Conical Twin Screw Pelletizing Extrusion Line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Efficiency, consistency, and quality are critical success criteria in the contemporary plastic processing sector. The Conical Twin Screw Pelletizing Extrusion Line is one of the most sophisticated and dependable systems in use today. This machine has become a vital component of plastic compounding and recycling operations due to its capacity to create homogenous pellets with great performance characteristics. We at Kriimpas India Pvt. Ltd. are proud to be among the top producers and distributors of Conical Twin Screw Pelletizing Extrusion Lines in India. High productivity, energy efficiency, and a long service life are guaranteed by the precision engineering used in the design of our extrusion systems. We are the best Conical Twin Screw Pelletizing Extrusion Line Manufacturer.

What is a Conical Twin Screw Pelletizing

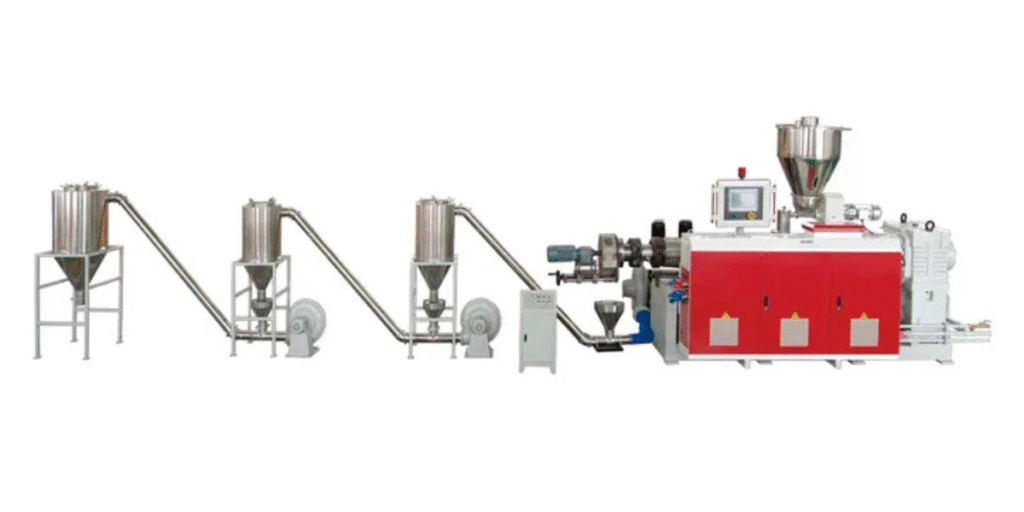

A Conical Twin Screw Pelletizing Extrusion Line is a comprehensive processing system that produces consistent pellets from recycled plastic compounds or raw plastic feedstock. These pellets are subsequently employed in a number of plastic molding techniques, including film extrusion, injection molding, and pipe manufacture. Two conically shaped screws that revolve together in a barrel are part of the mechanism. When compared to a single-screw extruder, the special conical twin-screw design offers superior material mixing, melting, and homogenization. High-quality pellets with consistent density and shape are guaranteed by the system. We are the best Conical Twin Screw Pelletizing Extrusion Line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Unbeatable Economy of Scale This is the most obvious benefit. A larger machine produces a significantly higher volume of pellets per hour. This dramatically reduces your cost per kilogram. You spread your fixed costs like energy, labour, and factory space over a much larger output, leading to a healthier bottom line. It’s the difference between using a car and a freight train to move goods the efficiency at scale is undeniable.

- Enhanced Product Quality and Consistency Larger, high-end extruders are built for stability. Their massive construction and precision engineering dampen vibrations and maintain perfect thermal profiles. This results in exceptional product consistency from the first pellet to the millionth. For critical applications like engineering plastics, optical films, or high-quality masterbatches, this consistency is not a luxury; it’s a requirement.

- Future-Proofing Your Investment The plastic industry is evolving rapidly, with new materials and compounds being developed all the time. A large Krümpas extruder is designed with versatility and power in reserve. It gives you the capability to handle a wider range of materials—from standard polyolefins to challenging engineering plastics and filled compounds—without needing a new machine. You are investing in a platform for future growth and innovation.

- Reduced Operational Complexity Imagine needing to meet a large order with several small machines. You have multiple set-ups, more points of potential failure, and a larger operational team to manage. One large extrusion line simplifies your entire workflow. It centralizes production, reduces manpower requirements per kg of output, and makes process control and quality checks much more straightforward.

- Engineering Excellence and Robust Build: At Kriimpas, we understand that a Conical Twin Screw Pelletizing needs to withstand the rigors of production. Our Conical Twin Screw Pelletizing Extrusion Line are engineered with a focus on durability and performance. We use high-grade materials and precision manufacturing to ensure every component, from the gearbox to the control panel, is built to last, minimizing downtime and maximizing your return on investment.

- Driving Efficiency and Profitability A Kriimpas Conical Twin Screw Pelletizing Extrusion Line is an engine for your profitability. By ensuring superior mixing, we help you reduce raw material costs. Our energy-efficient drives and precise temperature control systems lower your power consumption. Most importantly, the legendary reliability of our machines maximizes your uptime, ensuring you meet your production targets, every time.

- Complete assistance: Kriimpas offers end-to-end assistance from the time you collaborate with them. This covers every aspect, including initial design and assembly, installation, maintenance, operator training, and spare part supply. Their knowledgeable support staff is always available to help.

- Proven Quality & Reliability: Kriimpas India has a reputation for quality and dependability because to years of experience and a track record of successful installations. Our machines are made using premium materials and a rigorous production process to ensure their longevity.

- Competitive Pricing: We think that everyone should have access to high-quality technology. We provide the highest return on your investment by offering reasonable pricing without sacrificing the functionality or quality of our equipment.

Applications of Conical Twin Screw Pelletizing

1. Plastic Pipe Manufacturing

- PVC and PE pellets produced from our extrusion lines are used to make high-quality drainage, water supply, and electrical conduit pipes.

2. Cable and Wire Insulation

- The pellets are used for insulation and sheathing materials in the cable and electrical industry.

3. Plastic Profiles and Sheets

- Pellets are reprocessed to manufacture profiles, panels, and sheets used in construction, furniture, and packaging industries.

4. Injection Molding

- High-quality pellets from our lines are used as feedstock for injection molding applications, creating a wide variety of consumer and industrial products.

5. Film and Packaging

- Pellets can be used to produce thin plastic films and packaging materials, providing flexibility and strength.

6. Masterbatch and Compounding

- Manufacturers of color masterbatches and polymer compounds rely on our lines for uniform dispersion of pigments and fillers.

7. Recycled Plastic Processing

- Our extrusion lines are also used for recycling plastic waste into reusable pellets, supporting sustainable manufacturing practices.

Table Specifications of Conical Twin Screw Pelletizing

| Parameter | Details |

|---|---|

| Material | Conical Twin Screw Pelletizing |

| Screw Diameter | 55/110 mm – 92/188 mm (customizable) |

| Main Motor Power | 22 – 132 kW |

| Output Capacity | 80 – 800 kg/hr |

| Heating Zones | 6 – 10 (depending on model) |

| Cooling Method | Air/Water Cooling |

| Pelletizer Type | Strand or Die-Face Cutter |

| Control System | PLC with HMI Touch Panel |

| Material Compatibility | PVC, CPVC, PE, PP, ABS, and other thermoplastics |

Benefits of Conical Twin Screw Pelletizing

- Superior Mixing and Dispersion: The gradually reducing volume along the screw length creates intense and controlled pressure. This is crucial for breaking down agglomerates and evenly distributing fillers, colors (masterbatch), or other additives throughout the polymer melt. The result? A perfectly homogeneous pellet with consistent color and properties.

- Gentle Yet Efficient Processing: Unlike parallel screws that can generate harsh shear forces, the conical design offers a gentler processing environment. It’s ideal for heat-sensitive materials (like PVC) that might degrade under aggressive conditions, ensuring the polymer’s essential properties are preserved.

- Self-Cleaning and High Output: The intermeshing screws have a self-wiping action, which prevents material from stagnating and degrading inside the barrel. This leads to faster material changeovers, less waste, and higher overall output.

- Energy Efficiency: The conical design requires less torque and power at the output end compared to parallel screw extruders. This translates into significant energy savings, reducing your operational costs and environmental footprint.

- Excellent Degassing: Multiple venting zones along the barrel allow for the effective removal of moisture, air, and volatile components (monomers, solvents) from the melt. This is vital for achieving a high-quality, bubble-free final product with superior mechanical properties.

- Gentle yet Thorough Processing Despite the high shear, the gradual compression of a conical screw is often gentler on heat-sensitive materials. It prevents localized overheating or material degradation, preserving the polymer’s essential properties. This makes it ideal for a wide range of materials, from PVC to specialty engineering plastics.

- Robustness and Longer Lifespan The root diameter of the conical screws increases towards the discharge end, making them incredibly strong and rigid at the point of highest pressure. This robust construction leads to less wear and tear, reduced maintenance downtime, and a significantly longer service life for the critical components.

- Enhanced Degassing and Venting Many compounding processes require the removal of moisture, air, or volatile by-products a process called devolatilization). The conical screw’s design creates a larger surface area in the venting zone, allowing for more effective removal of these volatiles. This is crucial for producing high-clarity products or materials sensitive to moisture, like engineering plastics.

- Lower Energy Consumption This is a major operational benefit. The tapered screws require less torque and power at the discharge end, where the material is already molten and compressed. This translates to significant energy savings, reducing your per-kilogram production cost and making your process more sustainable.

Types of Conical Twin Screw Pelletizing

1. PVC Conical Twin Screw Pelletizing Line

- This type is designed specifically for PVC (Polyvinyl Chloride) compounding and pelletizing. It ensures uniform plasticization, excellent color mixing, and smooth surface finish.

- Applications: PVC pipes, cables, profiles, and films.

2. WPC Conical Twin Screw Pelletizing Line

This line is suitable for Wood Plastic Composite (WPC) materials. It can process a combination of plastic resins and wood fibers to produce durable and eco-friendly composite pellets.

Applications: Decking, furniture, and building materials.

3. CPVC Conical Twin Screw Pelletizing Line

- The CPVC (Chlorinated PVC) extrusion line is used for high-temperature applications. It offers better resistance to heat and corrosion compared to standard PVC lines.

- Applications: Hot water pipes and industrial fittings.

4. Soft and Rigid PVC Pelletizing Line

- This machine can handle both soft and rigid PVC materials. It provides excellent flexibility in production and consistent pellet quality.

- Applications: Hoses, insulation, and profiles.

5. High-Filler Compounding Pelletizing Line

- For industries using high filler content (like calcium carbonate or talc), this line is designed with enhanced torque and mixing capabilities to maintain product uniformity.

- Applications: Masterbatch and filler compound production.

Conclusion

The plastic processing industry has undergone a transformation thanks to the Conical Twin Screw Pelletizing Extrusion Line, which combines high efficiency, precision, and adaptability. This technique guarantees optimal productivity and uniform pellet quality whether you are manufacturing PVC compounds, WPC granules, or recycling plastics.

We at Kriimpas India Pvt. Ltd. are pleased to be among the top producers of Conical Twin Screw Pelletizing Extrusion Lines, offering cutting-edge solutions to customers in India and elsewhere. Our equipment is designed for sustainability, performance, and durability, enabling your company to expand with assurance.