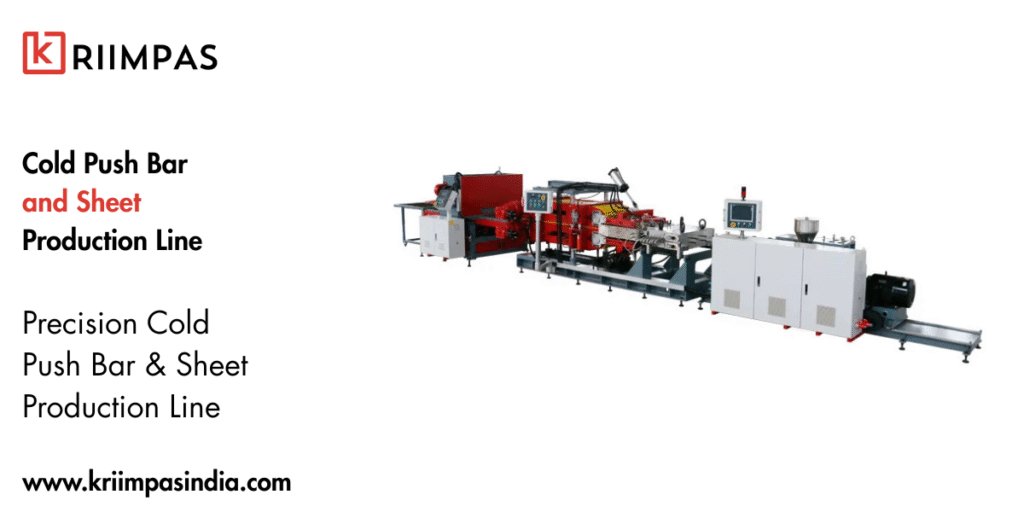

Cold Push Bar and Sheet Production Line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Product quality and manufacturing efficiency are critical for competitive advantage in today’s quickly changing industrial landscape. Kriimpas India Private Limited, a trailblazing manufacturer with a focus on cutting-edge processing machinery solutions, is in the vanguard of this industrial transformation. Kriimpas India is revolutionising the way industries approach the production of plastic and metal sheets with their state-of-the-art Cold Push Bar and Sheet Production Line technologies. This cutting-edge manufacturing technique gives producers in a variety of industries the means to increase productivity while upholding high standards of quality by fusing precision engineering with operational effectiveness. We are the best Cold Push Bar and Sheet Production Line Manufacturer.

What is a Cold Push Bar and Sheet

A Cold Push Bar and Sheet Production Line is an all-inclusive mechanical system that uses cold forming processes to convert raw metal bars and sheets into precisely formed components. Cold push forming, in contrast to conventional hot forging, takes place at or close to room temperature, allowing for better material qualities, tighter tolerances, and superior surface polish. Raw bars and sheets are fed into automated equipment in a production line arrangement to carry out controlled pushing, shaping, cutting, and finishing tasks. The finished goods are prepared for usage in a variety of industries, including heavy machinery, construction, automotive, and aerospace. We are the best Cold Push Bar and Sheet Production Line Supplier.

Why Choose Kriimpas India Pvt. Ltd

1. High Dimensional Accuracy

- Cold push technology ensures tight tolerances and uniform dimensions for both bars and sheets. Unlike hot processes, cold production minimises deformation, resulting in perfectly shaped products that meet strict industry standards without the need for extensive post-processing.

2. Superior Surface Finish

- One of the biggest advantages of a cold push line is the smooth, clean, and defect-free surface finish. This enhances the visual appeal of bars and sheets and reduces additional machining or polishing costs, saving both time and operational expenses.

3. Enhanced Material Strength

- Cold working improves the mechanical properties of the material. The process increases tensile strength, hardness, and durability, making the final products ideal for applications requiring high load-bearing capacity and long service life.

4. Energy-Efficient Operation

- Compared to hot processing methods, cold push production consumes significantly less energy. This leads to lower operational costs, reduced carbon footprint, and an environmentally friendly manufacturing process—an important factor for modern industries.

5. Consistent and High-Speed Output

- The automated nature of the cold push bar and sheet production line ensures continuous, stable, and high-speed production. This consistency helps manufacturers meet bulk demands while maintaining uniform quality across every batch.

6. Versatile Production Capability

- This production line supports a wide range of materials, thicknesses, widths, and bar profiles, making it suitable for diverse industrial applications. Its flexibility allows manufacturers to adapt quickly to changing market requirements.

7. Material & Cost Savings

- With minimal scrap generation and optimised material utilisation, manufacturers can achieve lower raw material wastage and reduced overall production costs. Energy consumption is also lower compared to hot processing methods.

8. Eco-Friendly Manufacturing

- Operating without high-temperature heating makes the process energy-efficient and environmentally friendly, helping manufacturers meet sustainability goals and reduce their carbon footprint.

Applications of Cold Push Bar and Sheet

1. Automotive Industry

- The production line is extensively used in the automotive sector to manufacture components such as body panels, structural reinforcements, and chassis parts. Its precise cold forming process ensures superior dimensional accuracy and consistent mechanical properties, which are critical for vehicle safety and performance.

2. Construction and Infrastructure

- Cold-formed sheets and bars produced by this line are widely applied in construction projects, including roofing, cladding, structural beams, and frameworks. Its ability to produce durable and corrosion-resistant materials ensures long-lasting construction quality.

3. Electrical and Electronics Manufacturing

- High-quality cold-rolled sheets and bars are essential in electrical appliances, transformers, and electronic housings. The smooth surface finish and uniform thickness delivered by this production line enhance conductivity, insulation, and assembly efficiency.

4. Aerospace and Defence

- The aerospace sector requires materials with precise tolerances and excellent strength-to-weight ratios. This production line caters to these needs by producing lightweight, high-strength bars and sheets suitable for aircraft components, military equipment, and defence structures.

5. Packaging Industry

- Aluminium and steel sheets produced through cold pushing and rolling processes are widely used in the packaging industry for making cans, foils, and containers. The line ensures consistent thickness, smooth finish, and superior material integrity, which are crucial for food and pharmaceutical packaging.

6. Machinery and Equipment Manufacturing

- Industrial machinery, agricultural equipment, and heavy-duty mechanical components rely on cold-formed bars and sheets for structural and functional parts. The production line provides high precision, uniform mechanical properties, and excellent surface quality that enhance machine performance and lifespan.

7. Consumer Goods and Household Appliances

- Cold-rolled sheets are frequently used in producing kitchen appliances, furniture, and household products where durability, aesthetic finish, and precision are important. The line enables mass production without compromising quality.

8. Renewable Energy Sector

- Components for solar panels, wind turbines, and other renewable energy systems often require strong, lightweight, and corrosion-resistant metal sheets. The cold push bar and sheet production line efficiently produces these materials to exact specifications, supporting sustainable energy initiatives.

9. General Metal Fabrication

- Beyond specialised industries, this production line is a key asset in general metal fabrication shops for producing raw material that can be further processed through cutting, bending, stamping, or machining into a wide variety of end products.

Specification Table of Cold Push Bar and Sheet

| Parameter | Specification |

|---|---|

| Material | Steel, Stainless Steel, Aluminium, Copper alloys |

| Product Type | Bars & Sheets |

| Output Diameter Range | 6 mm – 60 mm |

| Output Sheet Width | Up to 1000 mm |

| Maximum Output Length | Custom‑configurable |

| Material Compatibility | Steel, Stainless Steel, Aluminum, Copper alloys |

| Production Speed | Up to 60 m/min |

| Forming Method | Cold Push / Cold Heading |

| Power Requirement | 380 V / 50 Hz / 3‑Phase |

| Control System | PLC + HMI |

| Automation Level | Semi‑automatic / Fully automatic options |

| Cooling System | Integrated Liquid Cooling |

| Safety Features | Emergency Stops, Safety Enclosures, Sensors |

| Approx. Machine Footprint (L×W×H) | 20 × 4 × 3 m |

| Installation & Commissioning | Included |

| Warranty | 12 months |

Benefits of Cold Push Bar and Sheet

1. High Precision and Uniformity

- Cold push bar and sheet production lines allow for the production of metal sheets and bars with highly accurate dimensions and tight tolerances. This precision ensures uniform thickness, length, and surface quality across all products, reducing the need for additional processing or finishing.

2. Superior Surface Quality

- Cold-formed products produced using these lines have smooth and clean surfaces without oxidation or scaling, which are common in hot-rolled products. This high-quality surface is ideal for applications where aesthetics and surface finish are critical, such as in automotive, construction, and electronics industries.

3. Improved Mechanical Properties

- The cold forming process strengthens the material through work hardening, enhancing its yield strength, hardness, and wear resistance. This makes the final product more durable and suitable for demanding applications where strength and reliability are essential.

4. Material Efficiency

- Cold push production lines are designed to minimise material waste. Since the process does not involve high temperatures, there is little to no material loss due to oxidation or scaling. This ensures higher yield and cost savings in the long term.

5. Energy Efficiency

- Cold forming consumes less energy compared to hot rolling because there is no need to heat the metal to high temperatures. This results in lower operational costs, reduced carbon footprint, and a more environmentally friendly production process.

6. Versatility in Production

- These production lines can handle a wide range of metals, including steel, aluminium, copper, and alloys. They are capable of producing bars and sheets in various shapes, sizes, and thicknesses, meeting the diverse requirements of different industries.

7. Consistent Production Speed

- Cold push bar and sheet lines are highly automated and can maintain continuous production with minimal downtime. This ensures consistent output and reliable delivery schedules, which are critical for industries relying on just-in-time manufacturing.

8. Reduced Post-Processing

- Due to their precision and smooth surface finish, cold-formed sheets and bars often require minimal post-processing, such as grinding, polishing, or straightening. This not only saves time and labour but also reduces overall production costs.

9. Enhanced Product Strength-to-Weight Ratio

- Cold-formed products typically exhibit higher strength-to-weight ratios compared to hot-rolled equivalents. This is particularly beneficial in automotive, aerospace, and construction applications, where lightweight yet strong materials are in demand.

Types of Cold Push Bar and Sheet

1. Cold Rolling Production Line

- Cold rolling is a highly efficient method used to reduce the thickness of metal sheets and bars at room temperature. This process enhances the mechanical strength, surface quality, and dimensional accuracy of the final product.

2. Cold Drawing Production Line

- Cold drawing is a process where metal bars or wires are pulled through a die to reduce their cross-sectional area and improve surface quality. This method is particularly suited for producing precise bar shapes with excellent dimensional consistency.

3. Cold Extrusion Production Line

- Cold extrusion involves pushing metal through a die to form bars or sheets without heating. This method allows high-speed production with minimal material loss and excellent structural integrity.

4. Cold Laminating and Sheet Forming Line

- Cold laminating lines are used to produce sheets with precise thickness and superior surface quality. This process involves rolling or pressing metal sheets at room temperature, often combined with surface treatments to improve corrosion resistance.

5. Cold Pressing and Bar Forming Line

- Cold pressing lines focus on shaping metal bars through mechanical pressing at ambient temperatures. This method ensures high strength and uniformity without affecting the material’s internal structure.

Conclusion

The Cold Push Bar and Sheet Production Line stands out as a technology that provides accuracy, performance, and financial value in a time when manufacturing excellence is a competitive differentiator. Cold push systems are an attractive option if you want to improve material characteristics, increase throughput, or future-proof your production capabilities. We are the best Cold Push Bar and Sheet Production Line in Gujarat.

At Kriimpas India Pvt. Ltd, we combine industry expertise, engineering innovation, and customer‑centric service to deliver production lines that help your business grow. From design to deployment and ongoing support, we are your trusted partner in metal forming excellence.