Aluminium Plastic Composite Plate Extrusion Line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Modern materials are displacing older options in today’s fast-paced industrial and construction environment because of their strength, efficiency, and aesthetic appeal. The Aluminium Plastic Composite Plate a material that flawlessly blends functionality, durability, and beauty is one such ground-breaking innovation. Because of their strength, efficiency, and aesthetic appeal, modern materials are replacing older options in today’s fast-paced industrial and construction environment. One such ground-breaking invention is the Aluminium Plastic Composite Plate a material that perfectly combines durability, attractiveness, and practicality. We are the best Aluminium Plastic Composite Plate Extrusion Line Manufacturer.

What is an Aluminium Plastic Composite Plate

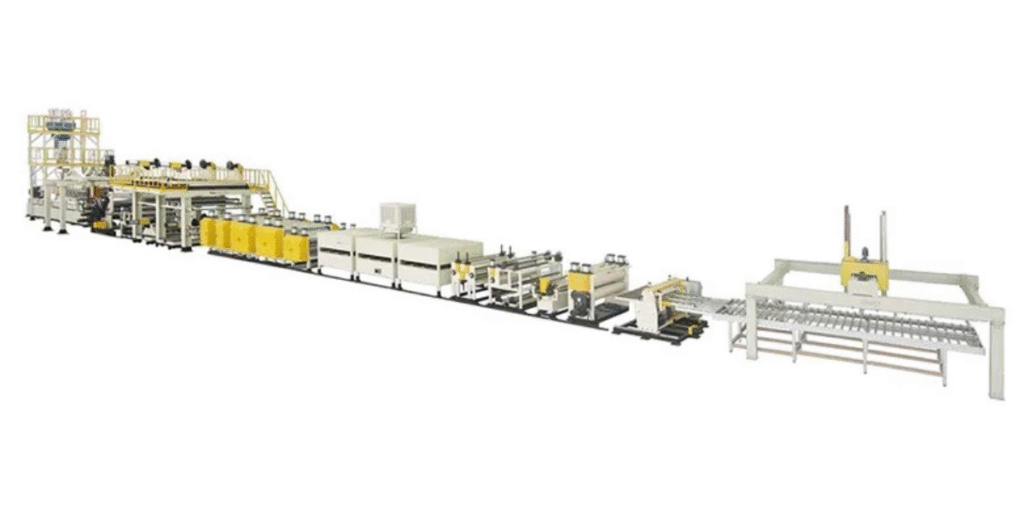

A sandwich panel composed of two thin aluminum sheets bonded to a thermoplastic core—typically polyethene (PE) or fire-retardant material—is called an aluminum plastic composite plate, or ACP sheet. Because these plates are lightweight, strong, and aesthetically pleasing, they are frequently utilized for building facades, signage, interiors, walls, and cladding systems. The equipment used to produce these composite panels consistently and precisely is called the Aluminum Plastic Composite Plate Extrusion Line. We are the best Aluminium Plastic Composite Plate Extrusion Line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Unmatched Production Capacity and Speed: This is the most obvious advantage. A larger line is built for speed and volume. It can process wider aluminium coils and run at higher linear speeds, churning out significantly more square meters of panels per hour. This allows you to meet large orders, reduce delivery times, and scale your business effortlessly.

- Handling Wider Panels with Ease: The market demand for wider sheets is growing, especially in architectural applications where fewer seams mean a cleaner, more aesthetic look. A large extrusion line is specifically designed to produce these wider panels (e.g., 1600mm, 2000mm, or more) without compromising on quality or stability.

- Enhanced Durability and Lower Downtime: Large lines are not just bigger they are engineered with industrial-grade, heavy-duty components. From the decoilers and extruder to the laminating rolls and haul-off units, every part is built to withstand operation. This means less wear and tear, reduced maintenance, and significantly lower machine downtime, which directly translates to higher profitability.

- Future-Proofing Your Investment: Investing in a large line positions your company for future growth. It gives you the capacity to explore new markets and take on projects you would have had to refuse with a smaller machine. It’s an investment not just in today’s needs, but in tomorrow’s ambitions.

- Enhanced Product Quality and Consistency Large, industrial-grade extrusion lines are engineered with superior precision and stability. They maintain consistent temperature, pressure, and speed controls across longer production runs. This results in a final product with exceptional uniformity in thickness, colour, and surface finish, batch after batch. High quality builds your brand’s reputation.

- Versatility in Product Range Large lines are often designed to handle a wider range of specifications. They can easily switch between producing different widths, thicknesses, and core materials like fire-retardant grades. This flexibility allows you to cater to diverse customer needs from architectural cladding to industrial partitions without needing multiple machines.

- Cutting-Edge Technology: Kriimpas incorporates into their machines the most recent developments in extrusion Aluminium Plastic Composite Plate This implies that their equipment gives you a competitive edge through improved efficiency, higher-quality products, and lower energy use.

- Complete assistance: Kriimpas offers end-to-end assistance from the time you collaborate with them. This covers every aspect, including initial design and assembly, installation, maintenance, operator Aluminium Plastic Composite Plate and spare part supply. Their knowledgeable support staff is always available to help.

- Customization and Scalability: Your needs are unique. Whether you need a standard line or a highly customized solution for specific panel sizes or special raw material blends, we have the technical capability to design and deliver exactly what you need.

Applications of Aluminium Plastic Composite Plates

1. Building & Construction

- ACP sheets are widely used for exterior wall cladding, façade decoration, and curtain walls.

- Their elegant look, resistance to weather, and easy installation make them perfect for modern architectural designs.

- Builders use them for canopies, column covers, ceilings, and roof edges.

2. Interior Decoration

- In interior spaces, ACP panels enhance beauty and modern appeal.

- Used in wall partitions, false ceilings, modular furniture, and kitchen cabinets.

- Their lightweight structure allows easy handling and creative designs.

3. Signage and Advertising

- ACP sheets provide smooth and printable surfaces for hoardings, signage boards, display panels, and brand name boards.

- They can withstand outdoor exposure, ensuring long-lasting visual impact.

4. Transportation Industry

- Due to their light weight and strength, ACPs are used in vehicle interiors, bus body panels, and train interiors.

- They reduce overall vehicle weight and improve fuel efficiency.

5. Industrial and OEM Applications

- Used as protective covers, machine casings, and industrial enclosures.

- Ideal for clean rooms, laboratories, and healthcare facilities because of their hygiene and corrosion resistance.

6. Renewable Energy and Engineering

- ACP sheets are used as back panels for solar modules and other technical coverings, where rigidity and weather resistance are vital.

Table Specifications of Aluminium Plastic Composite Plate

| Parameter | Specification |

|---|---|

| Material | Aluminium Plastic Composite Plate |

| Sheet Width | 1220mm – 2000mm (customizable) |

| Sheet Thickness | 2mm – 6mm |

| Production Capacity | 400 – 800 kg/hr |

| Line Speed | 3 – 8 m/min |

| Core Material | LDPE / HDPE / Fire-Resistant Core |

| Heating System | PID Controlled Electric / Oil Heating |

| Cooling Method | Multi-Roll Cooling System |

| Power Consumption | 200 – 300 kW (approx.) |

| Line Length | 35 – 45 meters |

| Control System | PLC with Touch Screen Interface |

| Automation Level | Fully Automatic |

| Optional Features | Surface Coating Unit, Embossing, Online Thickness Gauge |

Benefits of Aluminium Plastic Composite Plate

- Superior Bonding Strength and Product Quality: The core of a great ACP sheet is the unbreakable bond between the aluminium and the plastic core. Our advanced laminating technology ensures a perfect, bubble-free bond with exceptional peel strength, giving your sheets the structural integrity demanded by architects and builders.

- High Production Efficiency and Output: Time is money. Our lines are designed for high-speed production, allowing you to meet large market demands efficiently. Automated controls and synchronised systems ensure a smooth, continuous flow from coil to finished, stacked panel.

- Remarkable Energy Efficiency: We integrate energy-saving technologies into our lines, including optimised heating and cooling systems. This significantly reduces your power consumption, lowering your operational costs and improving your bottom line while being kinder to the environment.

- Unparalleled Flexibility for Market Demands: The market is always changing. Our extrusion lines are versatile, allowing you to produce a wide range of products with ease. You can seamlessly switch between different sheet thicknesses, core materials (including standard PE and fire-retardant FR cores), and panel widths, giving you the agility to capture diverse market opportunities.

- Robust and Reliable Engineering: Our lines are built with high-precision components and heavy-duty structures to ensure 24/7 operational reliability with minimal downtime. We believe in building machinery that lasts.

- Expert Local Support: As an India-based company, we provide unparalleled after-sales service. Our team of engineers is readily available for maintenance, spare parts, and technical support, ensuring your business never skips a beat.

- Complete Customization: The market demands variety. With your own line, you can produce any colour, any thickness, any size, and any finish on demand. You can cater to niche markets and offer bespoke solutions that importers simply cannot match quickly or cost-effectively.

- Faster Time-to-Market: When you get a custom order, you don’t have to wait for weeks for a shipment from another country. You can produce and deliver in days, giving you a massive competitive edge.

- A Stronger Brand Identity: By manufacturing your own branded panels, you build a reputation as a manufacturer, not just a trader. This enhances your brand’s credibility and value in the marketplace.

Types of Aluminium Plastic Composite Plate

1. Standard PE Core Extrusion Line

- This is the most common ACP line, using low-density polyethylene (LDPE) or recycled PE as the core material. It’s ideal for producing panels for indoor and outdoor decoration, signage, and partitions.

2. Fire-Retardant (FR) Core Extrusion Line

- For projects that require fire resistance, this line uses mineral-filled FR core materials. It is suitable for high-rise buildings, airports, and public infrastructure.

3. Multi-Layer Co-Extrusion Line

This advanced line allows co-extrusion of multiple plastic layers, combining the benefits of different materials such as HDPE, LDPE, and EVA.

4. High-Speed Automatic Extrusion Line

Designed for large-scale production, this line integrates PLC automation, servo controls, and online thickness gauges for continuous, high-speed operation.

5. Customised ACP Extrusion Line

- At Kriimpas India Pvt. Ltd., we also offer custom-built ACP extrusion lines designed as per client requirements, sheet sizes, and production capacities.

Conclusion

In the production of contemporary materials, the Aluminum Plastic Composite Plate Extrusion Line is revolutionary. It creates premium ACP sheets that are utilized in numerous sectors across the globe by fusing the strength of aluminum with the flexibility of plastic. Architects, designers, and manufacturers now favor ACP panels due to the growing demand for long-lasting and energy-efficient construction materials.

Kriimpas India Pvt. Ltd. is still a top supplier of ACP Extrusion Lines in India and abroad with an emphasis on innovation, dependability, and client satisfaction. Kriimpas India Pvt. Ltd. provides the necessary technology, support, and knowledge to help your business expand, whether you are building a new manufacturing line or modernizing your current one.