Technical Polymer Extrusion Line Provider

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

In today’s constantly changing industrial environment, the need for high-quality polymer goods is increasing tremendously. One of the primary technologies fueling this need is polymer extrusion, which is widely used to make plastic components for the automotive, construction, packaging, and electrical industries. Choosing the proper Technical Polymer Extrusion Line Provider is crucial for businesses that want dependability, efficiency, and excellent performance. We are the best Technical Polymer Extrusion Line Manufacturer.

Kriimpas India Pvt. Ltd. distinguishes out among the industry leaders as a reliable partner for cutting-edge polymer extrusion solutions.If your company relies on polymer processing, selecting the correct extrusion line provider can mean a big difference in terms of quality, efficiency, and profitability. In this article, we will discuss what polymer extrusion is, why technical extrusion lines are important, and how Kriimpas India Pvt. Ltd., a reputable Technical Polymer Extrusion Line Provider, may be your ideal growth partner.

What is Technical Polymer Extrusion Line

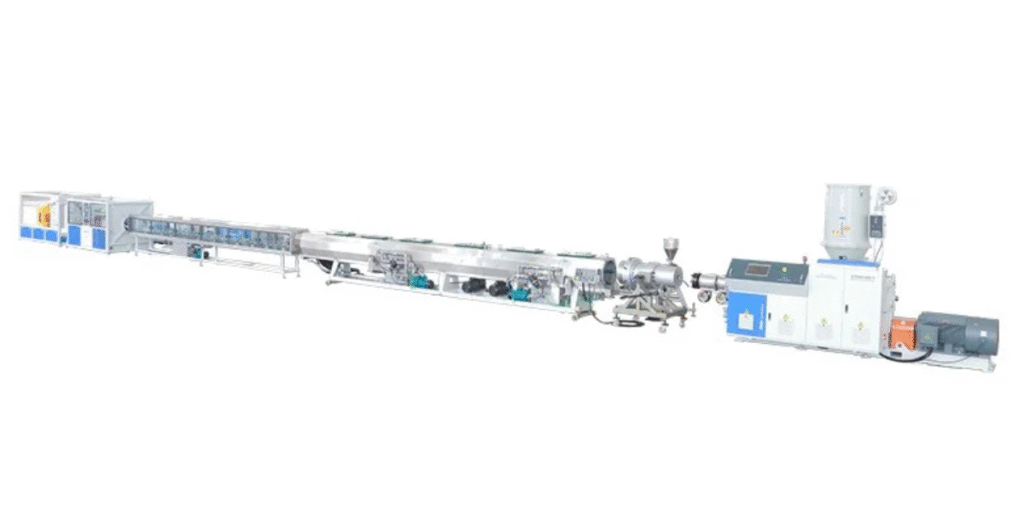

Polymer extrusion is the process of melting raw plastic materials (polymers) and shaping them into continuous profiles such as pipes, sheets, tubes, wires, films, and other products. This technique is frequently utilized in a variety of sectors since it guarantees. An extrusion line is more than just one machine; it is a comprehensive setup that includes the extruder, die, cooling unit, haulage system, and cutting equipment. The quality and performance of the extrusion line have a direct impact on the quality of the finished product. That is why selecting the appropriate provider is crucial. We are the best Technical Polymer Extrusion Line Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Unmatched Performance and Quality: We are dedicated to providing long-lasting machinery. The newest technology and highest-grade raw materials are used in the careful engineering of our Technical Polymer Extrusion Line. Our commitment to quality guarantees that our products meet and beyond the most exacting industry standards, giving you dependable, highly productive, and energy-efficient machinery. Our utilization of cutting-edge control systems gives you a competitive edge by guaranteeing accurate and reliable manufacturing.

- Tailored Solutions to Meet Your Needs: We are aware that there is no one-size-fits-all solution. We can develop and construct a system that is precisely suited to your unique needs, regardless of how big or little your business is. We provide a wide range of solutions for different materials and production needs, including single-screw and twin-screw extruders as well as a variety of downstream equipment. We can assist you in developing a unique solution that fits your spending limit and particular requirements.

- Comprehensive After-Sales Support: After the sale, our partnership with you continues. We take great satisfaction in offering comprehensive and prompt after-sales support. Our committed staff is always on hand to make sure your manufacturing line runs efficiently, from installation and training to maintenance and spare parts. Our local presence in Gujarat reduces downtime and increases your profitability by enabling quicker response times and a deeper comprehension of the local market.

- Innovation and Dependability: To remain at the forefront of polymer processing technology, we consistently engage in research and development. Our emphasis on innovation enables us to provide equipment that are easy to use and maintain in addition to being effective and productive. You are investing in a machine that is designed for the future when you choose Kriimpas.

- Cutting-Edge Technology: Kriimpas incorporates into their machines the most recent developments in extrusion technology. This implies that their equipment gives you a competitive edge through improved efficiency, higher-quality products, and lower energy use.

- Complete assistance: Kriimpas offers end-to-end assistance from the time you collaborate with them. This covers every aspect, including initial design and assembly, installation, maintenance, operator training, and spare part supply. Their knowledgeable support staff is always available to help.

- Proven Quality & Reliability: Kriimpas India has a reputation for quality and dependability because to years of experience and a track record of successful installations. Our machines are made using premium materials and a rigorous production process to ensure their longevity.

- Full After-Sales Support: After the sale, our partnership with you continues. We offer comprehensive post-purchase assistance, which includes installation, employee training, timely maintenance, and replacement parts. We want your production to continue operating smoothly and effectively for many years to come.

- Competitive Pricing: We think that everyone should have access to high-quality technology. We provide the highest return on your investment by offering reasonable pricing without sacrificing the functionality or quality of our equipment.

Applications of Technical Polymer Extrusion Line

1. Automotive Industry

- Technical polymer extrusion lines are crucial for producing lightweight yet durable automotive parts. This includes sealing strips, cable conduits, fuel lines, and interior trim. Polymers like PVC and TPE are commonly used for these applications, providing resistance to heat, abrasion, and chemicals.

2. Construction Industry

- Extruded polymer profiles are widely used in construction. PVC pipes, window frames, door seals, and cable conduits are just a few examples. The durability, weather resistance, and low maintenance of these products make them ideal for residential and commercial construction.

3. Medical and Pharmaceutical Industry

- The precision of technical polymer extrusion lines enables the production of medical-grade tubing, catheters, and packaging materials. Using high-quality polymers like silicone and TPE ensures biocompatibility, flexibility, and safety for healthcare applications.

4. Electrical and Electronics Industry

- Polymer extrusion lines produce insulating materials, cable jackets, and protective tubing for electrical and electronic components. With the growing demand for electronics, extrusion technology ensures high-performance products that meet strict safety standards.

5. Packaging Industry

- Plastic films, sheets, and flexible packaging materials are often manufactured using extrusion technology. These materials are used in food packaging, industrial wraps, and consumer goods packaging, offering strength, flexibility, and barrier properties.

6. Medical Industry

- In healthcare, polymers are used to manufacture tubing, catheters, IV lines, and flexible connectors. Kriimpas extrusion lines provide clean and precise extrusion solutions that comply with strict medical standards.

7. Plastic Profiles

- Extruded plastic profiles find applications in windows, doors, furniture, and automotive parts. Kriimpas India Pvt. Ltd offers extrusion lines capable of producing complex profiles with smooth finishes and uniform dimensions.

8. Films and Sheets

- The packaging, agricultural, and construction industries heavily rely on plastic films and sheets. The company’s technical polymer extrusion lines ensure consistent thickness, high clarity, and superior strength for various sheet and film products.

Table of SpecificationTechnical Polymer Extrusion Line

| Parameter | Specification |

|---|---|

| Material | Polymer Extrusion Lines |

| Screw Diameter | 45 mm – 120 mm |

| Output Capacity | 50 kg/hr – 500 kg/hr |

| Temperature Control | ±1°C precision |

| Die Type | Custom-designed for sheets, films, or pipes |

| Cooling System | Air-cooled / Water-cooled options |

| Control Panel | PLC-based automatic control |

| Power Requirement | 15 kW – 150 kW |

| Material Compatibility | PVC, PE, PP, PET, Engineering Polymers |

| Optional Accessories | Melt filters, vacuum calibration, online thickness gauges |

Advantage of Technical Polymer Extrusion Line

- Advanced Technology: Kriimpas specializes in efficient twin-screw extruders, which are especially important when processing heat-sensitive materials such as PVC. These extruders deliver excellent mixing while using less power, resulting in higher production and more energy efficiency. Their equipment frequently integrate intelligent control systems that provide precision, ease of use, and consistent production.

- Superior Quality and Durability: Kriimpas’s machines are built to last. They use high-grade materials and are engineered for low maintenance and high performance, giving you a return on investment that extends well into the future.

- Customization and Expertise: Every project is unique. Kriimpas understands this and offers tailored solutions to meet specific production requirements. Whether you need to produce a particular type of pipe, profile, or sheet, their team of experts works with you from design to installation and ongoing support.

- Reliable Support and Service: A machine is only as good as the support behind it. Kriimpas is known for its customer-centric approach, providing reliable after-sales service and technical assistance. They have a proven track record of helping businesses streamline their production processes and achieve their goals efficiently.

- Commitment to Quality: We believe in delivering excellence. Our machinery is meticulously engineered using premium quality raw materials and undergoes stringent quality checks to ensure durability, reliability, and long service life.

- High Volume & Continuous Production: Unlike other methods that make one item at a time, extrusion is a continuous process. As long as you feed it raw material, it keeps producing. This makes it perfect for large-scale, high-volume manufacturing.

- Cost-Effectiveness: The ability to run continuously, along with minimal labor requirements due to automation, significantly reduces the cost per unit. Plus, modern lines can easily recycle and reuse any scrap material, cutting down on waste and raw material costs.

- Versatility: Extrusion lines are incredibly flexible. By simply changing the die and adjusting a few settings, you can produce a wide range of products, including pipes, sheets, films, and various complex profiles for things like window frames or automotive parts.

- Superior Quality Control: Modern lines are equipped with advanced sensors and control systems that monitor things like temperature, pressure, and speed in real-time. This allows for precise adjustments on the fly, ensuring every single product meets the highest quality standards. This level of control results in products with consistent dimensions, uniform thickness, and fewer defects.

- Energy Efficiency: The latest extrusion lines are designed to be more energy-efficient. They use advanced heaters and motors that only use the power they need, which is not only good for the planet but also helps cut down on operating costs.

Types of Technical Polymer Extrusion Lines

1. Single Screw Extrusion Line

- Single screw extrusion lines are widely used in processing thermoplastics. They are suitable for producing pipes, sheets, films, and profiles. These lines offer reliable performance, easy operation, and low maintenance, making them ideal for small to medium-scale production.

2. Twin Screw Extrusion Line

- Twin screw extruders are designed for high-performance processing. They handle complex polymers, composite materials, and specialty compounds. Twin screw extrusion lines offer better mixing, uniformity, and higher output, making them perfect for industries like automotive, medical, and packaging.

3. Pipe Extrusion Line

- Pipe extrusion lines are specifically designed to manufacture plastic pipes for water supply, sewage, gas, and industrial applications. Kriimpas India Pvt. Ltd provides pipe extrusion lines capable of producing different diameters and thicknesses, ensuring quality and durability.

4. Sheet and Film Extrusion Line

- Sheet and film extrusion lines produce polymer sheets and films used in packaging, construction, and consumer products. These lines provide high precision and uniform thickness, ensuring smooth surfaces and superior quality.

5. Profile Extrusion Line

- Profile extrusion lines manufacture polymer profiles used in construction, furniture, and automotive applications. These lines allow the production of customized shapes with high accuracy and surface finish.

6. Specialty Extrusion Line

- Kriimpas India Pvt. Ltd also offers specialty extrusion lines for advanced polymer products such as medical tubing, high-strength composites, and functional films. These lines are engineered for specific applications and can be tailored according to customer requirements.

Conclusion

In today’s competitive market, having the correct machinery can mean the difference in the polymer production sector. Kriimpas India Pvt. Ltd has established itself as a dependable and trustworthy Technical Polymer Extrusion Line Provider, providing sophisticated, effective, and tailored solutions to organizations of all sizes. Kriimpas guarantees outstanding quality, consistency, and performance for PVC pipes, automotive components, packaging materials, and industrial profiles.

Companies that engage with Kriimpas India Pvt. Ltd not only invest in cutting-edge technology, but they also receive a long-term ally dedicated to growth, innovation, and quality. Kriimpas India Pvt. Ltd. remains the go-to provider for technical polymer extrusion plants in India and elsewhere.