Baby Foods Extrusion Cooking line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

The most crucial components of infant meals are not only fruits and vegetables but also safety, nourishment, and trust. Nowadays, parents are more knowledgeable and discriminating than ever before, looking for items that are not only practical but also healthy, easily absorbed, and devoid of dangerous ingredients. Advanced production technology can help with this, and the baby food extrusion cooking line is at the center of this revolution. We are the best Baby Foods Extrusion Cooking line Manufacturer.

The term “extrusion” may seem complicated or unduly technical to many people. To put it simply, it is a revolutionary method that has changed the way we produce safe, wholesome, and high-quality Foods for babies and toddlers. This post will go into great detail on baby food extrusion cooking, including the technology, its many advantages, and why choose the proper production line partner is the most important choice you can make. Additionally, we will highlight a business that is spearheading this movement in India and elsewhere: India’s Kriimpas Pvt. Ltd.

What is Baby Food Extrusion Line

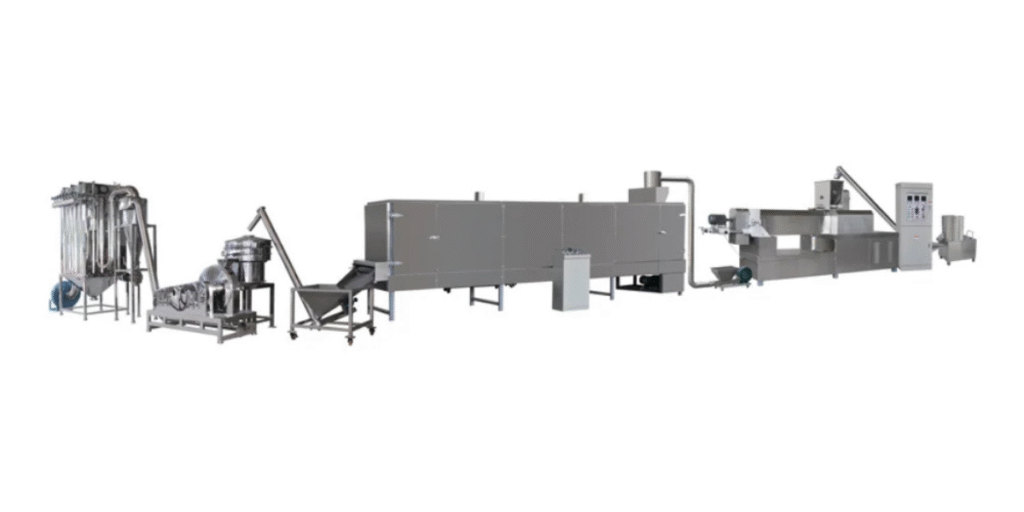

Consider a system that continuously and incredibly efficiently takes raw materials, mixes them, cooks them, and forms them. In essence, an extrusion cooking line accomplishes that. A machine known as an extruder is fed a mixture of substances, such as grains, powders, and liquids, to carry out the operation.

The ingredients are moved forward inside the extruder by a big, revolving screw.High pressure and heat are applied to the substances as they move. The “cooking” portion of the procedure is this. The food is cooked quickly often in a matter of seconds by the extreme heat and pressure. The “High-Temperature Short-Time method is what makes extrusion so successful for infant food, thus this is an important aspect. We are the best Baby Foods Extrusion Cooking line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Knowledge and Experience: Having been in business since we possess a thorough awareness of the complexities involved in food preparation. We apply the same level of accuracy and commitment to our infant food lines that our team of professionals has brought to the design and delivery of sturdy, effective, and dependable machinery for a variety of food products.

- Complete Solutions: For all of your needs related to the manufacture of baby food, we provide a comprehensive, end-to-end solution. Our lines can be tailored to your unique capacity needs and are completely automated. Our machines are designed for maximum performance and hygiene, from extruders that gently cook and shape the product to blenders that guarantee a consistent texture. Additionally, we offer cutting-edge packaging and milling equipment to guarantee the best quality and longest shelf life for your finished product.

- Unwavering Dedication to Quality: We use premium, food-grade raw materials in the precise engineering of our machinery. We make sure that every machine we manufacture is dependable, long-lasting, and simple to maintain by adhering to strict industry standards. Our equipment reflects our understanding that safety and quality cannot be compromised when it comes to infant food.

- Committed Support and Service: Kriimpas values enduring connections with its customers. They offer a wide range of assistance, such as continuing technical support and maintenance, thorough training for your employees, and the installation and commissioning of the machines. This guarantees optimal uptime and seamless operations for your company.

- Dedication to Safety and Quality: All Kriimpas equipment is constructed from premium stainless steel, guaranteeing longevity and hygienic conditions. They are aware that safety cannot be compromised when it comes to infant food. The most exacting industrial requirements are met in the construction of their machines.

- Personalization for Your Requirements: Every company is different. Whether you are starting small or expanding to satisfy a significant market demand, Kriimpas will help you understand your unique needs and can design a baby food extrusion line to fulfill your production goals.

- Modern Technology: To guarantee optimal efficiency and exceptional product quality, our extrusion cooking lines are constructed with the newest technology. We utilize premium, food-grade stainless steel ingredients and provide accurate temperature and pressure controls so you may make a variety of safe and wholesome baby food products.

Applications of Baby Foods Extrusion Line

Instant Baby Cereal Powder

- Made from rice, wheat, corn, or oats, our extrusion lines can produce fine powders that dissolve easily in milk or water.

Fruit & Vegetable Blends

- By integrating fruit or vegetable pulp into the extrusion process, manufacturers can create nutrient-rich baby meals.

Dairy-Based Baby Foods

- Using milk powder or whey protein as a base, you can produce calcium-rich formulas for growing infants.

Gluten-Free Baby Food

- With growing awareness of gluten intolerance, our equipment allows production of gluten-free alternatives using rice or maize.

Allergen-Free Baby Meals

- Our machinery is designed to handle specialized formulas that exclude common allergens like soy, dairy, or nuts.

Snacks for Toddlers

- Healthy, puffed snacks in star or ring shapes that melt easily in the mouth.

Fortified Powder Mixes

- Iron, calcium, and vitamin-enriched powders for improving immunity and growth.

Infant Cereals

- Wheat, rice, ragi, and multigrain-based cereals with milk powder and nutrients.

Instant Porridges

- Just add water convenient and nutritious for mothers on the go.

Table of Specifications Baby Foods Extrusion Line

| Feature | Specification |

|---|---|

| Product | Baby Food Extrusion Line |

| Production Capacity | 100 – 500 kg/h |

| Raw Material | Rice, corn, wheat, oats, pulses |

| Power Requirement | 75 kW (average) |

| Extruder Type | Twin-screw extruder |

| Heating System | Electric heaters with PID control |

| Control Panel | PLC-based with touchscreen |

| Dryer Type | Multi-layer hot air dryer |

| Final Product Form | Powder, flakes, granules |

| Material | SS304 contact parts |

| Automation Level | Fully Automatic |

| Installation & Training | Included |

| Warranty | 1 Year |

Advantage of Baby Foods Extrusion Line

- Improved Absorption of Nutrients and Digestibility Starch gelatinization is the result of extrusion cooking’s high temperature and pressure. As a result, complicated starches are broken down into easier-to-digest molecules. This is revolutionary for a baby’s developing digestive system. It lowers the possibility of digestive discomfort by facilitating their bodies’ easier absorption of the nutrients and energy from the food.

- Elimination of Pathogens and Anti-Nutritional Factors Phytates and tannins are examples of “anti-nutritional factors” (ANFs) found in a variety of uncooked grains and legumes. These substances may hinder the body’s absorption of vital minerals such as calcium, zinc, and iron. These ANFs are successfully neutralized by the extrusion process, increasing the minerals’ absorption capacity. To ensure a safe and hygienic product, the HTST process also lowers microbial contamination and gets rid of dangerous bacteria.

- Strengthening for Maximum Development Easy fortification of infant food with vital vitamins and minerals is one of the extrusion line’s most potent advantages. Important nutrients such as iron, zinc, and various B vitamins can be added to the raw materials as they are being mixed. In order to treat common micronutrient shortages and promote healthy newborn development, this is an essential first step.

- Increased Shelf Life and Quality Maintenance Extruded items have a longer shelf life because of their low moisture content and quick processing time. Both consumers and manufacturers really benefit from this. Without the need for chemical preservatives, the baby food will remain fresh, safe, and nourishing for an extended amount of time thanks to the airtight packing and hygienic processing.

- Adaptability and Personalization A cooking line that uses extrusion is very adaptable. Manufacturers may create a vast range of infant Foods , from fine powders and porridges to textured snacks for older toddlers, by simply changing the raw materials, the die shape, and the process settings. This makes it possible to be creative and produce goods that meet the changing demands and tastes of newborns as they get older.

- Increased Nutritional Value: Extrusion increases the food’s nutritional value by denaturing proteins and gelatinizing starch, which makes the nutrients easier for infants to absorb and digest. A baby’s body can absorb more of the essential vitamins and minerals it requires for optimal growth when anti-nutritional factors are reduced.

- Enhanced Food Safety: To guarantee that the food is sterile and to eradicate microorganisms, the HTST procedure is a very efficient method. Knowing that the food they are feeding their child is healthy and devoid of dangerous microorganisms provides parents piece of mind.

Types of Baby Foods Extrusion Lines

1. Single-Screw Baby Food Extrusion Line

- Ideal for startups or small-scale producers.

- Low investment cost.

- Suitable for basic cereal-based baby Foods.

- Compact design with easy operation.

2. Twin-Screw Baby Food Extrusion Line

- Suitable for large-scale, high-output production.

- Offers better mixing, shearing, and cooking efficiency.

- Can handle diverse ingredients, including proteins and fiber-rich additives.

- Ensures precise control of texture and taste.

3. High-Capacity Continuous Extrusion Line

- Designed for multinational brands and large industrial units.

- Full automation with recipe memory and PLC control system.

- Can produce over 1000 kg/h.

- Supports integration with packaging systems.

4. Multifunctional Baby Food Extrusion Line

- Can produce baby cereal, rice powder, protein powder, and instant porridge.

- Adjustable to make products with different nutritional levels and textures.

- Customizable die shapes and drying systems.

Conclusion

Extrusion cooking is at the vanguard of a revolution in the baby food industry. It provides a method for creating food that is not only practical but also safer, healthier, and simpler for infants to digest. Food producers can use this technology to provide premium, enriched items that satisfy the needs of contemporary parents and support their kids’ healthy growth.

Take into consideration the tried-and-true method of extrusion cooking if your company wants to enter the future of food production, especially in the infant food industry. We at Kriimpas India Pvt. Ltd. are your go-to partner for dependable, effective, and cutting-edge machinery solutions. Our dedication to quality and client pleasure motivates us to assist you in producing wholesome treats for the coming generation.