Vibro feeders Provider in India

Table of Contents

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers.

The industrial landscape of India is characterized by a wide array of operations, ranging from the enormous mining sector to the complex realm of food processing, the robust construction industry to the exacting standards of pharmaceuticals. Vibro feeders, which are often not visible but vital, lie at the heart of many of these processes, allowing for smooth, controlled, and efficient movement of materials. We are the best Vibro feeders Manufacturer.

These extraordinary devices utilize the power of vibration to control the movement of bulk materials, converting inconsistent feeding into a smooth, automated operation.This article examines the crucial function of vibro feeders in the industrial development of India, investigating their working mechanisms, common uses, and the unique benefits of collaborating with a premier Vibro Feeders Provider in India such as Kriimpas India Pvt. Ltd.

Understanding the Vibro feeders

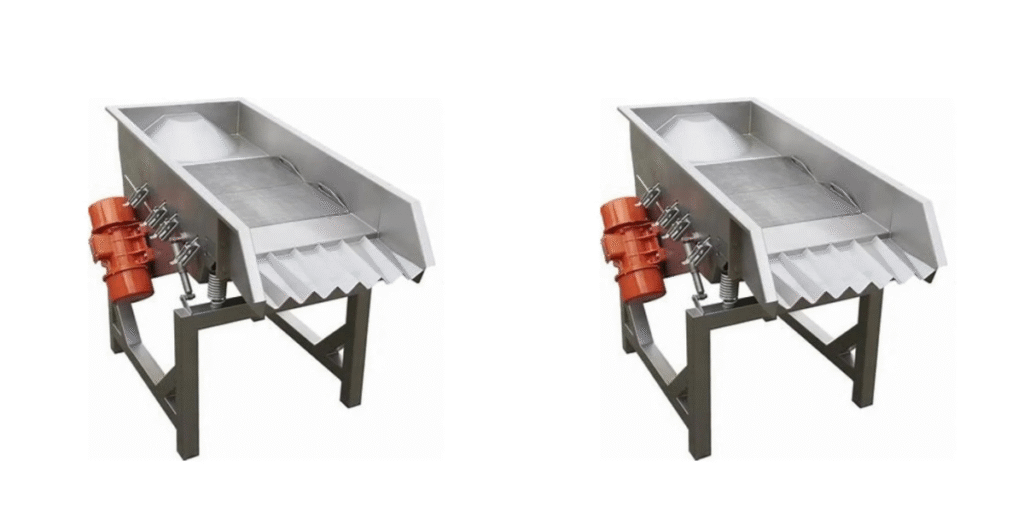

The basic operating principle consists of a feeder trough or pan mounted on springs, along with a drive unit that produces controlled vibrations. These vibrations usually comprise both horizontal and vertical elements. Upon activation of the feeder, the material on the trough undergoes a sequence of micro-hops or slides. The interplay between gravity and the directional vibrations drives the material ahead. We are the best Vibro feeders Supplier.

Why Choose Kriimpas India Pvt. Ltd

- Customized Solutions, Rather Than Just Products: We recognize that each industry and application has distinct needs. Kriimpas India Pvt. Ltd. is outstanding in providing tailored vibro feeder solutions. Our skilled engineers collaborate with you to create and produce feeders that seamlessly fit into your current system and fulfill your precise requirements, whether you require a heavy-duty grizzly feeder for mining, a precise dosing feeder for pharmaceuticals, or a high-capacity unit for construction materials. This encompasses considerations regarding material type, flow rate, environmental conditions, and the preferred levels of automation.

- Sturdy Engineering and Unyielding Quality: Our vibro feeders are designed to endure the demands of ongoing industrial use. To guarantee long-term reliability and durability, as well as a lengthy operational life, we employ top-tier materials, exacting production methods, and strong drive mechanisms (electromechanical and electromagnetic). Our products are engineered for minimal wear and tear, which lowers the necessity for regular maintenance and replacement components.

- Advanced Control and Automation: The vibro feeders produced by Kriimpas India Pvt. Ltd. feature advanced control systems, enabling accurate feed rate adjustments, integration with supervisory control systems (SCADA/DCS), and alignment with Industry 4.0 initiatives. By automating processes to this degree, their efficiency is improved, the incidence of human error diminished, and performance can be optimized through the use of real-time data.

- Extensive Competence in Material Handling: Kriimpas India Pvt. Ltd. offers a complete range of material handling systems, not just vibro feeders. As a result, we can flawlessly incorporate your vibro feeder with other machinery such as conveyors, storage silos, weigh batching systems, and packing units, delivering a comprehensive and optimized solution from one dependable provider. We possess expertise that encompasses the whole material flow, guaranteeing seamless transitions and optimal efficiency.

- Committed After-Sales Support: We go above and beyond for our clients, well after the first sale. Kriimpas India Pvt. Ltd. offers a quick and effective after-sales service that encompasses installation support, commissioning, operator training, spare parts provision, and maintenance help. This guarantees minimal downtime for your vibro feeders while maintaining their performance.

- Established Track Record and Sector Confidence: Kriimpas India Pvt. Ltd. has developed a solid reputation for providing dependable solutions and gaining the trust of its clients, thanks to its years of experience serving various industries across India. The evidence of our competence lies in the successful installations we have completed and the satisfied customers we serve.

- Industrial Primary Grizzly Vibrating Feeders: Built to withstand heavy shock loads from trucks and loaders, these feeders feature strong grizzly bars for efficient scalping, safeguarding your primary crushers and enhancing throughput in mining and quarrying activities.

- Electromagnetic Vibratory Feeders: Suitable for applications that demand accurate dosing, immediate start/stop actions, and careful adjustments of feed rates, perfect for the pharmaceutical, food processing, and chemical sectors.

Applications of Vibro Feeders

- Iron Ore Pelletization Plants: Our robust electromechanical vibro feeders play a vital role in large-scale pelletization plants by ensuring the steady supply of iron ore fines, binders, and additives into balling drums or mixers. It is essential for the continuous and energy-intensive pelletizing process to manage large volumes while keeping a constant flow, as this has a direct effect on steel production quality and output.

- Thermal Power Plants (Coal Handling): At large-scale thermal power generation facilities, Kriimpas India’s vibro feeders play a vital role in the coal handling plant. They extract raw coal from bunkers with reliability and transfer it onto conveyor belts that lead to crushers and pulverizers. Thanks to its sturdy design, the fuel supply to the boilers remains unbroken even when large abrasive lumps of coal are used. This directly affects the power generation capacity.

- Large Stone Crushing Units: These units are essential for large-scale infrastructure projects, as they handle vast amounts of aggregates. Our grizzly vibro feeders are installed ahead of primary jaw crushers, effectively removing undersized material and providing oversized rocks at a controlled rate. By improving crusher efficiency, reducing wear and tear, and enhancing the quality of the crushed product, this pre-screening helps to speed up construction timelines.

- Fertilizer Manufacturing Facilities: Accurate dosing of raw materials (such as rock phosphate, potash, and urea) is crucial for chemical reactions and the quality of the final product in the production of fertilizers. Kriimpas India’s electromagnetic vibro feeders guarantee precise and contamination-free delivery of these granular and powdery components during various processing stages, aiding in the maintenance of consistent quality for the nation’s agricultural inputs.

- Steel Melting Shops: In integrated steel plants, vibro feeders are used to introduce different charge materials, alloys, and fluxes into electric arc furnaces or induction furnaces. These feeders are built to manage high temperatures and the abrasive characteristics of the materials, guaranteeing a consistent charge and an optimized melting process—essential for effective steel production.

- Mining and Quarrying: This sector represents a significant application in India, especially for coal, iron ore, and aggregates. Vibro grizzly feeders serve to separate oversized material prior to crushing, guaranteeing a consistent feed to the crushers and safeguarding them from harm. They also allow for efficient loading onto trucks or conveyor belts.

- Construction and Infrastructure: Vibro feeders provide the reliable supply essential for major infrastructure projects, from supplying raw materials such as sand and gravel to concrete batching plants to managing aggregates for road construction.

Table Specifications of Vibro Feeders

| Parameter | Specification |

|---|---|

| Product | Vibro Feeders |

| Feeding Capacity | 0.5 TPH to 500 TPH |

| Tray Length | 500 mm to 3500 mm |

| Tray Width | 300 mm to 1200 mm |

| Vibrating Frequency | 50 Hz / 60 Hz |

| Drive Type | Electromagnetic / Electromechanical |

| Power Supply | 230V / 415V AC, 50 Hz |

| Material of Construction | Mild Steel, Stainless Steel (SS-304, SS-316) |

| Controller Type | Variable Voltage Controller |

| Installation Type | Mounted / Suspended |

| Application Industries | Mining, Food, Pharma, Cement, Chemical, Automotive |

| Customization | Available |

Types of Vibro Feeders

Electromagnetic Vibro Feeders

- These feeders use electromagnetic coils to create vibrations. They are ideal for applications requiring precise material flow and frequent feed rate adjustments. Electromagnetic feeders are commonly used in industries like pharmaceuticals, food processing, and chemicals.

Key Features:

- Adjustable feed rates

- Energy-efficient

- Highly reliable for small to medium material sizes

Electromechanical Vibro Feeders

- Electromechanical feeders are powered by unbalanced motors or vibratory drives mounted on the feeder body. They are suitable for handling larger and bulkier materials such as stones, minerals, or metal scraps.

Key Features:

- Robust design for heavy-duty applications

- Uniform material flow

- Low maintenance

Tubular Vibro Feeders

- These feeders come with a tubular design that ensures dust-free and contamination-free material transfer. Tubular vibro feeders are extensively used in the food, pharmaceutical, and chemical industries.

Key Features:

- Enclosed structure

- Hygienic material handling

- Ideal for fine powders and sensitive materials

Grizzly Vibro Feeders

- Grizzly feeders are equipped with a screening section, allowing fine materials to bypass the crusher or processing unit. They are highly effective in primary feeding operations in mining, stone crushing, and aggregate processing.

Key Features:

- Heavy-duty design

- Integrated screening capability

- High feed capacity

Furnace Charging Vibro Feeders

- Specially designed for metallurgical industries, these feeders are used for charging materials like scrap and additives into furnaces.

Key Features:

- Heat-resistant build

- Controlled and safe operation

- Customizable for various furnace types

Conclusion

Vibro feeders serve purposes beyond those of mere machines; they are the finely-tuned devices that guarantee the seamless, effective, and regulated transfer of goods that constitute the bedrock of contemporary industry. Their role is essential, ranging from large-scale mining activities to intricate pharmaceutical procedures. We are the best Best Vibro feeders Provider.

In the context of India’s fast-evolving industrial sector, opting for a trustworthy Vibro Feeders Provider is essential for attaining operational excellence. Kriimpas India Pvt. Ltd. is that reliable collaborator, providing a combination of state-of-the-art technology, solid construction, diverse product options, and unmatched customer assistance. Our commitment lies in equipping Indian industries with the most dependable and effective material handling solutions.