Auto Weiging And Packing Units Provider

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

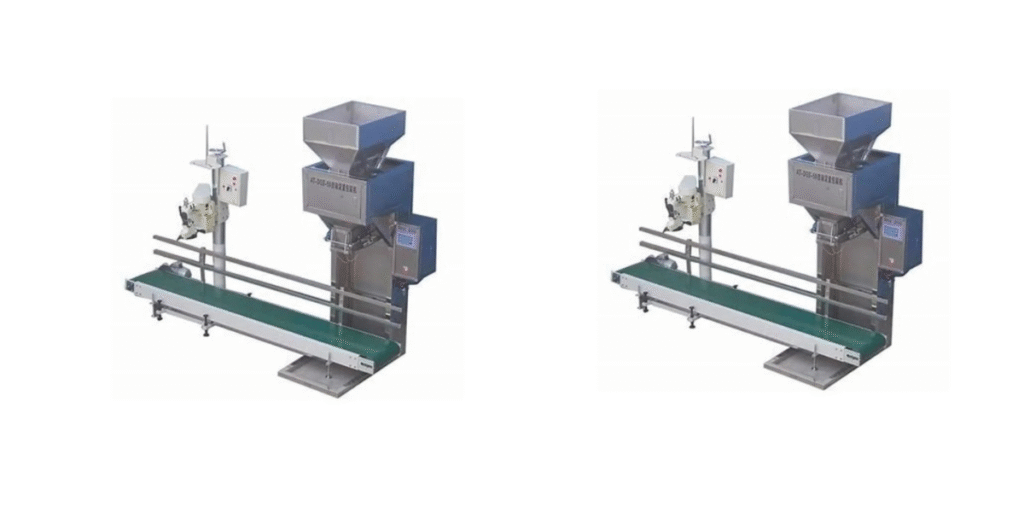

In today’s fast-paced world, where consumers demand consistent quality and businesses strive for peak efficiency, the manufacturing landscape is undergoing a significant transformation. Auto Weighing and Packing Units, which are highly advanced pieces of equipment that automate accurate product measurement and packaging, are at the center of this revolution. These silent workhorses are revolutionizing production lines in a wide range of industries they are more than just machines.I’m sure you’ve heard the chatter if you work in manufacturing. Automation is no longer a luxury it’s a must for staying competitive. Furthermore, the advantages of switching to automatic packing are just too great to be overlooked. We are the best Auto Weiging And Packing Units Manufacturer.

Understanding Auto Weighing and Packing Units

Auto weighing and packing units: what are they? They are essentially integrated systems made to precisely weigh goods and subsequently package them into different bags or containers without requiring continual human supervision. Consider them highly intelligent robots that perform the repetitive, meticulous tasks of packaging and measuring. We are the best Auto Weiging And Packing Units Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Knowledge and Experience: Kriimpas India Pvt. Ltd. has a solid foundation dating back to and a plethora of experience in producing sturdy and dependable industrial machinery. Our team of highly qualified experts has extensive knowledge of the industry and puts forth endless effort to provide solutions that satisfy the highest requirements.

- Dependable Quality: At Kriimpas, quality is a commitment rather than only a promise. Using the newest technology and finest raw materials obtained from reliable suppliers, we painstakingly engineer our products. Our automatic weighing and packing devices are designed to last, be accurate, and operate reliably, reducing downtime and increasing productivity. We know that accuracy is crucial when it comes to packing and weighing, and our machines are built to provide just that.

- Standard and Customized Solutions: We are aware that every company has different needs. Kriimpas India Pvt. Ltd. has the capacity and adaptability to provide a basic auto weighing and packing unit or a specially made solution to match your unique product, space requirements, or production volume. In order to give our clients with machinery that effortlessly fits into their current operations, we work closely with them to understand their demands.

- Extensive Support and Service: After the sale, our partnership with you continues. Kriimpas India Pvt. Ltd. is dedicated to offering top-notch post-purchase assistance, encompassing installation, instruction, and upkeep services. We are committed to establishing enduring relationships so that your machines continue to function effectively and easily for many years to come. Our timeliness and dedication to quality and delivery are frequently emphasized in our customer feedback.

- Technological Development: To remain on the cutting edge of technological developments in the equipment industry, we consistently make investments in research and development. Modern sensors, clever algorithms, and sturdy mechanical designs are all used in our auto weighing and packing systems to guarantee precision, speed, and user-friendliness.

- Dedication to Your Success: Your success is our success at Kriimpas India Pvt. Ltd. In order to help you increase production yields, lower operating costs, and strengthen your competitive edge in the market, we are committed to offering solutions that not only meet but also beyond your expectations. Our goal is to become your reliable partner as you increase your manufacturing capacity.

- Diverse Industry Applications: Although we offer a wide range of products to meet the needs of the plastics processing industry, our primary engineering capabilities include the design and production of dependable machinery for a range of uses. Because of our extensive experience, we are able to provide appropriate auto weighing and packing machines for granules, powders, and other materials while also comprehending the subtleties of various sectors.

Applications of Auto Weighing and Packing Units

- Food & Beverage: These machines provide precise portions and hygienic packing for anything from frozen foods, fruits, and vegetables to snacks, grains, spices, chocolates, and coffee. This prolongs shelf life and preserves product quality.

- Pharmaceuticals: In the pharmaceutical industry, accuracy is essential. To ensure dose precision and adherence to stringent regulatory criteria, auto machines precisely weigh and package tablets, capsules, powders, and other pharmaceutical items.

- Chemicals: These devices manage accurate weighing and safe packaging for powdered detergents, fertilizers, industrial chemicals, and pigments; they frequently handle corrosive or hazardous materials in a safe manner.

- Cosmetics and Personal Care: These automated systems provide precise filling and visually appealing packaging for lotions, creams, powders, and other personal care products.

- Agriculture: Precise weighing and bagging of seeds, animal feed, and fertilizers guarantees reliable product delivery to farmers and customers.

- Hardware and Industrial Goods: It is possible to efficiently weigh and package small parts, such as screws, nuts, and bolts, as well as larger industrial components for distribution.

- Rice, lentils, sugar, coffee beans: and other free-flowing granules can be packed into different bag sizes with efficiency.

- Powdered Products: Accurate filling of flour, milk powder, coffee powder, spices, and other finely ground ingredients; frequently, special feeders are needed to avoid caking.

- Frozen Foods: Preserving product integrity by carefully handling fragile and irregularly shaped frozen foods.

- Dairy Products: Strictly hygienic packaging for cheese cubes, powdered milk, and other dairy products.

Specification Table of Auto Weighing and Packing Units

| Feature | Specification |

|---|---|

| Product | Auto Weighing and Packing Units |

| Weighing Capacity | 5 kg to 50 kg |

| Packing Speed | Up to 8-12 bags/min (based on material) |

| Accuracy | ± 0.2% |

| Weighing Mechanism | Load cell based |

| Control Panel | PLC with HMI Touch Screen |

| Power Requirement | 220V/440V, 3-Phase, 50 Hz |

| Air Requirement | 6 CFM @ 6 bar |

| Bag Type Supported | Woven sack, laminated pouch, PP bags |

| Material Contact Parts | SS304 / SS316 (customized on request) |

| Machine Structure | MS powder-coated / Stainless Steel frame |

| Sealing Options | Stitching / Heat sealing / Gluing (Optional) |

| Output Conveyor | Included |

| Footprint Area | 2.5m x 1.5m x 2.2m |

| Optional Add-ons | Bag holding clamp, Dust collector, Printer |

Benefits of Auto Weighing and Packing Units

- Decreased Product Giveaway: Sophisticated sensors and clever software make sure that every package weighs precisely the right amount. This reduces overfilling waste, which has an immediate effect on your profitability.

- Consistent Quality: All of the packages adhere to the same exacting weight and fill requirements, which guarantees consistency and improves the quality reputation of your company. No more complaints from customers about different product quantities.

- Increased Production Capacity: You can process big quantities of items in a fraction of the time with auto weighing and packing devices because they run at much higher speeds than manual techniques. This implies that you can scale your business effectively and readily satisfy rising market demand.

- Faster Turnaround Times: Shorter packaging times result in faster order fulfillment, which boosts supply chain effectiveness and speeds up product launch.

- Reduced Labor Costs: You can cut labor costs on the packing line by automating repetitive processes. Your staff can now concentrate on more valuable and skilled tasks for your company.

- Reduced Material Waste: By precisely distributing the amount required for each product, these machines are made to maximize the use of packaging materials. This decreases your overall packaging costs and minimizes material waste.

- Decreased Rework and Returns: You can save time and money by reducing product rejection, rework, and customer returns due to increased accuracy and consistency.

- Streamlined Workflow: By incorporating auto weighing and packing equipment into your current production line, bottlenecks are removed and a steady, uninterrupted product flow is guaranteed.

- Real-time Data and Control: A lot of contemporary units have the ability to gather data, which offers important information about production rate, material consumption, and possible downtime. You may further optimize your operations and make well-informed decisions with the help of this data.

- Increased Safety: By automating repetitive and physically taxing operations, you can lower the chance of workplace accidents and make your workplace a safer place for your workers.

Types of Auto Weighing and Packing Units

1. Vertical Form Fill Seal (VFFS) Machines

- These machines are ideal for granular or powdery products like rice, sugar, pulses, and spices. They create packets from roll film, fill them, and seal them vertically.

Features:

- PLC controlled operation

- Customizable pouch size

- High-speed performance

2. Auger Filler Machines

- Best suited for powders such as flour, coffee, milk powder, and chemical powders. The auger system ensures precise and consistent powder dispensing.

Features:

- Dust-free filling

- Easy to clean and maintain

- High-accuracy weight system

3. Multi-Head Weighing Machines

- These are best for fragile or irregular-shaped items like snacks, dry fruits, chips, or candies. They come with multiple weighing heads that ensure accurate combination weights.

Features:

- Fast & flexible

- Suitable for non-uniform products

- Reduced product waste

4. Cup Filler Packing Machines

- These are simple and economical options for free-flowing materials such as rice, pulses, tea, and grains. Pre-set cups are used for measuring product volume.

Features:

- Easy to operate

- Affordable and durable

- Consistent cup filling

5. Bulk Bagging Units

- Used for large-scale industrial materials like fertilizers, cement, or animal feed. These units can fill and seal 10kg to 50kg bags with ease.

Features:

- Heavy-duty construction

- Suitable for industrial plants

- Durable and long service life

Conclusion

Unquestionably, automated production is the way of the future, and auto weighing and packing machines are leading the way in this change. Purchasing machinery is only one aspect of investing in these cutting-edge systems; other benefits include improved quality, lower costs, higher productivity, and a more competitive position in the market. We are the best Best Auto Weiging And Packing Units Provider.

By selecting Kriimpas India Pvt. Ltd. as your provider of auto weighing and packing units, you are choosing a collaboration that combines knowledge, creativity, and steadfast assistance. Allow us to assist you in optimizing your business processes, reaching new heights of productivity, and laying the foundation for a more lucrative and sustainable future. To find out how we can create a solution that precisely meets your needs, get in touch with us right now.