energy and floor space compared to batch toasters.

Compact Small-Scale Lines

- For pilots, startups and small brands.

- Lower output but lower investment; often modular to allow future scaling.

Conclusion

Think about the amazing journey the little golden flake has taken the next time you pour a bowl of corn flakes. It demonstrates the strength of contemporary engineering and the ingenious science of food processing. More than just a piece of machinery, the Corn Flakes Cereal Extrusion Cooking line is an invention that has made a popular breakfast tasty, reliable, and accessible for millions of people worldwide.

Aspiring food producers have a huge potential to enter this industry. You may transform a basic idea into a lucrative business endeavor with the correct technology and a reliable partner like Kriimpas India Pvt. Ltd. With the correct equipment, every step of the difficult trip from grain to brilliance is an exact and refined art.