Parallel Twin Screw Pelletizing Extrusion Line

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

Efficiency, accuracy, and product quality are more crucial than ever in the modern plastics industry. The Parallel Twin Screw Pelletizing Extrusion Line is one device that has revolutionized the way plastics are processed by manufacturers. This technology, which is well-known for its high output, adaptability, and consistency, has proven essential for many companies looking to streamline their manufacturing procedures. Modern Parallel Twin Screw Pelletizing Extrusion Lines that are tailored to the requirements of both small and large industries are our specialty at Kriimpas India Pvt. Ltd. Our machines are designed to provide long-term dependability, consistent quality, and exceptional performance. We are the best Parallel Twin Screw Pelletizing Extrusion Line Manufacturer.

What is a Parallel Twin Screw Pelletizing Extrusion Line

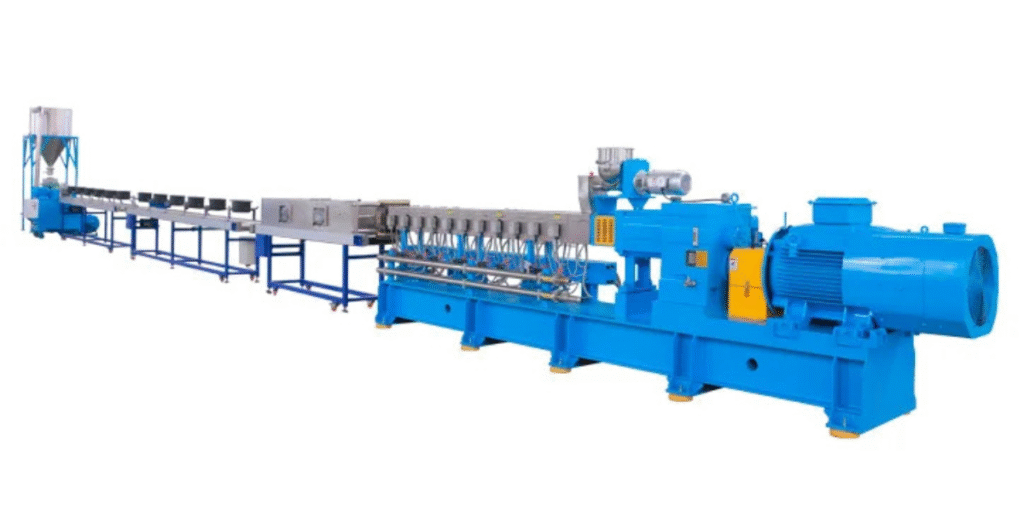

A particular kind of extrusion machinery used to process polymers and turn them into homogeneous pellets is a Parallel Twin Screw Pelletizing Extrusion Line. Twin screw systems, as opposed to single screw extruders, include two intermeshing screws positioned inside a barrel parallel to one another. Better mixing, accurate temperature control, and effective processing of a variety of materials are made possible by this design. We are the best Parallel Twin Screw Pelletizing Extrusion Line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Uncompromising Build Quality and Reliability: A machine is only as good as its components. At Kriimpas, we use robust, high-grade materials and partner with world-class component suppliers. Our focus on rugged construction and precision engineering means our extrusion lines are built for the demanding environment of production, ensuring maximum uptime and a long, productive lifecycle for your investment.

- Customization and Deep Domain Expertise: We recognize that no two manufacturing problems are same. Are you using a special ceramic blend, biodegradable polymers, or reinforced nylons In order to comprehend your material, your intended output, and your quality standards, our engineering team works closely with you. After that, we modify the extrusion line to make sure it is precisely tailored for your particular application, including the downstream equipment, screw configuration, and barrel design.

- Engineering Excellence and Robust Build: At Kriimpas, we understand that a pelletizing line needs to withstand the rigors of production. Our extrusion lines are engineered with a focus on durability and performance. We use high-grade materials and precision manufacturing to ensure every component, from the gearbox to the control panel, is built to last, minimizing downtime and maximizing your return on investment.

- Driving Efficiency and Profitability A Kriimpas extrusion line is an engine for your profitability. By ensuring superior mixing, we help you reduce raw material costs. Our energy-efficient drives and precise temperature control systems lower your power consumption. Most importantly, the legendary reliability of our machines maximizes your uptime, ensuring you meet your production targets, every time.

- Innovation and Dependability: To remain at the forefront of Parallel Twin Screw Pelletizing Extrusion Line processing technology, we consistently engage in research and development. Our emphasis on innovation enables us to equipment that are easy to use and maintain in addition to being effective and productive. You are investing in a machine that is designed for the future when you choose Kriimpas.

- Cutting-Edge Technology: Kriimpas incorporates into their machines the most recent developments in extrusion Parallel Twin Screw Pelletizing Extrusion Line. This implies that their equipment gives you a competitive edge through improved efficiency, higher-quality products, and lower energy use.

- Complete assistance: Kriimpas offers end-to-end assistance from the time you collaborate with them. This covers every aspect, including initial design and assembly, installation, maintenance, operator training, and spare part supply. Their knowledgeable support staff is always available to help.

- Proven Quality & Reliability: Kriimpas India has a reputation for quality and dependability because to years of experience and a track record of successful installations. Our machines are made using premium materials and a rigorous production process to ensure their longevity.

- Competitive Pricing: We think that everyone should have access to high-quality technology. We provide the highest return on your investment by offering reasonable pricing without sacrificing the functionality or quality of our equipment.

Applications of Parallel Twin Screw Pelletizing Extrusion Lines

1. Plastic Pellet Manufacturing

- The primary function of a twin screw extrusion line is to produce high-quality plastic pellets. These pellets serve as raw materials for injection molding, blow molding, and other plastic manufacturing processes. Uniform pellet size ensures smooth feeding and consistent product quality.

2. Compounding of Polymers

- In compounding, raw polymers are mixed with additives, fillers, stabilizers, or colorants to create customized formulations. The parallel twin screw extrusion line ensures thorough dispersion of all components, resulting in high-performance compounded materials suitable for specialized applications like automotive parts, packaging films, and electrical insulation.

3. Recycling of Plastics

- With the growing emphasis on sustainability, plastic recycling has become crucial. Twin screw extruders are widely used to recycle post-consumer plastics by reprocessing them into reusable pellets. This process reduces plastic waste and promotes environmentally friendly manufacturing practices.

4. Masterbatch Production

- Masterbatches are concentrated mixtures of pigments or additives that are blended with base polymers to achieve desired properties. Parallel twin screw extrusion lines provide consistent mixing and uniform dispersion, which is critical for producing high-quality masterbatches.

5. Specialty Applications

- These extrusion lines are also used in advanced applications like bio-plastic production, PVC compounding, and engineering polymers, where precise temperature control and high mixing efficiency are essential.

6. Food and Feed Industry

- Beyond plastics, twin screw pelletizing extrusion lines are also used in the food and feed industry. They help in producing pet food, aquafeed, and snack pellets by mixing ingredients, cooking, and pelletizing in a single process.

7. Recycling Industry

- With increasing environmental concerns, recycling plastics has become critical. Parallel twin screw extruders are used for reprocessing plastic waste into reusable pellets, helping industries move towards sustainable production practices.

Specifications Table of Parallel Twin Screw Pelletizing Extrusion Line

| Feature | Specification |

|---|---|

| Material | Twin Screw Pelletizing Extrusion Line |

| Output Capacity | 400–800 kg/h |

| Screw Speed | 200–600 RPM |

| Screw Length/Diameter Ratio | 40:1 |

| Main Motor Power | 90 kW |

| Heating Zones | 5 zones |

| Cooling System | Water cooling with stainless steel tank |

| Control System | Siemens PLC with HMI interface |

| Pelletizer Type | Water-ring pelletizer with adjustable speed |

| Power Supply | 380V, 50Hz, 3-phase |

Benefits of Twin Screw Pelletizing Extrusion Line

- Superior Mixing and Dispersion: Think of trying to mix cocoa powder perfectly into milk. A spoon single-screw can stir, but a high-speed blender twin screw creates a perfectly homogenous mixture. The twin-screw action provides intense shear and mixing, ensuring fillers, colors, and additives are distributed evenly throughout the polymer. This is critical for achieving consistent product quality, batch after batch.

- Exceptional Flexibility and Versatility: This is a major win for businesses. A single parallel twin-screw extruder can handle a wide range of recipes and materials. You can switch from one formulation to another with minimal downtime. Whether you’re working with sensitive PVC, engineering plastics, or biodegradable compounds, this machine can be configured to handle it gently or aggressively, as needed.

- High Torque and Power: The parallel design allows for robust gearboxes that can deliver very high torque. In simple terms, this means the screws are strong enough to push through tough, highly viscous materials without stalling. This power ensures you can run at higher outputs and tackle challenging recipes that other machines can’t handle.

- Precise Temperature Control: The entire barrel of the extruder is divided into multiple heating and cooling zones. This allows for incredibly precise control over the temperature profile along the entire length of the screws. For materials that are sensitive to heat, this precision is the difference between a perfect pellet and a degraded product.

- Self-Cleaning Action: The intermeshing screws have a wonderful self-wiping characteristic. As they turn, they clean each other. This reduces material hang-up and contamination when you change colors or formulations, leading to less waste and faster product changeovers.

- Enhanced Degassing and Devolatilization: Many processes involve removing moisture, solvents, or other volatile components. The twin-screw design allows for the creation of venting zones along the barrel. Under a vacuum, these vents efficiently pull out unwanted volatiles, resulting in a purer, higher-quality final pellet.

- Flexibility is King: This is its biggest advantage. You can process a vast range of materials with different viscosities and recipes. Want to switch from a simple polypropylene to a complex flame-retardant compound? A twin-screw extruder can handle it with minimal downtime.

- Perfect Heat Control: The machining process generates heat. Twin-screw extruders offer excellent control over this temperature profile along the entire barrel length. This is critical for heat-sensitive materials that could degrade if overheated.

Types of Twin Screw Pelletizing Extrusion Line

1. Co-Rotating Parallel Twin Screw Extruder

- In a co-rotating twin screw extruder, both screws rotate in the same direction. This design ensures excellent mixing and compounding capabilities. Co-rotating extruders are ideal for high-viscosity materials and complex formulations. They are widely used in PVC, masterbatch production, and polymer blends.

2. Counter-Rotating Parallel Twin Screw Extruder

- In a counter-rotating design, the screws rotate in opposite directions. This type is ideal for processing low-viscosity materials and achieving gentle mixing without degrading sensitive materials. It is often used for thermoplastics and heat-sensitive polymers.

3. Ventilation or Degassing Extrusion Line

- Some parallel twin screw extruders are equipped with a degassing system that removes trapped air and moisture from the polymer melt. This ensures higher quality pellets with fewer defects. Degassing lines are commonly used in PVC, recycled plastics, and specialty polymer applications.

4. High-Output Pelletizing Lines

- These are designed for large-scale industrial production. With advanced automation, high-speed pelletizers, and long extruder barrels, high-output lines can produce tons of pellets per day while maintaining consistent quality.

5. Customized Twin Screw Pelletizing Lines

- Every industry has unique requirements. At Kriimpas India Pvt. Ltd, we offer tailor-made extrusion lines that cater to specific materials, output capacities, and pellet specifications. Our expert engineers work closely with clients to design systems that optimize production efficiency and reduce operational costs.

Conclusion

With its unparalleled efficiency, accuracy, and adaptability, the Parallel Twin Screw Pelletizing Extrusion Line is revolutionizing the plastics manufacturing sector. With features like automated control, energy economy, and constant pellet quality, this technology makes it easy for producers to meet the needs of contemporary manufacturing.

Selecting a reliable partner like Kriimpas India Pvt. Ltd guarantees that you will have access to cutting-edge equipment, knowledgeable assistance, and solutions that are specifically designed to meet your production needs. Our extrusion lines provide excellent performance and long-term dependability whether you’re recycling plastics, compounding polymers, or making masterbatches.