PP Honeycomb Plate Extrusion Line Provider

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

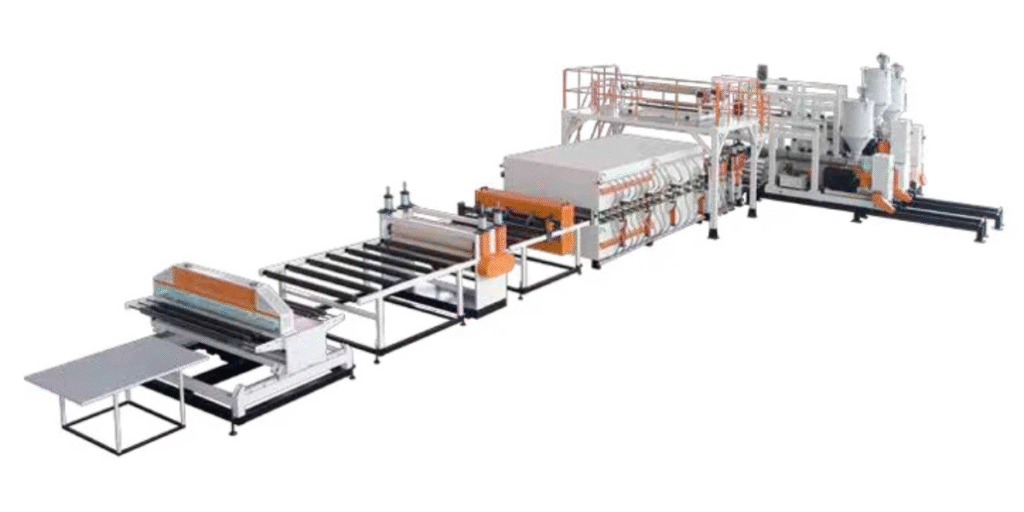

In today’s industrial environment, manufacturing operations’ performance is determined by their efficiency, inventiveness, and dependability. The manufacturing of PP honeycomb plates is one such crucial business. Because of its lightweight design, great strength, and environmentally benign nature, these plates are utilized extensively in furniture, construction, automotive, and packaging industries. The PP Honeycomb Plate Extrusion Line, a complex equipment configuration that guarantees consistent performance and high-quality output, is at the center of this manufacturing. As a leading supplier of PP Honeycomb Plate Extrusion Line, Kriimpas India Pvt. Ltd. distinguishes itself by providing state-of-the-art technology, personalized solutions, and unparalleled support. We are the best PP Honeycomb Plate Extrusion Line Supplier.

What is a PP Honeycomb Plate Extrusion Line

A PP Honeycomb Plate is a polypropylene sheet that is both lightweight and robust. Its distinctive honeycomb structure offers superior durability, impact resistance, and strength-to-weight ratio. These plates are frequently utilized inPP honeycomb plates are becoming more and more popular because of their affordability, environmental friendliness, and adaptability. Because of this, there is a need for dependable and effective extrusion lines that can produce plates of superior quality. We are the best PP Honeycomb Plate Extrusion Line Manufacturer.

Why Choose Kriimpas India Pvt. Ltd

- Unmatched Performance and Quality: We are dedicated to providing long-lasting machinery. The newest technology and highest-grade raw materials are used in the careful engineering of our PP Honeycomb Plate Extrusion Line. Our commitment to quality guarantees that our products meet and beyond the most exacting industry standards, giving you dependable, highly productive, and energy-efficient machinery. Our utilization of cutting-edge control systems gives you a competitive edge by guaranteeing accurate and reliable manufacturing.

- Tailored Solutions to Meet Your Needs: We are aware that there is no one-size-fits-all solution. We can develop and construct a system that is precisely suited to your unique needs, regardless of how big or little your business is. We provide a wide range of solutions for different materials and production needs, including single-screw and PP Honeycomb Plate Extrusion Line as well as a variety of downstream equipment. We can assist you in developing a unique solution that fits your spending limit and particular requirements.

- Comprehensive After-Sales Support: After the sale, our partnership with you continues. We take great satisfaction in offering comprehensive and prompt after-sales support. Our committed staff is always on hand to make sure your manufacturing line runs efficiently, from installation and training to maintenance and spare parts. Our local presence in Gujarat reduces downtime and increases your profitability by enabling quicker response times and a deeper comprehension of the local market.

- Innovation and Dependability: To remain at the forefront of PP Honeycomb Plate Extrusion Line technology, we consistently engage in research and development. Our emphasis on innovation enables us to provide equipment that are easy to use and maintain in addition to being effective and productive. You are investing in a machine that is designed for the future when you choose Kriimpas.

- Our Standard is Customization: You have particular needs. Our extrusion lines may be tailored to match your precise product requirements, whether you need to create panels with a particular thickness, cell size, or width, or you wish to use special skin materials. Together, we construct the machine that manufactures your goods.

- Deep-Rooted Expertise and Experience: We have spent years specializing in plastic extrusion technology. Our team of engineers understands the nuances of polymer behaviour and machine design. This experience translates into extrusion lines that are not just built, but engineered for excellence, ensuring consistent, high-quality honeycomb panel production day in and day out.

- Cutting-Edge Technology: Kriimpas incorporates into their machines the most recent developments in extrusion PP Honeycomb Plate Extrusion Line. This implies that their equipment gives you a competitive edge through improved efficiency, higher-quality products, and lower energy use.

- Complete assistance: Kriimpas offers end-to-end assistance from the time you collaborate with them. This covers every aspect, including initial design and assembly, installation, maintenance, operator PP Honeycomb Plate Extrusion Line and spare part supply. Their knowledgeable support staff is always available to help.

- Proven Quality & Reliability: Kriimpas India has a reputation for quality and dependability because to years of experience and a track record of successful installations. Our machines are made using premium materials and a rigorous production process to ensure their longevity.

- Competitive Pricing: We think that everyone should have access to high-quality technology. We provide the highest return on your investment by offering reasonable pricing without sacrificing the functionality or quality of our equipment.

Applications of PP Honeycomb Plate Extrusion Line

1. Construction Industry

- PP honeycomb panels are widely used in interior partitions, false ceilings, and wall panels. Their lightweight nature reduces structural load, while the honeycomb design provides excellent strength and insulation properties.

2. Automotive and Transportation

- The automotive industry uses PP honeycomb plates for floor panels, doors, and trunk liners, thanks to their high strength-to-weight ratio. These panels help reduce vehicle weight, improving fuel efficiency and performance.

3. Furniture Industry

- Lightweight honeycomb panels are ideal for modular furniture, office partitions, and display boards, providing durability without adding unnecessary weight.

4. Packaging Industry

- PP honeycomb sheets are increasingly used in protective packaging and pallets. Their shock-absorbing properties and strength make them perfect for transporting delicate or heavy items safely.

5. Marine Industry

- Due to their water-resistant and corrosion-free nature, PP honeycomb panels are suitable for boat interiors and decking. They offer longevity even in harsh marine environments.

6. Cleanroom Applications

- Industries such as pharmaceuticals, electronics, and healthcare use honeycomb panels in cleanroom partitions due to their hygiene-friendly and lightweight characteristics.

7. Automotive Industry

- PP honeycomb plates are widely used in automotive interiors for doors, floors, dashboards, and trunk panels. Their lightweight nature helps reduce vehicle weight, improving fuel efficiency. Additionally, their impact resistance and durability enhance safety and longevity.

8. Signage & Display Panels

- The plates are ideal for advertising boards, exhibition panels, and display structures. Their smooth surface allows easy printing, and their rigidity ensures the panels remain durable and stable over time.

Table of Specifications PP Honeycomb Plate Extrusion Line

| Parameter | Specification |

|---|---|

| Material | PP Honeycomb Plates |

| Production Capacity | 500–1500 kg/h |

| Honeycomb Sheet Width | 1200–2400 mm |

| Sheet Thickness | 3–15 mm |

| Die Type | Flat Die / Honeycomb Die |

| Cooling Method | Water Cooling / Air Cooling |

| Main Motor Power | 55–110 kW |

| Heating Method | Electric / Oil Heater |

| Control System | PLC Automatic Control |

| Material Compatibility | PP, PE, recycled PP |

Benefits of PP Honeycomb Plate Extrusion Line

- Superior Product Quality and Versatility: A machine is only as good as the product it produces. With a Kriimpas extrusion line, you can produce PP honeycomb boards with perfect cell structure, excellent surface finish, and consistent thickness. This high quality makes your products more competitive in the market. Furthermore, our lines are versatile, allowing you to produce panels of different thicknesses and sizes to cater to various customer needs.

- Comprehensive Technical Support and Training: We believe the journey starts after the installation. Our team of expert engineers provides complete installation, commissioning, and hands-on training for your staff. We ensure your team is confident in operating and performing basic maintenance on the line.

- Reliable After-Sales Service and Spare Parts: Downtime is our enemy too. Kriimpas has a robust after-sales service network and maintains a ready inventory of critical spare parts. Our prompt service ensures that if any issues arise, they are resolved with minimal disruption to your production schedule.

- End-to-End Expertise: We provide complete turnkey projects. From plant layout and machinery installation to comprehensive operator training and ongoing technical support, we are with you at every step, ensuring a smooth and successful start to your production journey.

- Robust & Reliable Engineering: Our extrusion lines are built with durability and precision in mind. We use high-quality components and robust engineering practices to ensure your line operates with minimal downtime and maximum efficiency, day in and day out, even in demanding production environments.

- High Output & Superior Product Quality: Our lines are designed for high productivity, producing consistent, top-quality honeycomb panels with excellent surface finish and structural integrity. This allows you to meet large order demands and build a reputation for quality in the marketplace.

- Energy-Efficient Design: We understand that operational costs are a major concern. Our systems are engineered for optimal energy consumption, helping you reduce your power bills and improve your overall profit margins while reducing your carbon footprint.

- Customizable Solutions: We know that one size does not fit all. We work closely with you to understand your specific production goals and can customize the extrusion line to suit your unique requirements, whether you are a startup or a large-scale manufacturer.

- Amazing Customization and Versatility: Variety is what the market wants. Our extrusion lines may be tailored to your exact specifications, whether you need to create thick, dense cores for heavy-duty construction panels or thin cores for signage. Our flexible sheet width, cell size, and core density options let you expand into new markets and vary your product line.

Types of PP Honeycomb Plate Extrusion Lines

1. Single Layer Extrusion Line

- This is the most basic type of extrusion line, producing a single honeycomb sheet layer. It is ideal for small-scale production and is cost-effective.

- Applications: Packaging materials, furniture cores, and light-duty construction boards.

2. Double Layer Extrusion Line

- As the name suggests, it produces honeycomb sheets with two layers, offering higher strength and durability. This type is suitable for industrial applications requiring moderate to high strength.

3. Multi-Layer Extrusion Line

- This is the most advanced type, capable of producing honeycomb sheets with multiple layers for maximum strength and insulation. It is highly suitable for large-scale manufacturing and high-demand industries.

4. Customized Extrusion Lines

- Kriimpas India Pvt. Ltd also provides custom-designed PP honeycomb plate extrusion lines tailored to specific production capacities, sheet thicknesses, and industrial requirements.

5 Large PP Honeycomb Plate

- Large-sized plates are increasingly in demand for industrial and construction applications. They are perfect for walls, floors, and large furniture pieces. Their larger surface area reduces the number of joints required, improving efficiency and aesthetics.

Conclusion

In conclusion, producers looking to create premium, lightweight panels for a range of industries are finding that the PP honeycomb plate extrusion line is revolutionary. It has become a vital tool for contemporary production units due to its many benefits, which include cost-effectiveness, efficiency, and versatility.

Selecting Kriimpas India Pvt. Ltd. as your PP Honeycomb Plate Extrusion Line Provider guarantees that you will have access to state-of-the-art technology, customized solutions, and knowledgeable assistance, all of which will help your company expand and prosper in a cutthroat industry. Our extrusion line enables you to manufacture excellent PP honeycomb panels that satisfy the highest standards, regardless of your industry.