Film Extrusion Lines Provider

Film Extrusion Lines/Film Extrusion Lines Provider/Film Extrusion Lines Supplier/Film Extrusion Lines Dealer/Blown Film Extrusion Lines Provider/

Table of Contents

Introduction

Welcome to Kriimpas India Pvt. Ltd., where we offer comprehensive solutions for all your material processing needs. Since 2012, we have been dedicated to providing top-notch machinery and services to our valued customers. We are the best Film Extrusion Lines Provider.

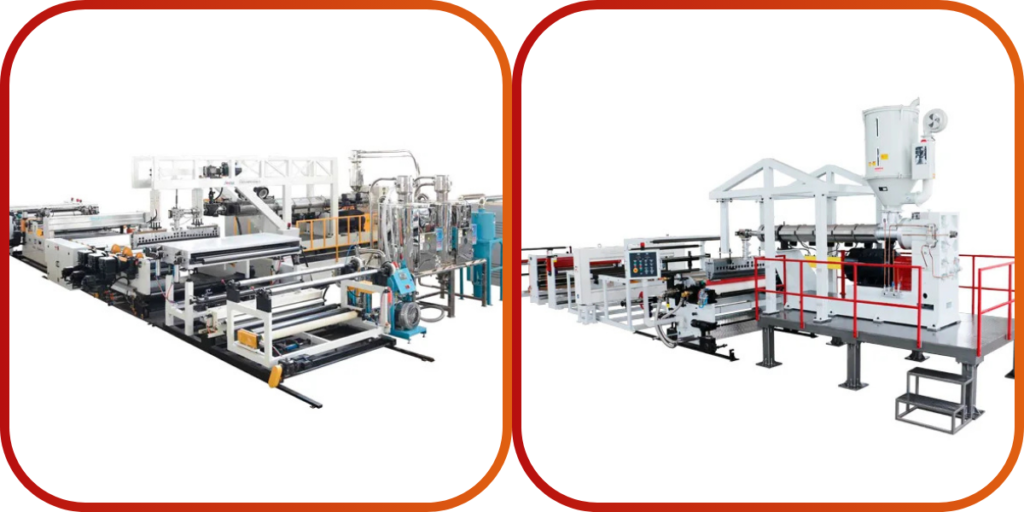

Technologies for plastic processing are essential to the production of a wide range of goods used in everything from packaging to agriculture in today’s industrial environment. The film extrusion line, a device that turns raw plastic components into thin plastic films with a variety of uses, is one of the most effective and popular technologies.

Look no farther than Kriimpas India Pvt. Ltd., a prominent supplier of plastic processing machinery and related services in Ahmedabad, if you’re searching for a trustworthy supplier of Film Extrusion Lines. The film extrusion process, its uses, advantages, and the reasons Kriimpas India Pvt. Ltd. is the go-to partner for premium extrusion lines are all discussed in detail in this article.

What is a Film Extrusion Line?

A film extrusion line is an advanced piece of machinery that melts and discharges polymers to create thin plastic films. These films are frequently used in industrial products, laminations, packaging, and agricultural coverings. In order to create a consistent film, the molten plastic is shaped through a die, heated raw polymer resins, and then cooled.

Components of a Film Extrusion Line

Key elements of a typical film extrusion line include the following:

- Extruder: At the centre of the film extrusion process is the extruder. It is in charge of melting and combining the polymer resins, which are often pellet-shaped, to produce a uniform melt. The molten material is forced through the barrel and into the die by the extruder using a spinning screw.

- Film Blade: A thin layer of molten polymer is formed by the film die. For the film to have the correct thickness and qualities, the die’s design is essential. In cast film extrusion, the film is laid flat, while in blown film extrusion, the die forms a tube that is inflated to create a bubble.

- Cooling System: To maintain its shape and qualities, the molten plastic must be rapidly cooled once it was up through the die. This happens using a cooling system that uses either water-based or air-based techniques.

- Winding Unit: A winding unit winds the cooled film into big rolls. These rolls can be sold straight to clients for packaging and other uses, or they can be utilised for additional processing.

- Control System: The control system is in charge of controlling the extrusion process’s temperature, speed, and pressure, among other elements. With their sophisticated automation, modern film extrusion plants guarantee reliable and superior output.

- Masterbatches and Additives: To improve the qualities of the finished film, stabilisers, UV inhibitors, and colourants can be included with the polymer resin. These are frequently added at the masterbatch feeding unit or extruder.

Applications of Film Extrusion Lines

There are several uses for film extrusion lines in different sectors. Among the most widely used applications are:

- Packaging

The packaging industry is one of the most frequent uses for film extrusion lines. The resulting films are used to make bags for both food and non-food items, pouches, and product packaging. High-quality films are essential to the packaging industry’s ability to safeguard and display its products. - Agriculture

Film extrusion lines are utilised in the agricultural sector to create mulch films, greenhouse covers, and other protective agricultural coverings. These coatings shield plants from environmental elements like pests and UV radiation while also increasing crop yields. - Medical

Extrusion-line films are used in the medical sector to package medications, medical machinery, and other healthcare supplies. To guarantee the safety of the product, the films are usually sterile and protective. - Construction

Formed films are utilised in construction as vapour barriers, insulation, and protective coverings for building supplies. - Consumer Goods

Films are used to package and protect a variety of consumer goods, including apparel and electronics, while they are in transportation.

Why Choose Kriimpas India Pvt. Ltd.: Best Film Extrusion Lines Provider

One of India’s top suppliers of premium film extrusion lines is Kriimpas India Pvt. Ltd. Our speciality is providing modern technology that guarantees dependable, effective, and environmentally friendly filmmaking. We are the best Film Extrusion Lines Supplier. Kriimpas India is your preferred supplier for film extrusion lines for the following reasons:

- Technological Innovation

To provide the greatest film extrusion lines in the business, Kriimpas India Pvt. Ltd. makes investments in state-of-the-art equipment. The newest automation technologies installed in our machinery increase production efficiency, save energy costs, and guarantee constant product quality. Our extrusion lines are designed to fit your individual demands, whether you’re making high-performance films or basic packaging films. - Customisation Choices

We are aware that each client has particular needs. For this reason, we provide extremely adaptable film extrusion lines that may be customised to meet your production requirements. From blown film to cast film extrusion, and from monolayer to multilayer systems, we can offer solutions that precisely match your needs. - Superior Performance

At Kriimpas India, we put quality first. To guarantee smooth and reliable performance over time, our film extrusion lines are constructed with sophisticated parts and long-lasting materials. Our machinery is built using the best materials available, which reduces downtime and extends the equipment’s lifespan. - Efficiency in Energy Use

We are aware of the importance that energy efficiency and sustainability are in the modern manufacturing setting. The film extrusion lines from Kriimpas India are made to use the least amount of energy possible, which lowers running expenses and the environmental effect of your production its activities. Our effective designs guarantee that your production is economical and environmentally responsible. - All-inclusive Afterwards Help

Kriimpas India Pvt. Ltd. cultivates strong relationships with our customers rather than only selling them a product. Training, upkeep, and troubleshooting are all part of our after-sales service to make sure your extrusion lines function properly. We offer dependable and timely client support to help you maintain smooth business activities. - Experience in the Industry

Kriimpas India Pvt. Ltd. has years of experience in the business and a full understanding of the demands and difficulties experienced by manufacturers in the film extrusion sector. From choosing the best extrusion line to maximising production efficiency, our team of professionals is always available to help. - Economical Remedies

We are committed to providing premium goods at affordable costs. Our film extrusion lines are built to last by providing excellent performance, low maintenance and energy economy. Investing in machinery from Kriimpas India Pvt. Ltd. would yield a high return on investment (ROI) in the long run.

Benefits of Film Extrusion for Your Business

Your company may be greatly impacted by your choice of film extrusion line supplier. Purchasing film extrusion lines from Kriimpas India Pvt. Ltd. has the following advantages:

- Improved Efficiency in Production

Our advanced extrusion lines are built to be as efficient as possible. Your production lines will run more efficiently with shorter downtime, automated controls, and quicker cycle times. - Higher-quality Products

Purchasing excellent film extrusion lines can guarantee that the films you make are of the highest calibre. Our lines give you exact control over the films’ thickness, texture, and other characteristics, guaranteeing that your final products live up to the highest requirements. - Flexibility in Using Films

Our film extrusion lines serve a broad range of applications, from high-performance films to simple packaging. Our technologies can create films that are customised to your particular requirements, whether you’re producing agricultural, medicinal, or flexible packaging films. - Lower Running Expenses

Our film extrusion lines contribute to lower maintenance expenses with their effective designs that maximise energy utilisation and minimise material waste. This enables you to remain profitable while providing your clients with competitive prices. - Environmental Friendliness and Sustainability

Kriimpas India Pvt. Ltd., a top supplier of film extrusion lines, is dedicated to sustainability. Our machinery is made to use less energy, use materials more efficiently, and produce less waste, all of which help to make production more sustainable and green.

Conclusion: Film Extrusion Lines Provider

Film extrusion lines are essential for creating high-quality films for a range of uses, such as packaging, farming, medicine, and more. Selecting the best film extrusion line supplier is essential for guaranteeing effective, economical, and superior output. We are the best Film Extrusion Lines Dealer.

Kriimpas India Pvt. Ltd. is your reliable partner for innovative film extrusion lines that satisfy the various demands of the modern manufacturing sector. We are the best option for companies wishing to invest in film extrusion equipment because of our innovative products, flexible solutions, and dedication to quality.

By selecting Kriimpas India Pvt. Ltd., you are investing in your company’s future growth rather than merely modern machinery. Allow us to use our dependable, high-performance film extrusion lines to help you advance your production.

For more information about our film extrusion lines and how we can help your company achieve higher productivity, quality, and profitability, get in touch with Kriimpas India Pvt. Ltd. right now.