Biscuit Extrusion Cooking line Provider

Table of Contents

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Have you ever wondered how those deliciously textured and precisely shaped biscuits are made? The biscuit extrusion cooking line is an intriguing piece of equipment that is frequently used in modern biscuit manufacture, despite the allure of traditional baking techniques. With amazing efficiency and uniformity, this advanced technique turns raw components into biscuit dough that is ready to bake or even eat. We will delve deeply into the realm of biscuit extrusion cooking lines in this post. We are the best Biscuit Extrusion Cooking line Manufacturer.

We’ll go over what they are, how they operate, the advantages they provide, and factors to take into account while selecting one. This guide will provide you a clear and thorough understanding, regardless of whether you’re an experienced biscuit manufacturer trying to improve your operations or someone who wants to know the secret behind your favorite treats.

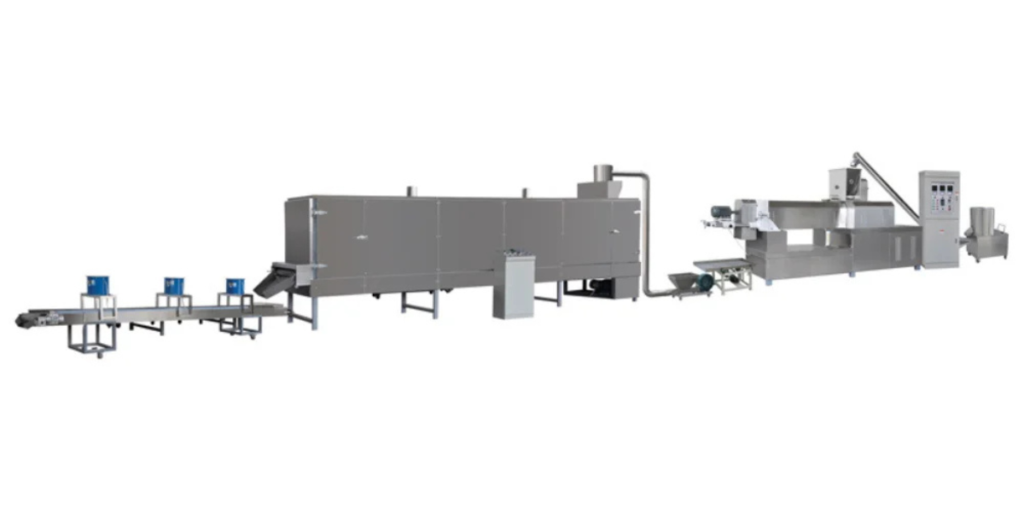

What Exactly is a Biscuit Extrusion Cooking Line

Fundamentally, a biscuit extrusion cooking line is a comprehensive set of equipment intended to combine mixing, partially cooking, and shaping utilizing extrusion technology to transform raw ingredients into biscuit dough. Imagine it as an automated, continuous kitchen designed just for making biscuits. We are the best Biscuit Extrusion Cooking line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Unwavering Durability and Quality: Quality is the top priority at Kriimpas India. The best materials and strict quality control guidelines are used in the engineering and manufacturing of their biscuit extrusion cooking lines. This minimizes downtime and increases your return on investment by guaranteeing sturdy, dependable, and long-lasting equipment that can handle the demands of continuous production.

- Customized Solutions to Meet Your Specific Needs: Kriimpas India is aware that each biscuit company has different needs. They don’t provide a universally applicable solution. Rather, their staff of skilled engineers collaborates directly with you to comprehend your unique product line, production capacity objectives, and facility limitations. After that, they create and modify a biscuit extrusion cooking line to precisely suit your requirements, guaranteeing peak performance and efficiency.

- Innovation & Cutting-Edge Technology: Kriimpas India is dedicated to maintaining its position as a leader in food processing technology. They use the most recent developments in automation, control systems, and processing methods in their extrusion cooking lines. This results in increased productivity, better-quality products, and the capacity to create creative biscuits that satisfy changing consumer needs.

- Complete Support from Inception to Finish: Kriimpas India is dedicated to more than simply supplying the equipment. They provide all-encompassing assistance for the duration of the project. This comprises:

- Dependable After-Sales Support & Service: Kriimpas India recognizes the value of reducing downtime. Their committed after-sales service staff is on hand to offer timely and effective support, including maintenance help, troubleshooting, and easily accessible spare parts. This guarantees your biscuit extrusion frying line will run continuously and effectively.

- A Customer-Centric Approach: Establishing enduring relationships with their clientele is a top priority for Kriimpas India. They are dedicated to comprehending your problems and offering solutions that support you in reaching your corporate goals. You will always receive individualized attention and support because to their customer-centric approach.

- Proven Track Record and Industry Expertise: Kriimpas India has years of experience in the food processing machinery sector and a track record of completing projects successfully and satisfying clients. They have established a solid reputation as a dependable and trustworthy partner because to their in-depth knowledge of biscuit manufacturing procedures and dedication to quality.

- Cost-Effective Solutions: Kriimpas India prioritizes performance and quality while also providing cost-effective solutions that deliver great return on investment. Over time, their dependable machinery and effective designs help to reduce operating expenses.

Applications of Biscuit Extrusion Cooking Lines

- High-Volume Production of Staple Biscuits: Kriimpas India Pvt. Ltd.’s lines provide the ideal answer for producers wishing to efficiently and reliably make huge numbers of common biscuits, such as tea biscuits, crackers, and cookies. High output and uninterrupted operation are guaranteed by their sturdy design.

- Making a Variety of Biscuit Sizes and Shapes: Because of the accuracy and adaptability of their extruders, a vast variety of biscuit shapes and sizes may be produced, allowing producers to satisfy a range of consumer tastes and market niches. The options are endless, ranging from basic geometric forms to more complex creations.

- Easy Production of Filled Biscuits: Kriimpas India Pvt. Ltd. provides co-extrusion technology, which makes it possible to produce filled biscuits with ease. This gives you the chance to make delectable goods with cream, jam, or chocolate centers, enhancing the value and attractiveness of your biscuit line.

- Making Seasoned Biscuits and Savory Crackers: Their product lines can be modified to create delicious crackers and biscuits with different textures and flavorings. This enables producers to take advantage of the expanding market for savory snacks.

- Creating Innovative Biscuit goods: Manufacturers can experiment with novel ingredients, textures, and shapes to create distinctive and inventive biscuit goods that stand out in the market thanks to Kriimpas India Pvt. Ltd.’s sophisticated extrusion cooking lines.

- Ensuring Consistent Quality for Premium Products: Kriimpas India Pvt. Ltd.’s lines are precisely controlled and consistently perform well, ensuring that every biscuit meets the highest standards of quality and consistency for manufacturers who are committed to creating premium, high-quality biscuits.

- Scaling Up Production for Expanding Businesses: As biscuit companies expand, more production capacity is required. Kriimpas India Pvt. Ltd. helps companies increase their market share and reach by providing scalable solutions that can handle rising production demands.

- Optimizing Production Efficiency and Cutting Costs: Their automated extrusion cooking lines help businesses save a lot of money by streamlining the production process, cutting labor expenses, minimizing waste, and increasing overall efficiency.

Specification Table of Biscuit Extrusion Cooking line

| Feature | Specification |

|---|---|

| product | Biscuit Extrusion Cooking line |

| Power Supply | 380V / 50Hz / 3 Phase |

| Material | Food-grade Stainless Steel |

| Extrusion Type | Single/Double Screw Extruder |

| Temperature Control | Digital PID Control |

| Control Panel | PLC with Touch Screen |

| Baking Method | Electric/Gas/Hybrid |

| Cooling Conveyor Length | Customizable |

| Biscuit Shapes Supported | Round, Square, Sticks, Custom Shapes |

| Automation Level | Fully Automatic |

| Safety Features | Emergency Stop, Overload Protection |

| Maintenance Support | On-site and Remote Assistance |

Advantages of Biscuit Extrusion Cooking line

- Versatility: By swapping out the die and modifying the processing parameters, extrusion lines can handle a broad range of raw ingredients and create a variety of biscuit forms, sizes, and textures. This adaptability enables producers to meet various consumer needs and develop cutting-edge goods.

- Efficiency: Compared to conventional batch processing techniques, extrusion cooking produces greater output rates and lower labor costs because it is an automated, continuous operation. Profitability and efficiency are raised as a result.

- Consistency: The product’s shape, size, texture, and moisture content are all consistently guaranteed by the exact control over processing parameters. Sustaining client satisfaction and brand reputation depends on this.

- Better Product Quality: Better product digestibility and nutritional value may result from the extruder’s vigorous mixing and cooking activity. In addition to improving food safety, the high temperatures can aid in the inactivation of dangerous germs.

- Cost-Effectiveness: Although an extrusion line may require a large initial investment, it is a cost-effective option over the long run because of the labor, energy, and waste reductions it provides.

- Area Optimization: Compared to conventional biscuit manufacturing setups, extrusion lines are typically smaller, which maximizes industrial floor area.

- Energy Efficiency: In order to reduce energy consumption, modern extrusion lines are built with energy efficiency in mind. Features like insulated barrels and effective motor drives are included.

- Formulation Flexibility: A greater variety of components, including those with different functions and particle sizes, can be incorporated thanks to extrusion cooking.

Types of Biscuit Extrusion Cooking Lines

- The most popular kind of extruders use a single rotating screw inside a barrel to move, combine, and form the dough. They work well with a variety of biscuit varieties and are adaptable.

- Twin-Screw Extruders: These extruders provide more intensive mixing, conveying, and cooking capabilities by using two intermeshing screws. When more intricate dough formulations or higher levels of pre-gelatinization are needed, they are frequently chosen.

- Steam-Based Systems: These lines heat and pre-cook the dough by injecting steam either inside the extruder barrel or in a separate conditioning chamber. This works very well for enhancing dough machinability and gelatinizing starches.

- Systems for Infrared (IR) Heating: These lines use infrared emitters to quickly heat the extruded dough’s surface, forming a skin layer and lowering moisture content.

- Microwave Heating Systems: The volumetric heating that microwave radiation produces can be useful for obtaining consistent pre-cooking throughout the biscuit’s structure.

- Drop cookies and other biscuits with irregular shapes are made with wire-cut extruders. A wire splits the dough into separate pieces after it has been extruded as a continuous sheet or strands.

- Rotary Moulders: These mold soft doughs using a revolving drum with etched cavities. The formed pieces are then released onto a conveyor once the dough has been squeezed into the cavities.

- Lines for sheeting and cutting: Some lines, though not precisely “extrusion cooking” in the same sense, include sheeting the dough and then cutting it into different shapes with rotary cutters before partially heating it. These frequently fall under the more general heading of automated pre-treatment and biscuit formation.

Conclusion

A key component of contemporary biscuit production, the biscuit extrusion cooking line provides a potent blend of effectiveness, adaptability, and quality control. Manufacturers of biscuits can greatly improve their production capacities and satisfy changing consumer needs by being aware of the various line types available and selecting the best supplier. We are the best Biscuit Extrusion Cooking line Manufacturer in Gujarat.

Our goal at Kriimpas India Pvt. Ltd. is to give our clients the best biscuit extrusion cooking solutions available. We are the perfect partner in attaining biscuit manufacturing excellence because of our wide variety of single-screw, wire-cut, rotary molder, and combined lines, as well as our experience and dedication to client pleasure.