Auger Feeders Provider in Gujarat

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Gujarat is a major force in Indian business because of its booming ports, robust manufacturing sectors, and strong sense of entrepreneurship. The state is a center of production for everything from petrochemicals to textiles, pharmaceuticals to food processing. However, the Auger Feeder is a workhorse that keeps things running smoothly behind the scenes of these enormous businesses. We are the best Auger Feeders Supplier.

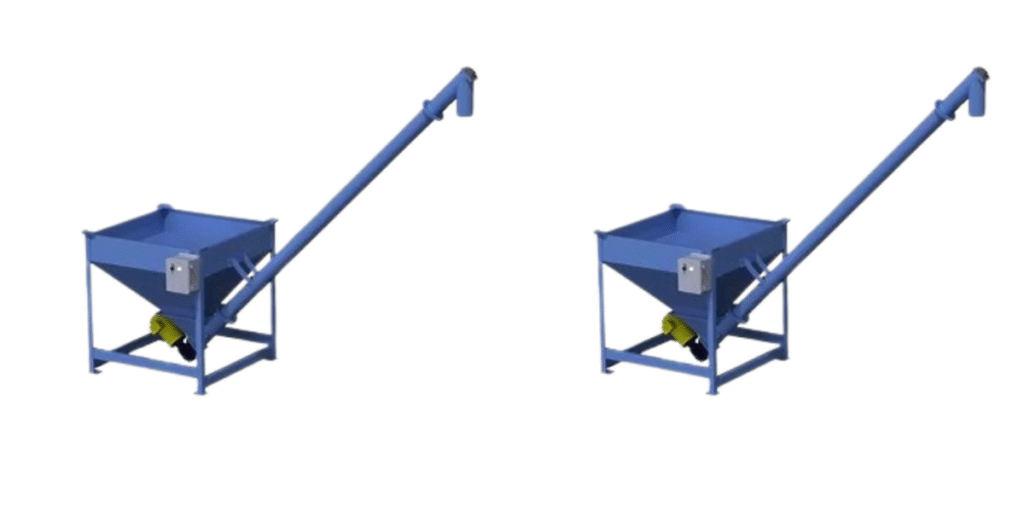

An auger feeder is a straightforward but remarkably efficient device, for those who are unfamiliar with the name. Imagine it as a corkscrew or mechanical screw inside a trough or tube. Moving a wide range of materials from smaller powders and granules to larger pellets and flakes is its responsibility. It is a flexible instrument used in many different sectors since it can move materials vertically, horizontally, or at an angle.

Why Auger Feeders

An auger feeder is a machine that transfers materials from one location to another by means of a revolving screw known as an auger. Cement, plastic granules, grains, powders, and other like materials are frequently handled with it. These feeders are ideal for sectors that demand precise dosing and low waste because of their ability to transport material in a regulated and metered manner. We are the best Auger Feeders Manufacturer.

Why Choose Kriimpas India Pvt. Ltd

While there are many providers of material handling equipment in Gujarat, Kriimpas India Pvt. Ltd. stands out as a leader in innovation and reliability. We are not just a manufacturer; we are a partner dedicated to optimizing your material handling processes.

- Customized Solutions: We are aware that every application and every sector has different needs. There is no one-size-fits-all strategy that we support. In order to develop and construct an auger feeder that is ideal for your process, our team of professionals works closely with you to understand your unique demands, including the kind of material you handle, the required feed rate, and your operational limits.

- Superior Quality and Durability: To guarantee that our auger feeders are constructed to last, we only utilize the best materials and cutting-edge production processes. Our equipment is renowned for its sturdy design and wear-resistant elements, which reduce maintenance expenses and downtime.

- Hygiene and Safety First: We provide auger feeders with food-grade stainless steel and hygienic designs that are simple to clean and maintain for sectors with high hygiene requirements, such as the food and pharmaceutical industries. Your employees will operate in a safe and dust-free environment thanks to our enclosed systems.

- Proven Expertise: Having worked in the industry for many years, we possess a thorough awareness of the subtleties and difficulties involved in material handling. Beyond the auger feeder itself, we provide comprehensive solutions that may be easily integrated with your current manufacturing lines.

- Devoted Customer Service: We are dedicated to establishing enduring bonds with our customers. Our staff is available to help you whenever you need it, from the first consultation through installation, training, and post-purchase support.

- Deep-Rooted Expertise: We have the technological know-how to design and produce auger feeders that satisfy the highest performance and reliability criteria thanks to a team of seasoned engineers and a strong emphasis on research and development. We can provide the ideal solution for your application because we are aware of the distinct flow properties of different materials.

- Sturdy and Dependable Products: We make auger feeders that are meant to last. We guarantee outstanding longevity and low maintenance by using premium-grade materials and cutting-edge production processes. More uptime and a larger return on investment result from this.

- Customization at Its Heart: We think that every company is different. To precisely meet your production needs, we provide a broad range of customization choices, such as various screw sizes, hopper designs, and control systems. We have the know-how to provide a single-screw, twin-screw, or vertical auger feeder, depending on your needs.

- Complete Solutions, Not Just Products: We offer more than just manufacturing services. From initial design and advice to installation and post-purchase assistance, we offer a comprehensive range of solutions. Our staff is committed to making sure your system functions properly, providing support for maintenance and troubleshooting whenever you require it.

- A dedication to customer success: We succeed when you succeed. We take great satisfaction in establishing enduring connections with our customers by giving them the dependable and effective equipment they require to remain competitive. We provide unmatched customer service and are always willing to go above and beyond to make sure you’re satisfied.

Applications of Auger Feeders

1. Food Industry

- Used to feed powders like flour, spices, sugar, and salt into packaging machines or mixers.

- Maintain hygiene standards due to stainless-steel construction.

2. Pharmaceutical Industry

- Ideal for transferring fine powders in capsule filling, tablet making, or mixing.

- Ensures dust-free operation and accuracy in dosages.

3. Chemical Industry

- Used for handling aggressive or hazardous chemicals in powder or granule form.

- Supports safe and efficient material transport in controlled environments.

4. Plastic and Polymer Industry

- Feeders supply granules or pellets into injection molding or extrusion machines.

- Helps maintain consistent flow during production.

5. Agriculture and Animal Feed

- Used to feed grain, powdered feed, or fertilizer into processing or mixing systems.

- Durable for rugged, outdoor use.

6. Construction and Cement

- Convey powdered cement, lime, and other building materials to batching plants.

- Resistant to heavy and abrasive materials.

5. Construction Industry

- Used for feeding cement, sand, fly ash, and other construction materials.

Specification Table of Auger Feeders

| Parameter | Specification |

|---|---|

| Product | Auger Feeders |

| Material of Construction | SS304 / SS316 / MS Powder Coated |

| Feeding Capacity | 10 kg/hr to 1000 kg/hr |

| Screw Diameter | 50 mm to 200 mm |

| Screw Type | Full Pitch / Variable Pitch |

| Drive Type | Geared Motor / VFD Controlled |

| Power Requirement | 0.5 HP to 5 HP |

| Hopper Size | Customizable |

| Discharge Height | Up to 5 meters |

| Control Panel | PLC Based / Manual |

| Surface Finish | Mirror / Matte / Coated |

| Optional Features | Vibratory Hopper, Level Sensor, Wheels |

The Benefits of Auger Feeder

- Perhaps the most significant advantage is accuracy and precision. The precise amount of material is always provided thanks to a top-notch auger feeder. This reduces waste, enhances product quality, and satisfies the exacting standards needed by numerous sectors.

- Enhanced Efficiency: Auger feeders streamline the production process and boost total output by eliminating bottlenecks and manual handling by supplying a constant and regulated flow of material.

- Versatility: A well-designed auger feeder can be modified to process a variety of materials, such as abrasive materials, cohesive materials that have a tendency to clump, and free-flowing powders. Because of its adaptability, it is a great benefit for businesses with a variety of product lines.

- Improved Safety and Lower Labor Costs: Automated feeding systems eliminate the need for manual material handling, which decreases labor costs and reduces the possibility of accidents at work caused by lifting and dumping large sacks.

- Space-Saving form: In many industrial situations where floor space is limited, auger feeders particularly the tubular variety have a compact form that allows for installation in confined spaces.

- Low Maintenance: Because auger feeders have few moving parts, they are typically sturdy and require little maintenance, which lowers operating costs and downtime.

- Sanitary Design: Hygiene is a major concern for sectors such as food and pharmaceuticals. High-quality stainless steel with polished surfaces can be used to make auger feeders, guaranteeing simple cleaning and adherence to stringent sanitary standards.

- Decreased Labor and Cost: Auger feeders reduce the requirement for manual labor, which can be labor-intensive and prone to human mistake, by automating the material transfer process. This lowers operating expenses and the possibility of workplace accidents in addition to increasing efficiency.

- Space-Saving Design: Auger feeders take up little room, particularly the vertical and inclined varieties. They are an excellent option for organizations with limited space since they can be incorporated into current manufacturing lines without consuming valuable floor space.

Types of Auger Feeders

1. Vertical Auger Feeders

- These are ideal for lifting materials to a height in vertical direction. Mostly used in plastic granule loading and food processing units.

Key Features:

- Compact design

- Energy-efficient motor

- Smooth upward flow of materials

2. Horizontal Auger Feeders

- Used when the material needs to be conveyed in a straight horizontal direction. Perfect for small spaces and easy integration with other machines.

Applications:

- Packaging lines

- Powder transfer in pharmaceuticals

- Continuous feeding to mixers

3. Inclined Auger Feeders

- Inclined feeders are designed to lift and feed materials at a certain angle. These are a hybrid between vertical and horizontal feeders.

Best For:

- Feeding into hoppers

- Granule filling in high-speed machines

- Compact plant layouts

4. Twin Screw Auger Feeders

- These feeders have two screws rotating together to handle larger quantities or sticky materials.

Advantages:

- Higher throughput

- Better control of material flow

- Useful in high-capacity applications

5. Volumetric Auger Feeders

- These feeders deliver material based on volume, ensuring consistent flow per cycle. Ideal when weight-based precision is not required.

Uses:

- Spices, flour, cement

- Fertilizer manufacturing

- Detergent powders

Conclusion

Accuracy and efficiency are not just benefits but also essentials in Gujarat’s competitive and dynamic industrial environment. A key element in accomplishing these objectives is the use of auger feeders, which offer the steady and regulated material flow required for superior production. We are the Best Auger Feeders Provider.

Selecting the ideal partner for your Auger Feeder requirements may make all the difference. By fusing years of experience with an unwavering focus on quality, personalization, and customer service, Kriimpas India Pvt. Ltd. has become a leader in this industry. We are committed to assisting your company in realizing its full potential and are more than just a supplier of machinery.